Whole liquid phase isothermal urea synthesis method and its special equipment

A synthesis method and urea technology, which are applied in chemical instruments and methods, preparation of organic compounds, preparation of urea derivatives, etc., can solve the problems of low carbon dioxide conversion rate, easy corrosion of urea synthesis tower, high energy consumption, etc. The effect of liquid phase reaction area, increasing the utilization of effective space, and improving the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

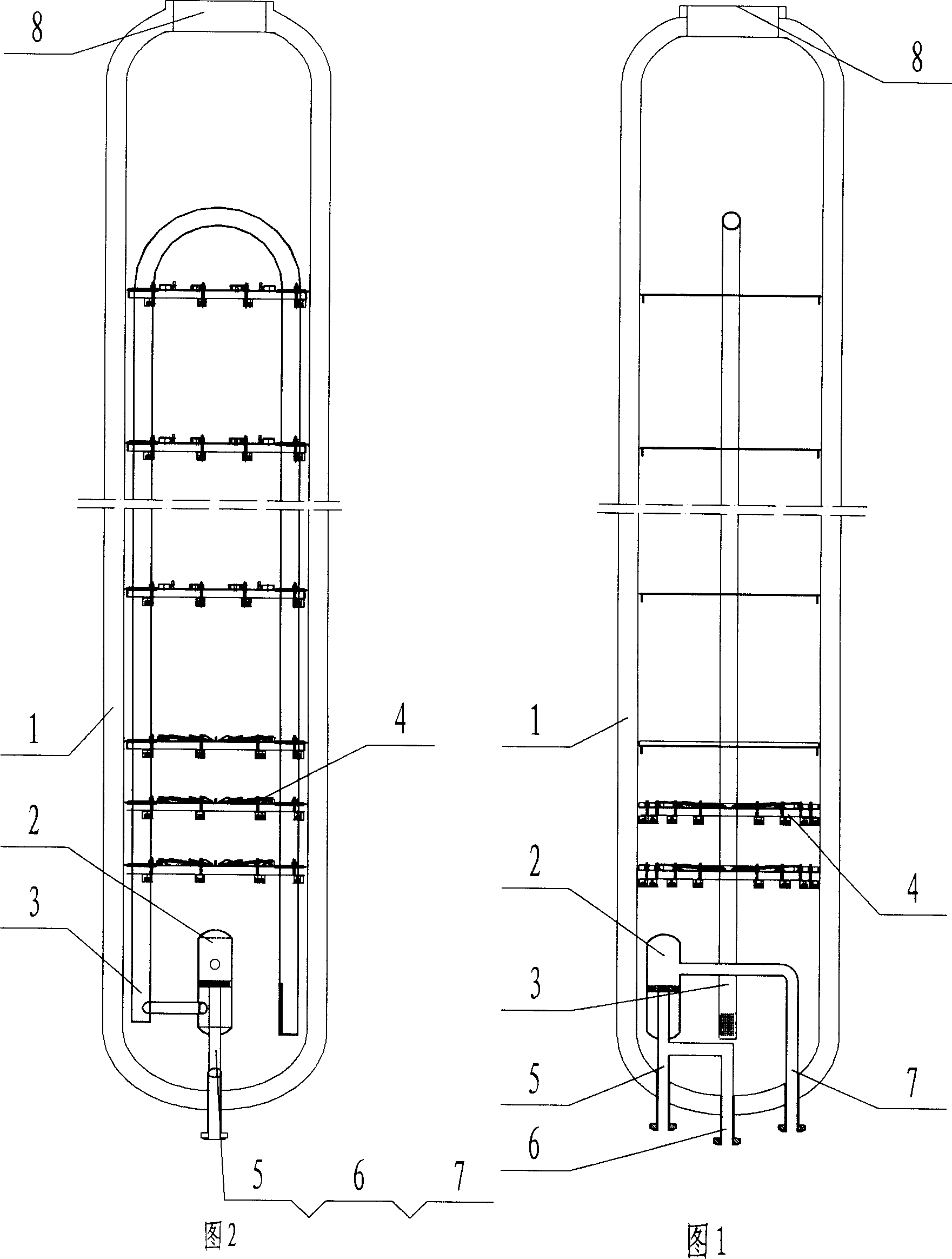

[0014] Embodiment 1, referring to Fig. 1, 2, process and make tower body 1, offer liquid ammonia inlet 5, carbon dioxide inlet 6 and first liquid inlet 7 at the bottom of tower body 1, offer discharge port 8 at its top, in tower body 1. A liquid atomization reactor 2 is installed inside. The liquid atomization reactor 2 communicates with the liquid ammonia inlet 5, the carbon dioxide inlet 6 and the first liquid inlet 7, and then installs a high-efficiency tray 4 on the inner wall of the middle and upper part of the tower body 1. The high-efficiency tray 4 is multi-layer, and the heat exchange pipe 3 is installed on the high-efficiency tray 4. The heat exchange pipe 3 can be "U" type or "S" type. The heat exchange pipe 3 and the liquid atomization reactor 2 Communication; liquid atomization reactor 2, heat exchange pipe 3, and high-efficiency tray 4 are made of urea grade 316Lmod, TA2, and zirconium materials.

[0015] Then add liquid ammonia, carbon dioxide and a liquid to th...

Embodiment 2

[0016] Embodiment 2, the urea synthesis tower is the same as embodiment 1, the difference is that liquid ammonia, carbon dioxide and a liquid ammonia are added to the corresponding feed port in the tower, and the feed NH 3 / CO 2 Molecular number ratio 4.0, H 2 O / CO 2 Molecular number ratio is 1.0; liquid ammonia and first liquid react with carbon dioxide instantly and thoroughly after atomization in the liquid atomization reactor to generate ammonium carbamate solution, which first enters the heat exchange pipe and enters the urea synthesis from the other end of the heat exchange pipe At the bottom of the tower, the temperature inside the tower is 190°C and the pressure is 19MPa; the ammonium carbamate solution completes the dehydration reaction in the urea synthesis tower to generate urea, which is discharged from the discharge port, and the conversion rate of carbon dioxide is detected to be 75%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com