Radiator and its manufacturing method, electronic equipment with radiator

A technology for electronic equipment and heat sinks, applied in circuits, electrical components, electric solid devices, etc., can solve the problem that the ratio of the length of the screw-like fins to the circumference cannot be made too large, the cost, efficiency and reliability of the heat sink are low, and the system Unsmooth flow field and heat dissipation requirements, etc., to achieve low thermal resistance and flow resistance, large design flexibility, and good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

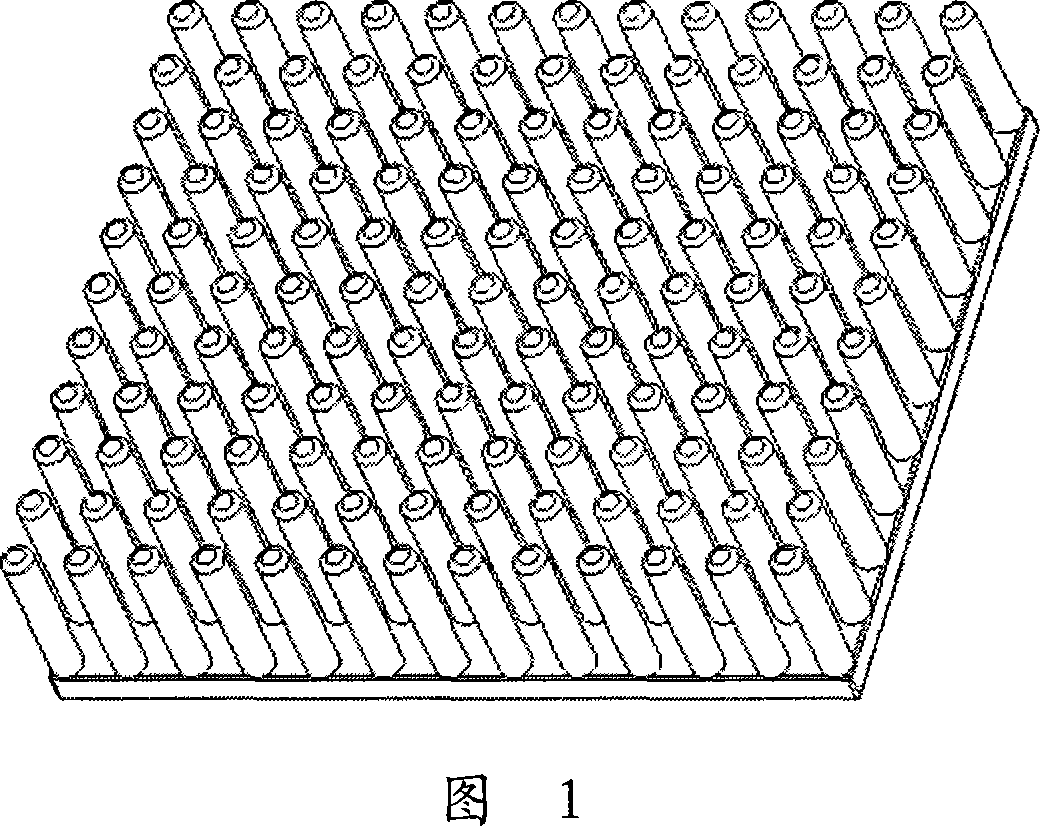

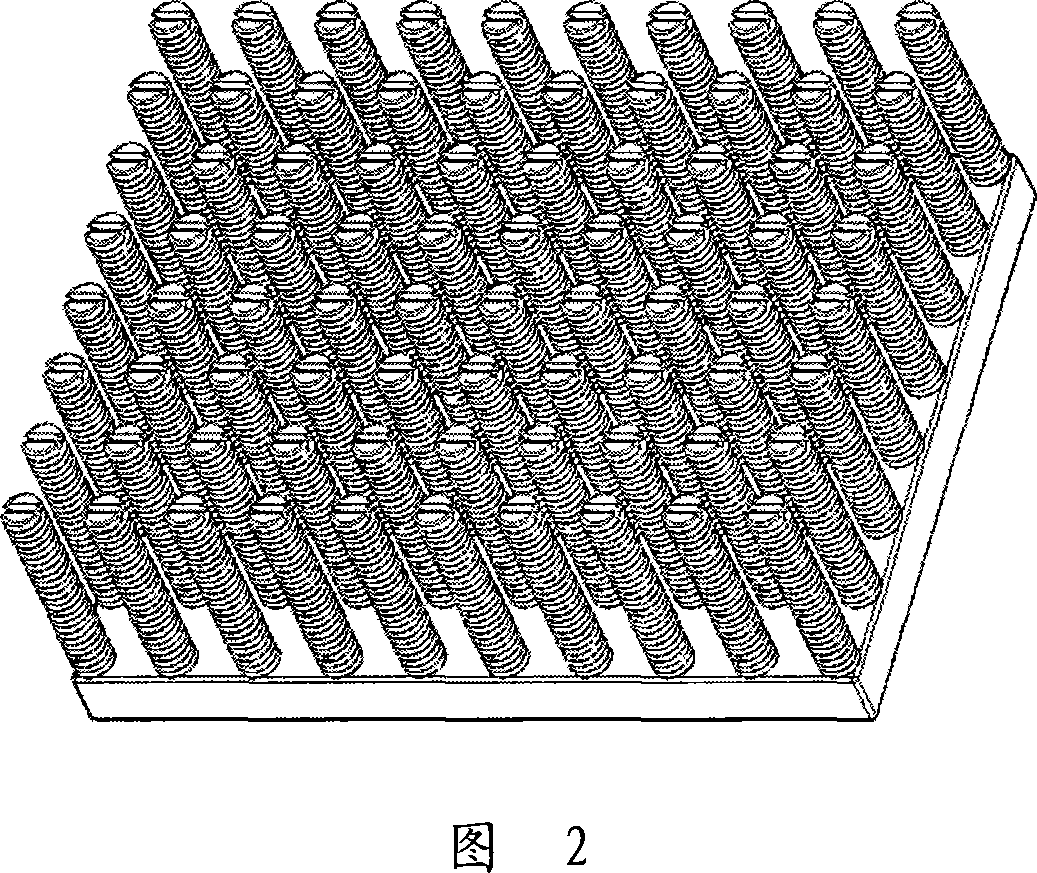

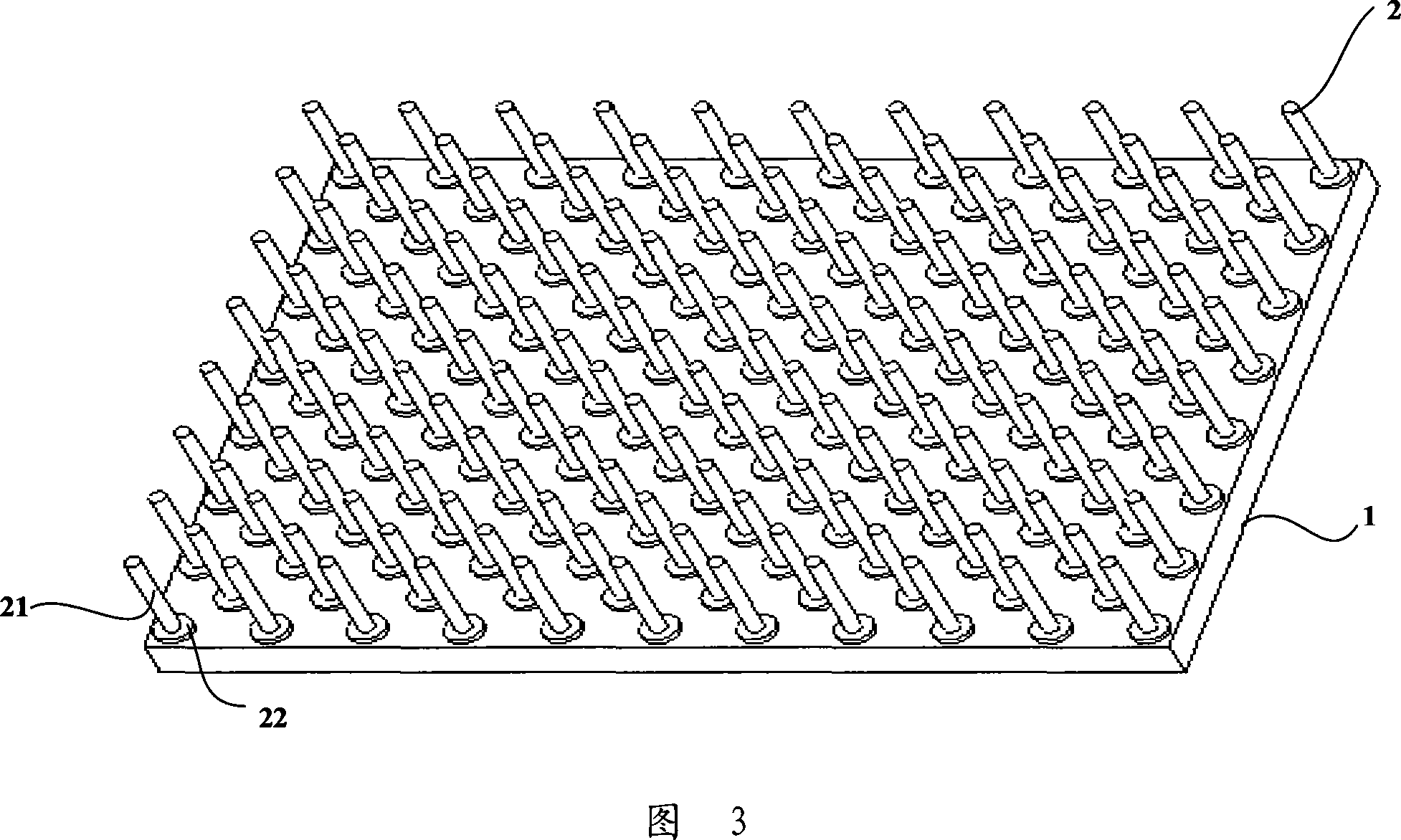

[0025] In the heat sink and its manufacturing method provided by the embodiments of the present invention, the base plate and the columnar fins of the heat sink are formed separately, and then the columnar fins of the heat sink are fixed on the base plate by welding or bonding to form a complete heat dissipation system. The radiator as a whole, or directly fixed into a whole radiator by mechanical means such as screws, can change the shape and array pattern of the columnar fins according to the actual application environment to design different radiator flow channels to achieve a good heat dissipation effect.

[0026] The technical solutions of the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0027] Referring to FIG. 3 , a schematic structural view of a heat sink according to an embodiment of the present invention is illustrated; according to this figure, a heat sink includes at least a substrate 1 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com