Preparation method of multifunction organic metal initiator for anionic polymerization

An organic alkali metal and anionic polymerization technology, which is applied in the field of preparation of multifunctional organic alkali metal initiators for anionic polymerization, can solve problems affecting polymer quality, unfavorable long-term maintenance of initiator activity, and affecting initiator functionality. The effect of low production cost, less equipment demand, and less waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

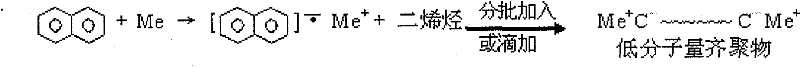

Method used

Image

Examples

Embodiment 1

[0052] Add 22 mmoles of lithium naphthalene to a purified 250 mL polymerization bottle with electromagnetic stirring. Add 100 mL of butadiene-cyclohexane solution with a concentration of 60 g / L in four times, and react at 25° C. for half an hour after each addition. After the reaction was completed, 2.7 mmoles of tin tetrachloride solution was added, and the reaction was stopped at 25° C. for another 1 hour. The product is a polyfunctional organolithium initiator with an average functionality of 3.7.

Embodiment 2

[0054] Add 25mL of cyclohexane solution of butadiene to the purified 250mL polymerization bottle with electromagnetic stirring, the monomer concentration is 60 g / L, add 22 mmoles of lithium naphthalene, react at 25°C for half an hour, and then keep the reaction temperature at At 25°C, 75 mL of isoprene-cyclohexane solution was added dropwise within 1 hour, and reacted at 25°C for half an hour after all the addition was completed. Add 2.5 mmol tin tetrachloride solution, and stop the reaction after reacting at 25°C for 1 hour. The product is a polyfunctional organolithium initiator with an average functionality of 2.5.

Embodiment 3

[0056] Add 13mL of butadiene-cyclohexane-hexane solution to the purified 250mL polymerization bottle with electromagnetic stirring, the monomer concentration is 80 g / L, cyclohexane: hexane is 80:20, add naphthalene lithium 20 Millimole, react at 25°C for half an hour; then add butadiene solution 13mL, 14mL, and 14mL in three batches, and react at 25°C for half an hour after each addition. After the reaction was completed, 2.5 mmoles of tin tetrachloride solution was added, and the reaction was stopped at 25°C for another 1 hour. The product is a polyfunctional organolithium initiator with an average functionality of 3.8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com