La2O3-SnO2-Zn2SnO4 varistor-capacitor bifunctional ceramic material and preparation method thereof

A ceramic material and dual-function technology, applied in the field of ceramic materials, can solve the problems of complex process and high cost of pressure-sensitive-capacitance dual-function ceramics, and achieve good pressure-sensitive properties, easy to obtain or prepare, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A La 2 o 3 -SnO 2 -Zn 2 SnO 4 A method for preparing a pressure-sensitive-capacitance dual-function ceramic material, comprising the following steps:

[0025] Step 1: Zn 2 SnO 4 Preparation of powder

[0026] The analytically pure chemical reagent SnO 2 Mix with ZnO in a molar ratio of 1:2, and put it into a nylon ball mill tank, then add alcohol and ball mill for 12 hours at a speed of 120 rpm to obtain a slurry;

[0027] After the ball milled slurry is dried at 21°C~150°C, it is sent into a powder tablet press, and pressed into a disc with a diameter of 25-30mm under the condition of 80-120MPa. Put it into the muffle furnace, calcined at 1000°C for 2 hours, then cool it down to 20°C naturally, and crush the calcined disc to get Zn 2 SnO 4 Powder, spare;

[0028] Step 2: Weigh the analytically pure chemical reagent La respectively 2 o 3 , SnO 2 and the Zn prepared in step one 2 SnO 4 Dry-mix the powder, then put it into a nylon ball mill tank, and add a...

Embodiment 1

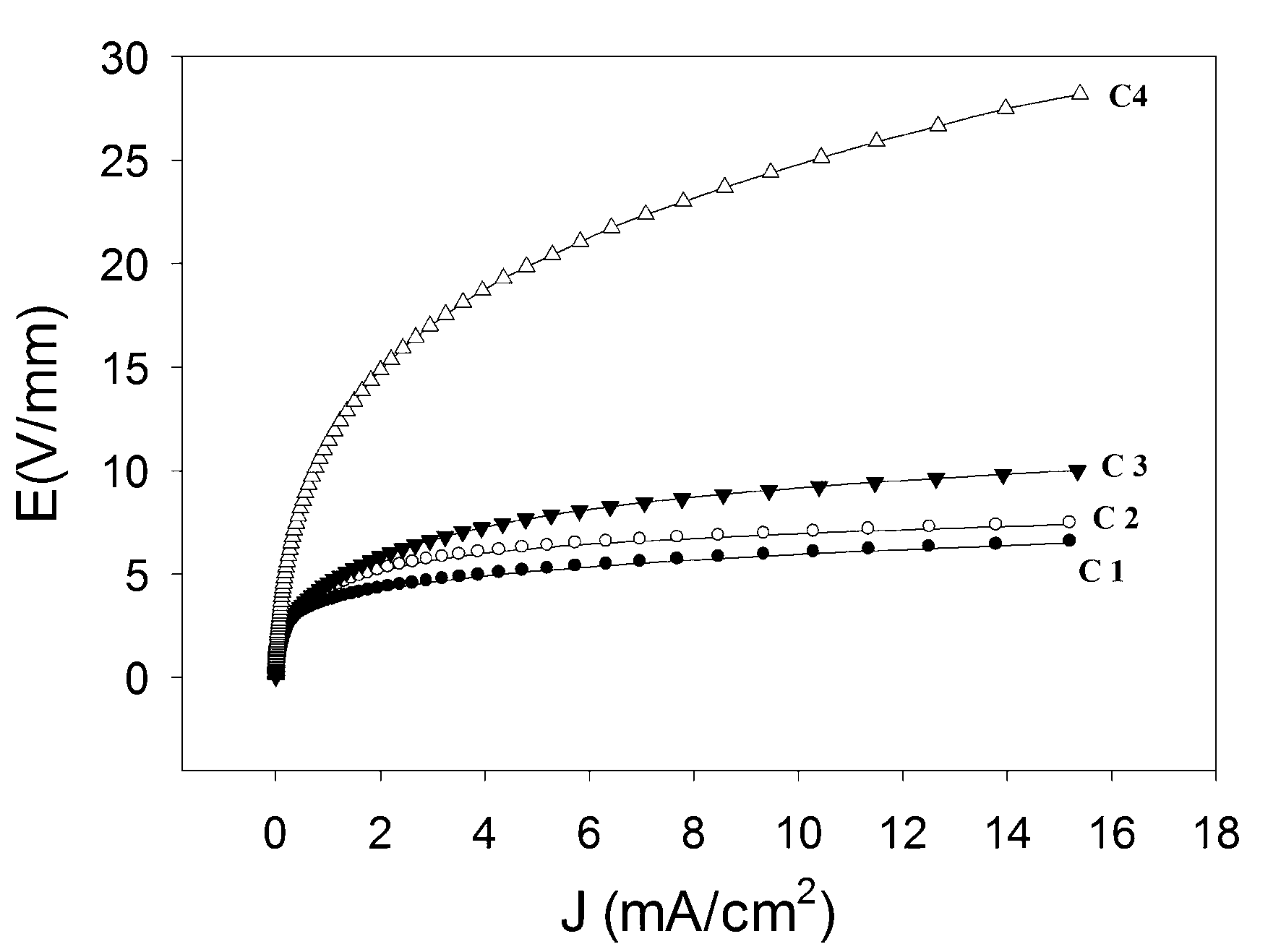

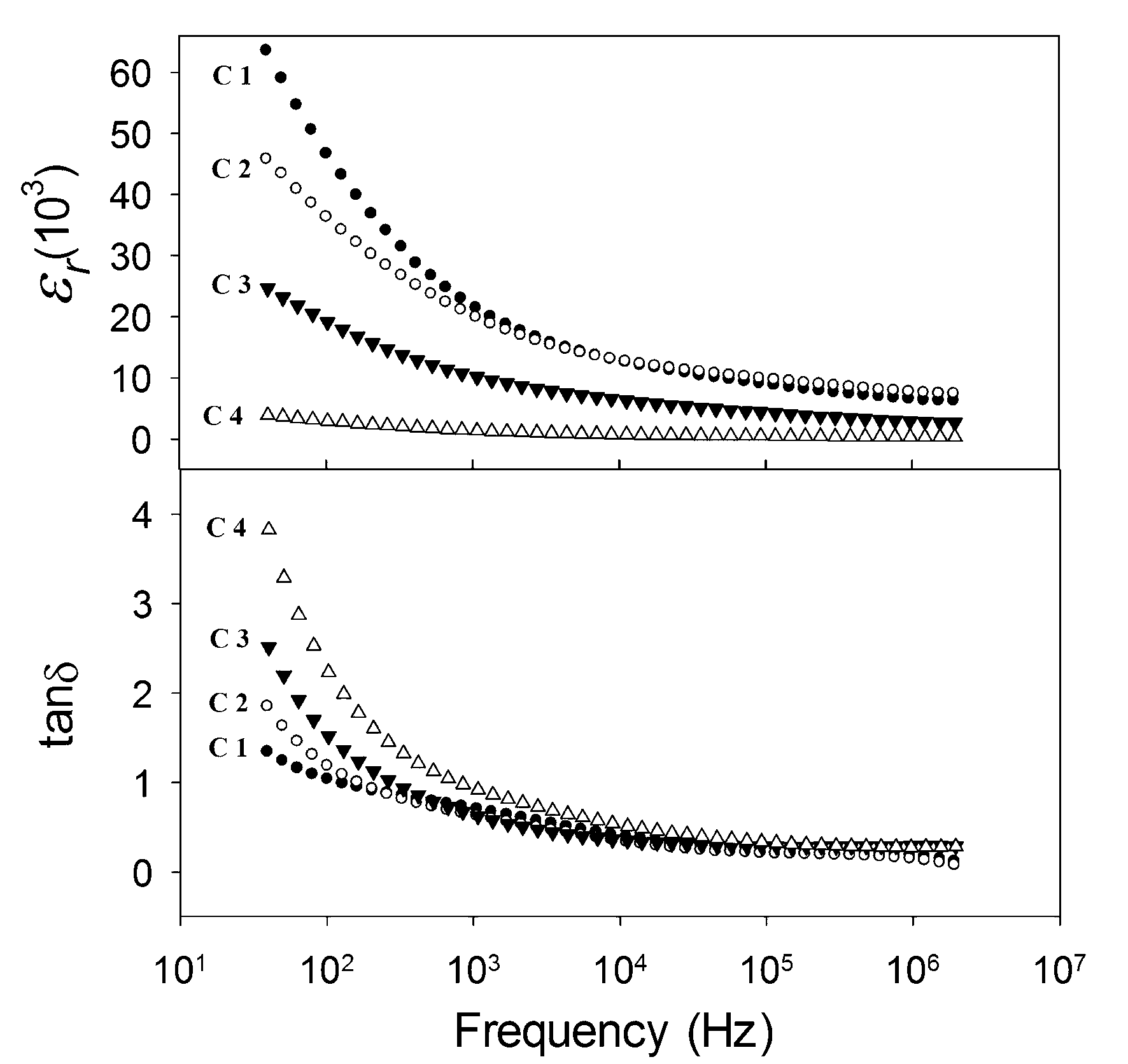

[0034] A La 2 o 3 -SnO 2 -Zn 2 SnO 4 Varistor-capacitance bifunctional ceramic material, the ceramic material is made of La 2 o 3 Powder, Zn 2 SnO 4 Powder and SnO 2 The powder is mixed and pressed, and sintered, and the molar ratio of each component is La 2 o 3 : SnO 2 : Zn 2 SnO 4 It is 0.1:85:15.

[0035] A La 2 o 3 -SnO 2 -Zn 2 SnO 4 Varistor-capacitance dual-function ceramic material, the preparation method of which is as follows:

[0036] Step 1: Zn 2 SnO 4 Preparation of powder

[0037] The analytically pure chemical reagent SnO 2 Mix with ZnO in a molar ratio of 1:2, and put it into a nylon ball mill tank, then add alcohol and ball mill for 12 hours at a speed of 120 rpm to obtain a slurry;

[0038] After the ball milled slurry is dried at 21°C~150°C, it is sent into a powder tablet press, and pressed into a disc with a diameter of 25mm under the condition of 80MPa, and the pressed disc is sent into a muffle In the furnace, calcined at 1000°C fo...

Embodiment 2

[0043] A La 2 o 3 -SnO 2 -Zn 2 SnO 4 Varistor-capacitance bifunctional ceramic material, the ceramic material is made of La 2 o 3 Powder, Zn 2 SnO 4 Powder and SnO 2 The powder is mixed and pressed, and sintered, and the molar ratio of each component is La 2 o 3 : SnO 2 : Zn 2 SnO 4 It is 0.4:85:15.

[0044] A La 2 o 3 -SnO 2 -Zn 2 SnO 4 Varistor-capacitance dual-function ceramic material, the preparation method of which is as follows:

[0045] Step 1: Zn 2 SnO 4 Preparation of powder

[0046] The analytically pure chemical reagent SnO 2 Mix with ZnO in a molar ratio of 1:2, and put it into a nylon ball mill tank, then add alcohol and ball mill for 12 hours at a speed of 120 rpm to obtain a slurry;

[0047] After the milled slurry is dried at 21°C~150°C, it is sent into a powder tablet press, and pressed into a disc with a diameter of 30mm under the condition of 100MPa, and then the prepared disc is sent to the horse In the furnace, calcined at 1000°C f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com