Construction process of poured pile with steel pipe as wall protecting casing

A technology of bored piles and wall casings, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve problems such as vibration, soil collapse, and inability to ensure subway safety, and achieve low noise, low vibration, Good social and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0039] The process principle of the present invention: use a full set of pipe pile machine to bite and press the steel pipe, and press the steel pipe into the soil while taking the soil. After the steel casing is connected with the special method of internal hexagonal burial, continue to bite and press the steel casing until it reaches the design elevation. , In the range of the buried depth of the full casing, because of the casing, there will be no hole collapse and hole expansion, and the soil will not move. In this way, the operation safety of the subway tunnel will not be affected, and the bored pile construction will be carried out after the full casing is pressed to the design elevation and the soil is taken.

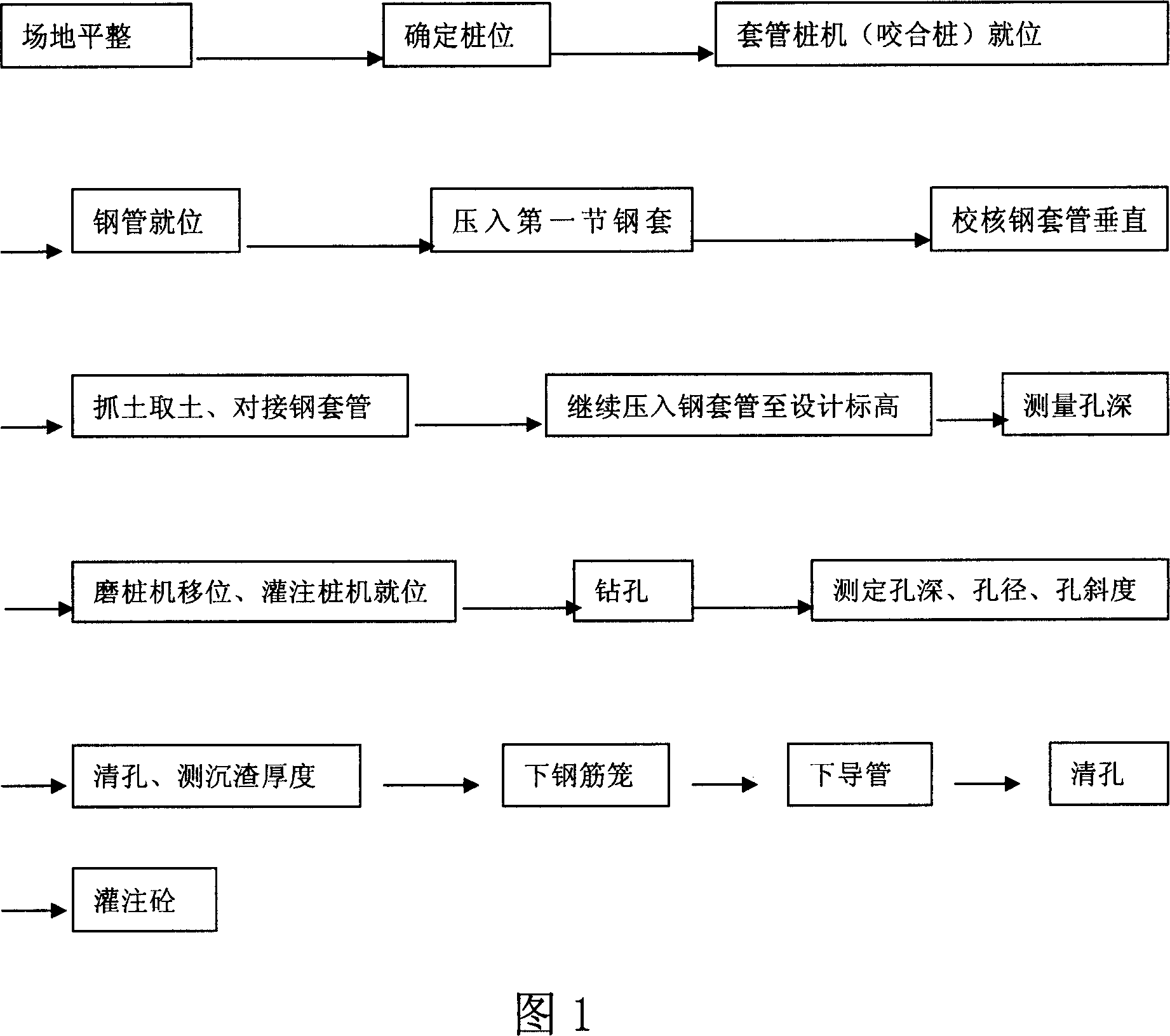

[0040] Process flow and operating points of the present invention:

[0041] 1. Process flow: as shown in Figure 1

[0042] 2. Key point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com