Production method of hexamethoxy methyl melamine resin

A technology of hexamethoxymethyl melamine and a production method, which is applied in the production field of hexamethoxymethyl melamine resin, can solve problems such as environmental pollution, damage to the health of operation and work, and achieve the effects of wide compatibility and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

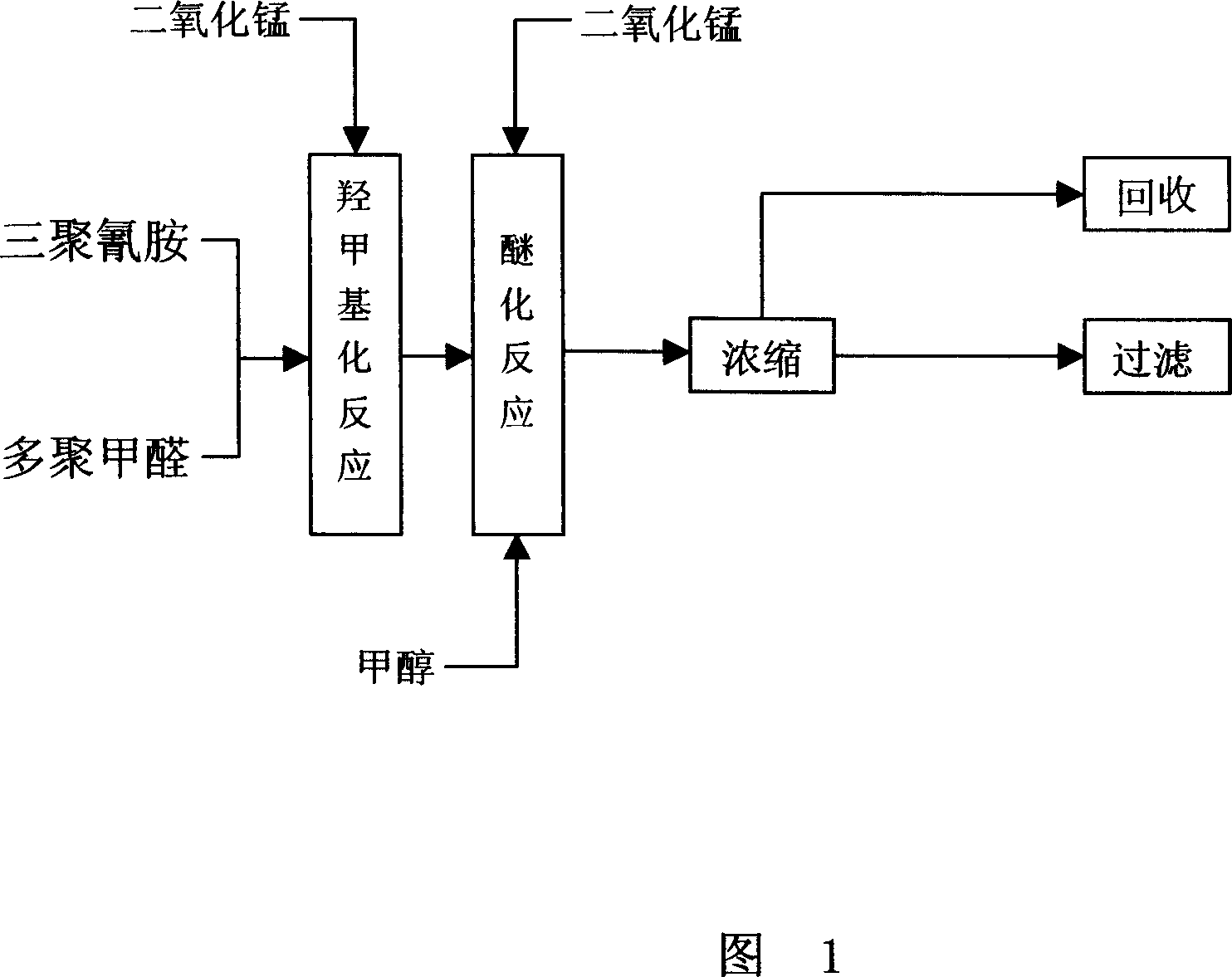

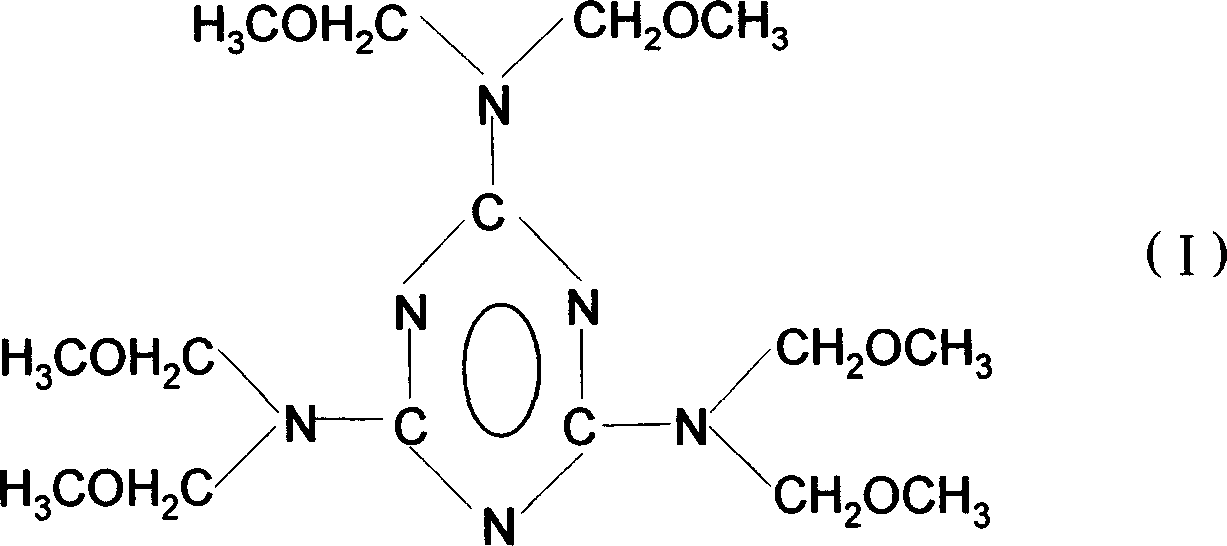

[0009] As shown in Figure 1, add melamine and excess paraformaldehyde into the reaction kettle, the molar ratio of paraformaldehyde to melamine should be greater than 10, and under normal pressure, the temperature should be controlled at 30-35°C, and the moisture should be controlled at 5-15 %, by adding an appropriate amount of manganese dioxide catalyst for methylolation reaction, an intermediate product is generated; after 3 to 4 hours, the methylolation reaction is basically completed, and then excessive methanol is added, wherein methanol and the original The molar ratio of melamine should be greater than 8, and the temperature rises to 50-75°C. Also under the action of manganese dioxide catalyst, after about one hour, the etherification reaction is basically completed, and methanol-etherified melamine with high etherification degree is produced, namely: Hexa Oxymethylmelamine.

[0010] There is no three wastes generated in this process. Since a certain amount of formalde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com