Local monitoring pressure sensitive cement base stress and strain sensor of concrete structure

A concrete structure and strain sensor technology, applied in the field of sensors, can solve the problems of single measurement parameters and low measurement accuracy, and achieve the effects of high embedding survival rate, high sensitivity and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

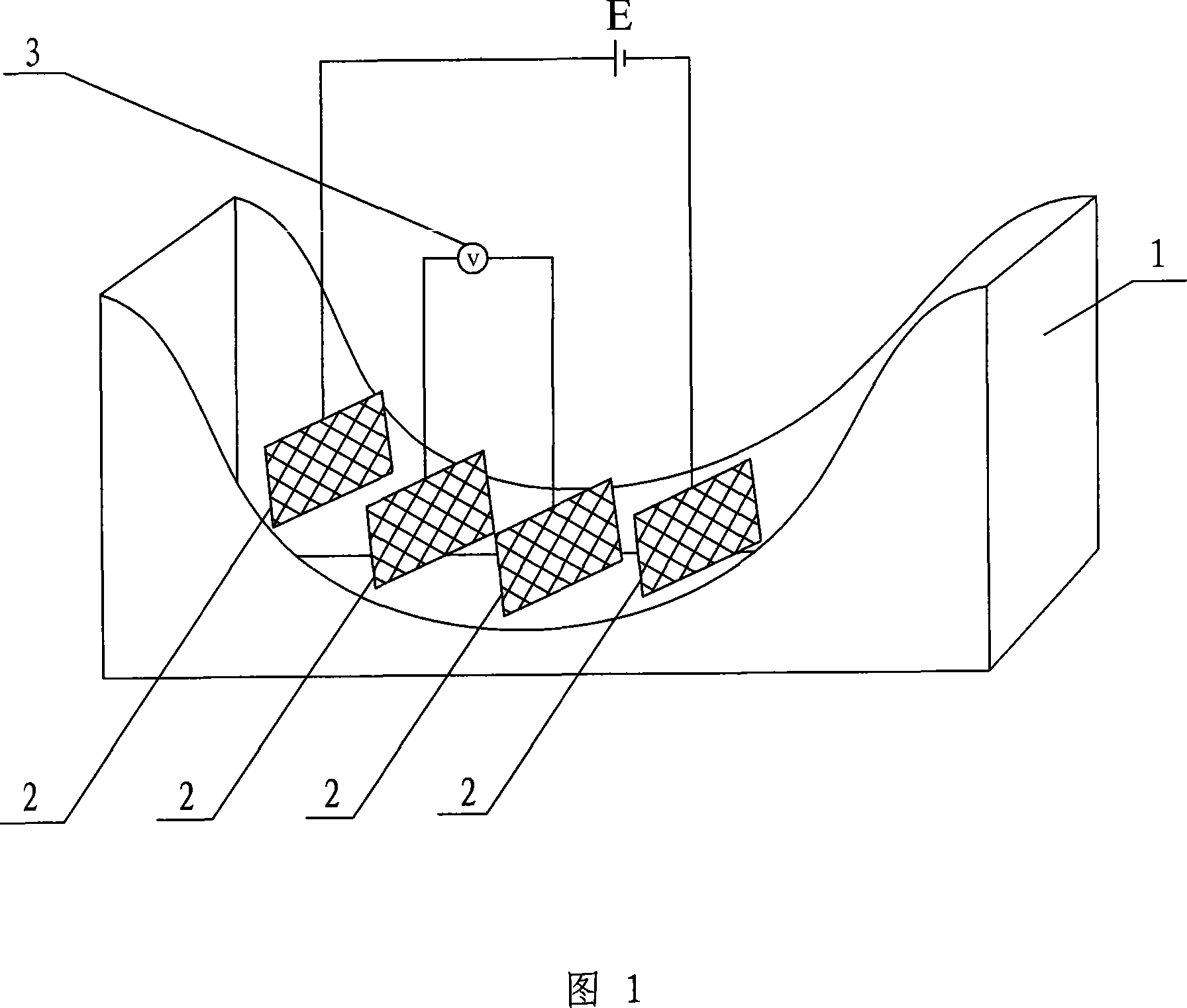

Image

Examples

specific Embodiment approach 2

[0007] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the conductive material is composed of chopped carbon fiber and carbon fiber powder, and the components of chopped carbon fiber and carbon fiber powder are in a weight ratio of 1-2:1-2.

specific Embodiment approach 3

[0008] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the conductive material is composed of carbon fiber powder and carbon black, and the weight ratio of carbon fiber powder and carbon black is 1-2:1-2.

specific Embodiment approach 4

[0009] Embodiment 4: The difference between this embodiment and Embodiment 1 is that the conductive material is composed of carbon black and chopped carbon fibers, and the components of carbon black and chopped carbon fibers are 1-2:1-2 by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com