Blowed premixed efficient gas burner

A gas burner, premixed technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problems of incomplete combustion, low combustion temperature, de-firing, etc., and achieve improved combustion temperature and combustion stability. Good, the effect of promoting full combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

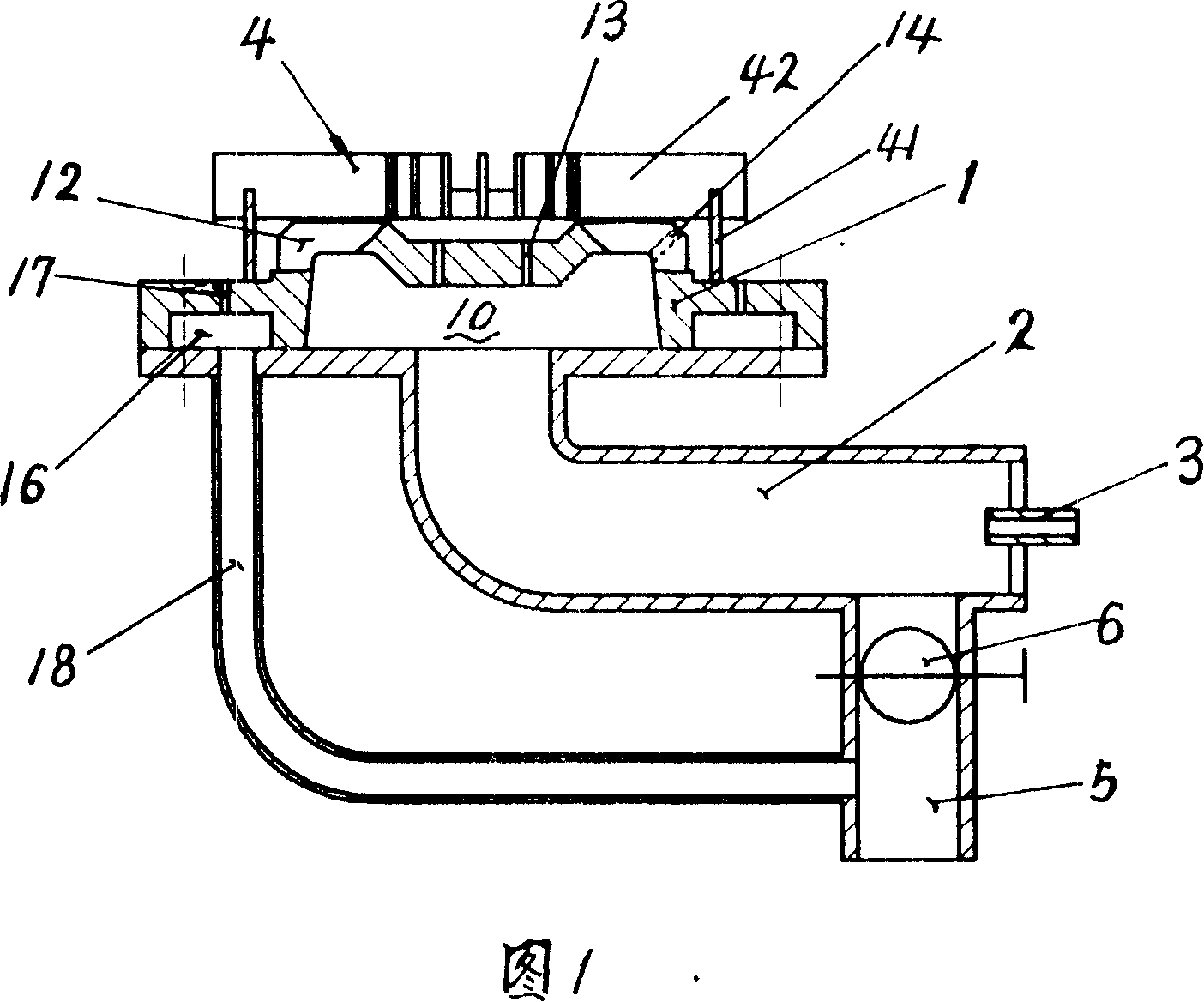

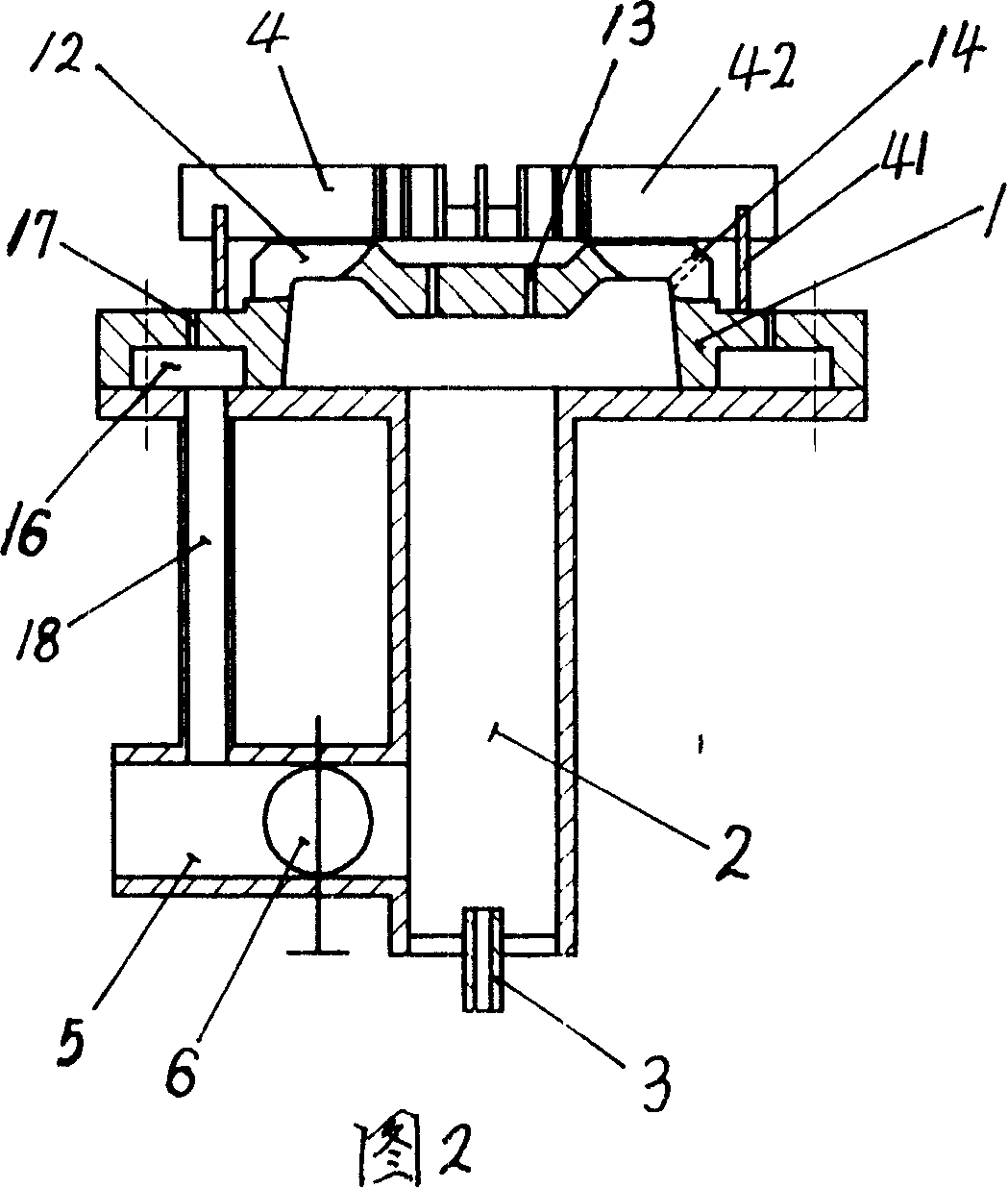

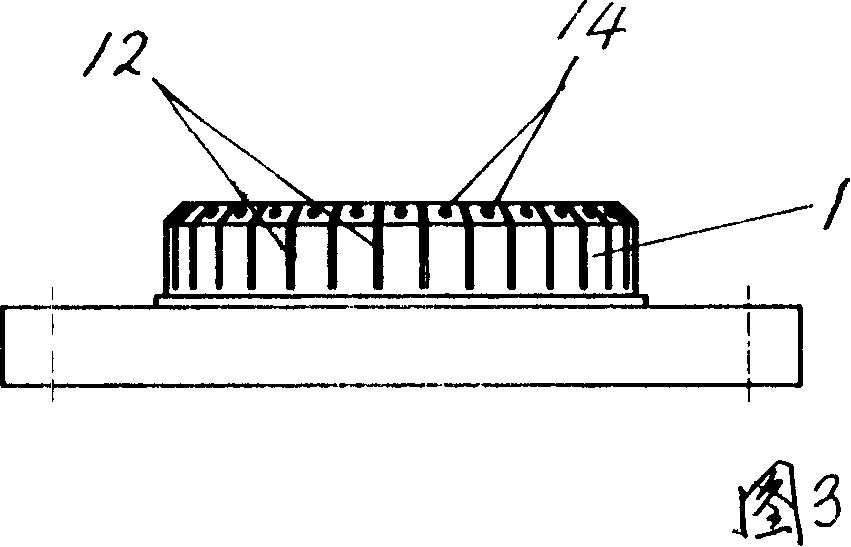

[0011] The present invention is composed of a burner head 1, a mixer 2, a gas nozzle 3, a combustion rectifier 4, an air inlet pipe 5, and an air inlet pipe damper 6. On the outer ring of the burner head 1, several strip-shaped The fire hole 12, the strip fire hole 12 is a strip hole connected upwards and sidewards, that is, a "" shaped gap strip hole, and a secondary air chamber 16 is opened on the outer end ring of the burner head 1. The secondary air outlet 17 is evenly distributed on the secondary air chamber 16, and the secondary air pipe 18 is arranged between the secondary air chamber 16 and the air inlet pipe 5. Composed of a number of vertical rectifiers 42 connected to the rectification ring 41, the combustion rectifier 4 is placed or fixedly connected to the burner head 1, the mixer 2 is horizontal or vertical, and the mixer 2 is docked with the burner head 1 Fixed connection.

[0012] In the present invention, several circular fire holes 13 are evenly distributed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com