Water filter

A filter and water purification technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, adsorbed water/sewage treatment, etc., can solve problems such as need to be replaced, inconvenient to use, etc., and achieve excellent water purification efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

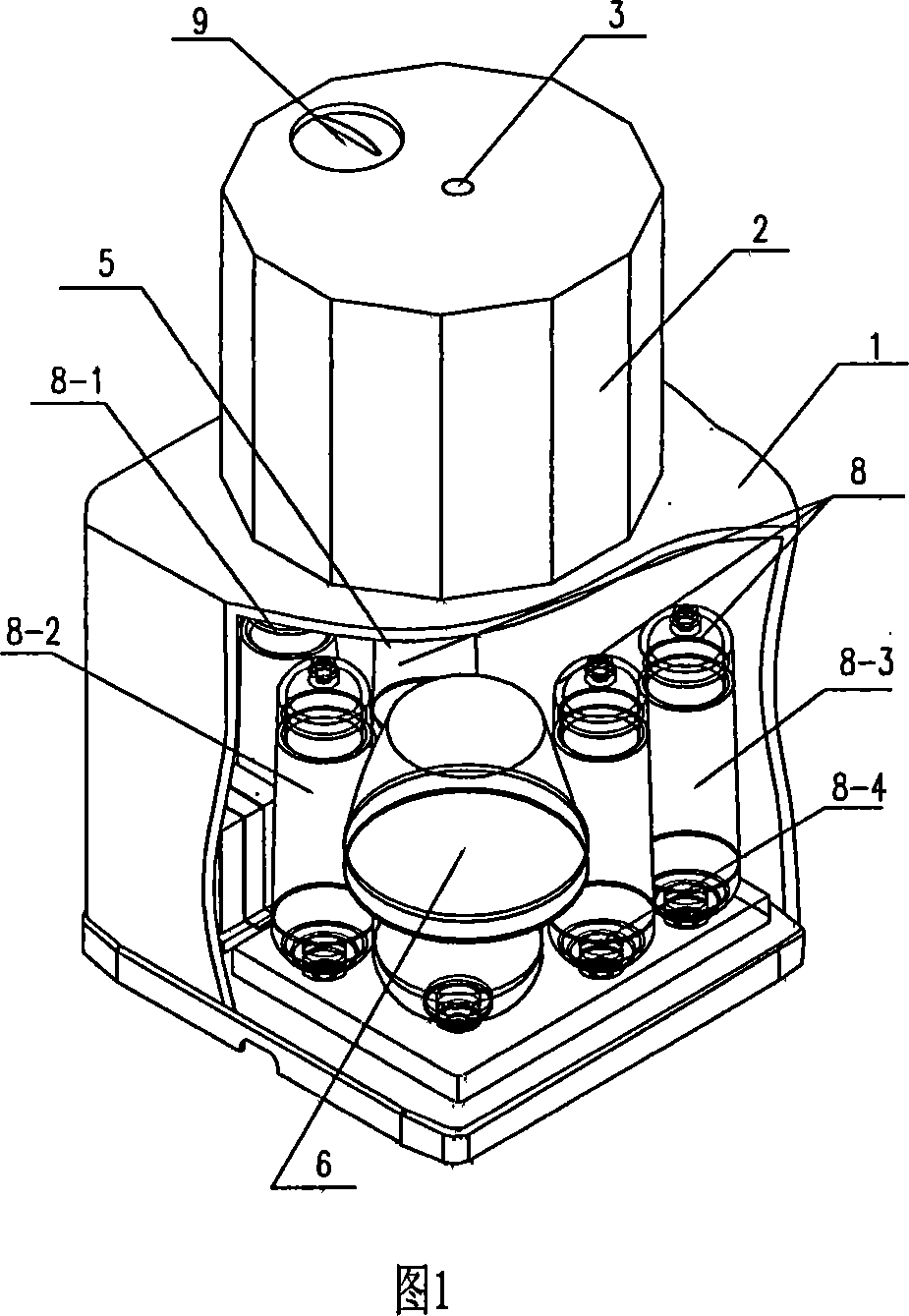

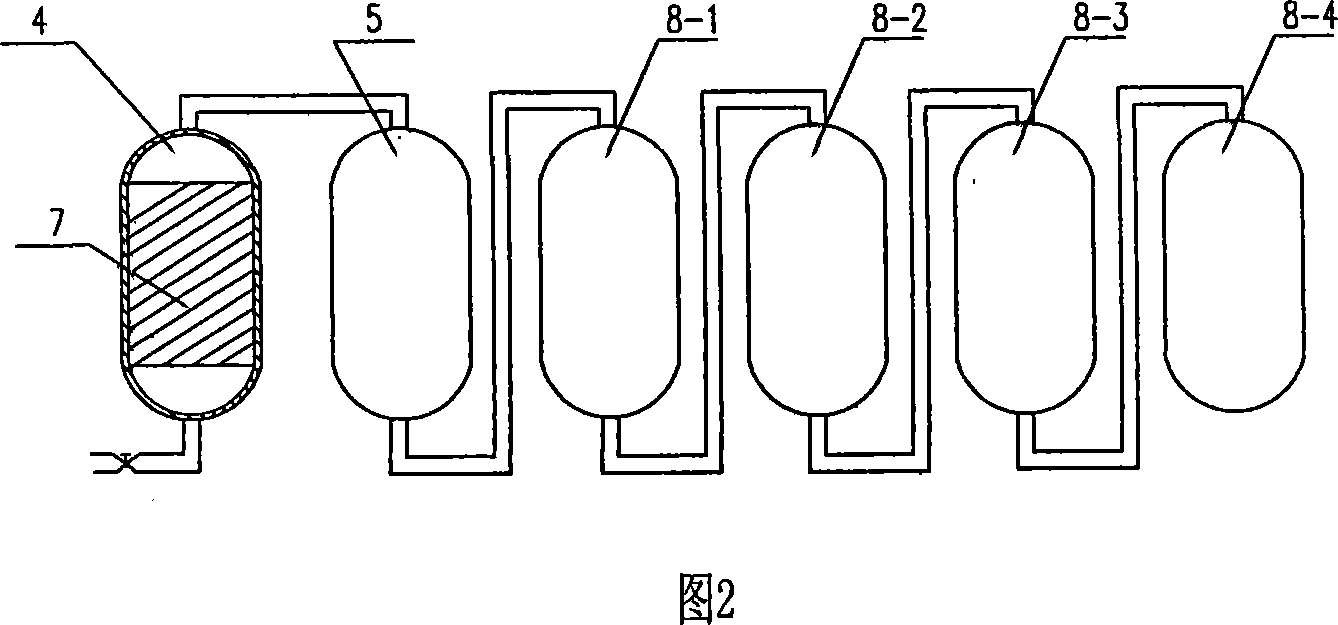

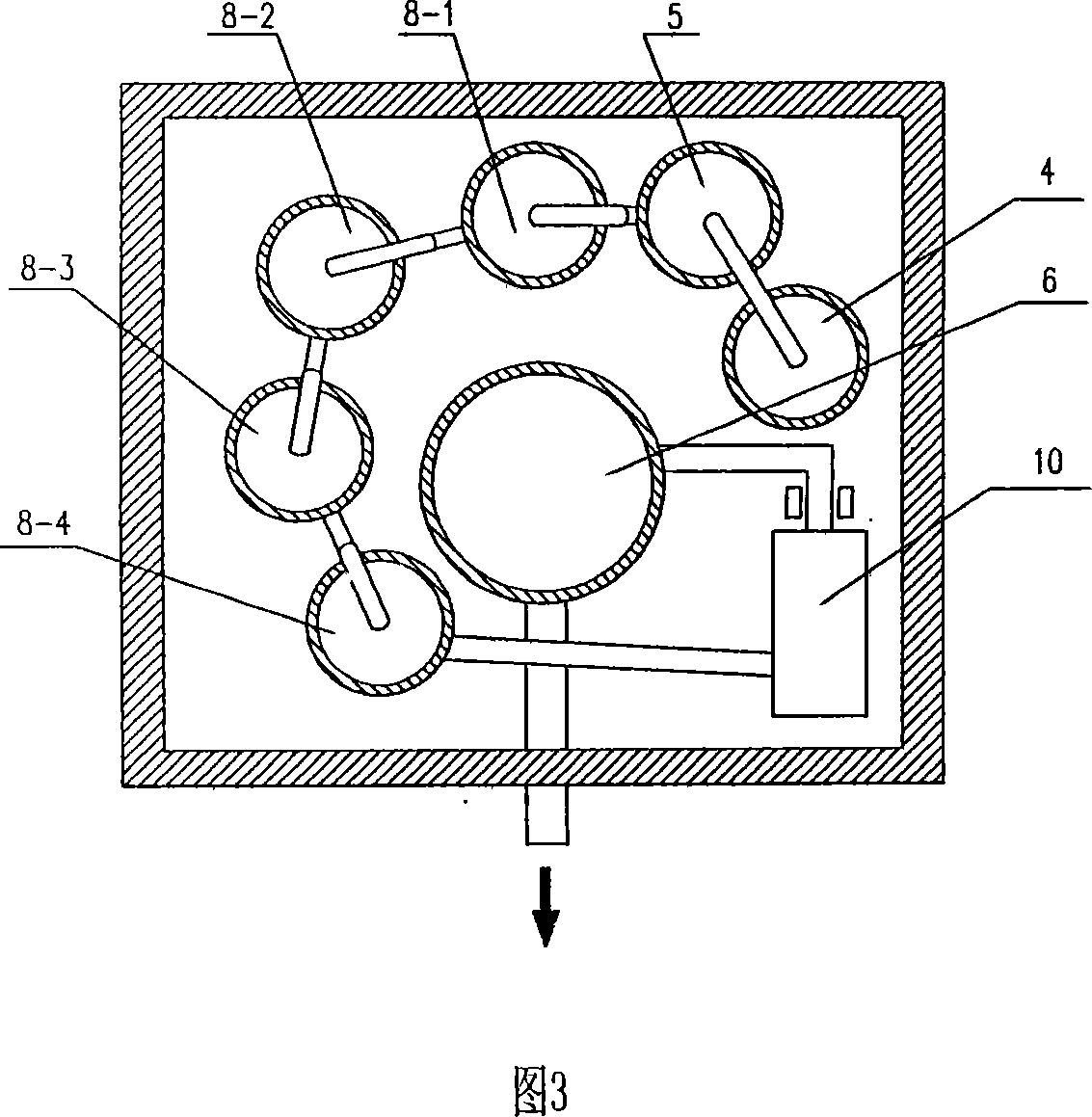

[0024] As shown in Figures 1 and 2, a water purification filter of the present invention includes a housing 1, a flocculation reaction tank 2, an agitator 3, an inclined tube settler 4, a ceramic filter element fine filter 5, a water storage tank 6, and a water outlet switch, The ceramic filter element fine filter 5 is made of refined diatomite and ceramic auxiliary materials and fired at high temperature. The flocculation reaction tank 2, the inclined tube settler 4 and the ceramic filter element fine filter 5 are connected together in sequence. The shape of the flocculation reaction tank 2 is Its upper part is a circle with 12 equal angles, and the bottom of the flocculation reaction tank 2 has a flocculation sediment discharge pipe with a pull switch, and when the switch of the discharge pipe is pulled, the silt and other dirt deposited in the flocculation reaction tank 2 will be discharged. row, the upper cover of the flocculation reaction barrel 2 is ABS transparent or opa...

Embodiment 2

[0026] The difference between this embodiment and the above-mentioned embodiment is that there is also a universal switching water valve at the rear of the machine. The universal switching water valve is installed between the fine filter of the ceramic filter element and the inclined tube settler. The water inlet is externally connected to tap water pipes, which can be adapted to tap water without flocculation reaction tank 2, inclined tube settler 4, fine filter only through ceramic filter element 5, quartz sand filter 8-1, activated carbon adsorber 8-2, medical stone water purifier 8-3, tourmaline water purifier 8-4, water flow sensor, water flow distribution plate 10, double-tube ultraviolet sterilizer, to obtain more pure water.

[0027] During use, take river water, lake water, or other surface water and pour it into the flocculation reaction barrel on the upper part of the machine, cover it, put a piece of flocculant through the injection hole, and turn the stirring handl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com