Consumable container with circuit for measuring consumable surplus

A technology of consumables and remaining quantity, which is applied in printing and other directions, and can solve problems such as the increase in the cost of ink cartridge manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described in the following order.

[0025] A. the structure of the ink cartridge in the embodiment of the present invention;

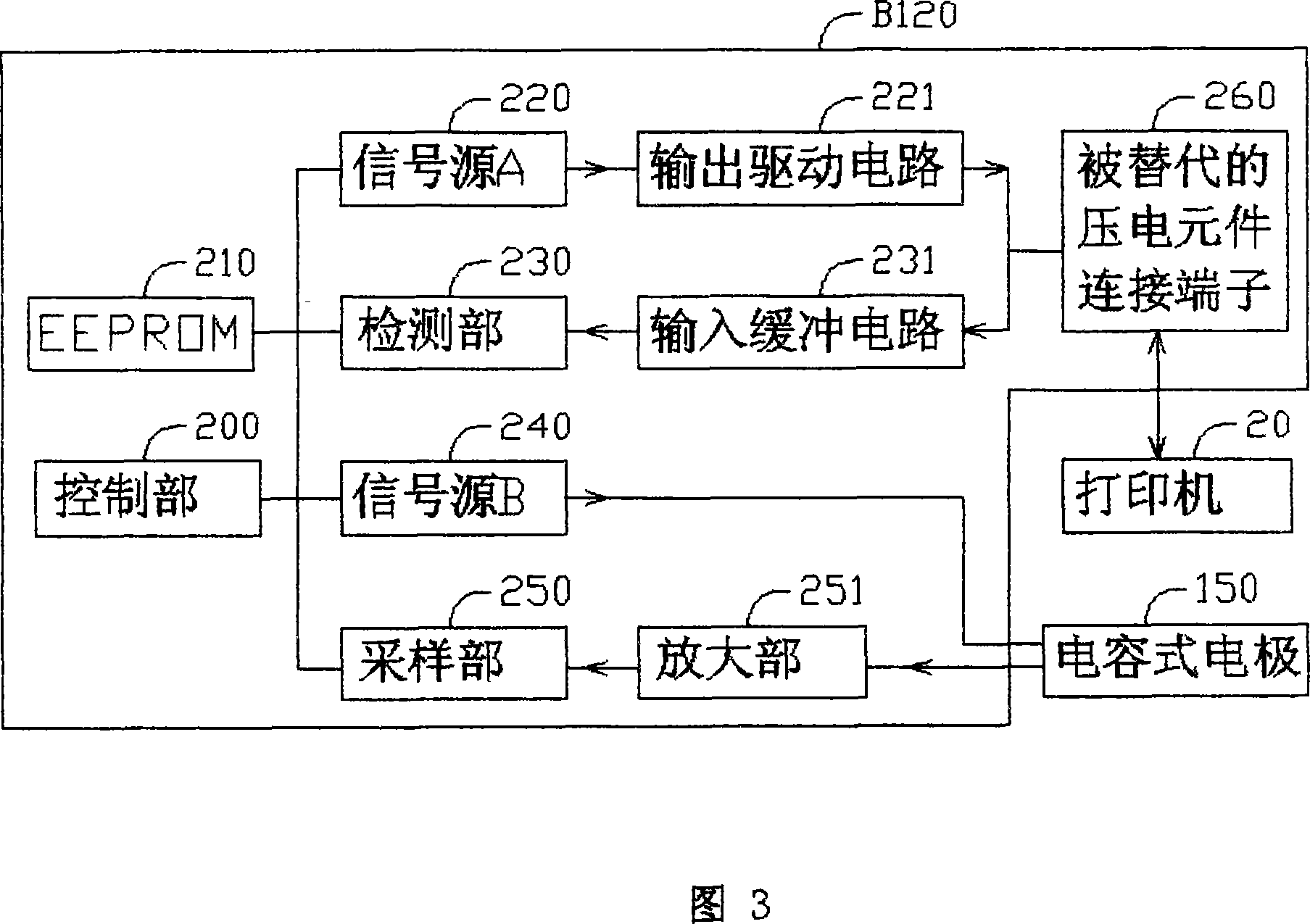

[0026] B. the electrical structure of the ink cartridge in the embodiment of the present invention;

[0027] C. Circuit principle of the replaced piezoelectric element charging and discharging waveform generation part in the embodiment of the present invention;

[0028] D. The principle of the input buffer circuit in the embodiment of the present invention;

[0029] E. The voltage waveform generation process on the replaced piezoelectric element terminal in the embodiment of the present invention;

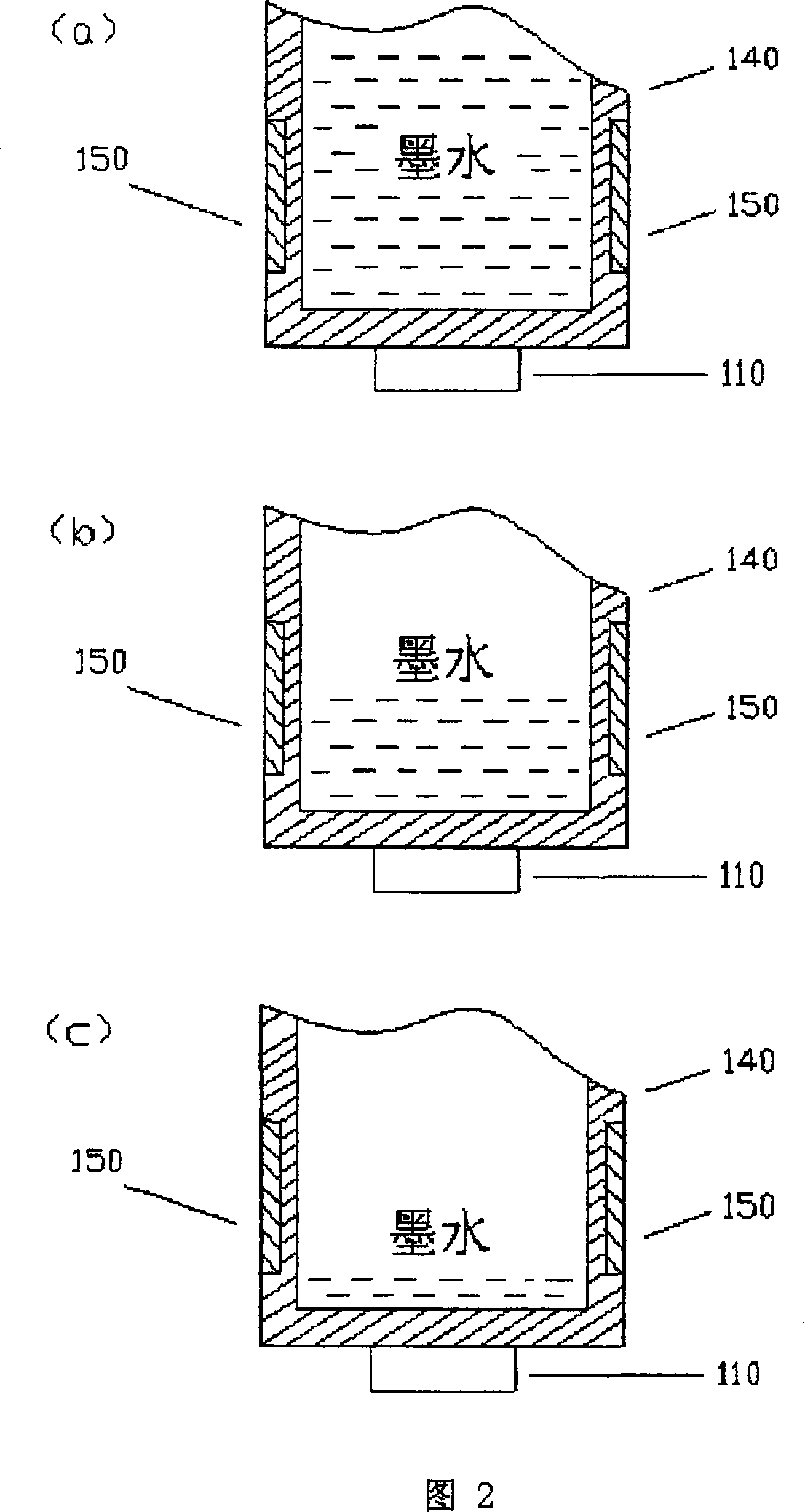

[0030] F. The working principle of the capacitive electrode in the embodiment of the present invention;

[0031] A. The structure of the ink cartridge:

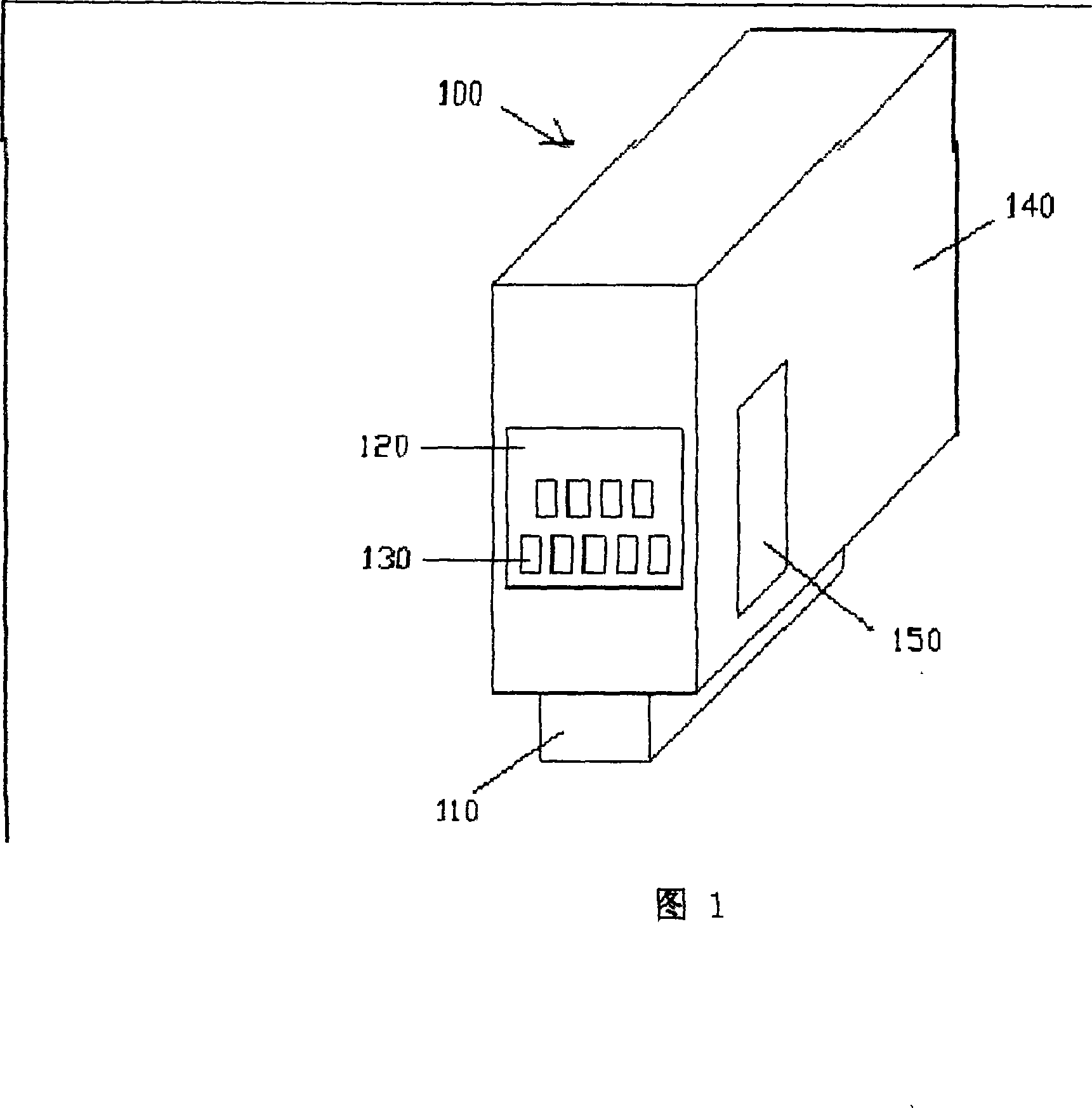

[0032] FIG. 1 is an external view of an ink cartridge 100 in an embodiment of the present invention. The ink cartridge 100 includes a cartridge body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com