Water-retaining gel material and preparation method thereof

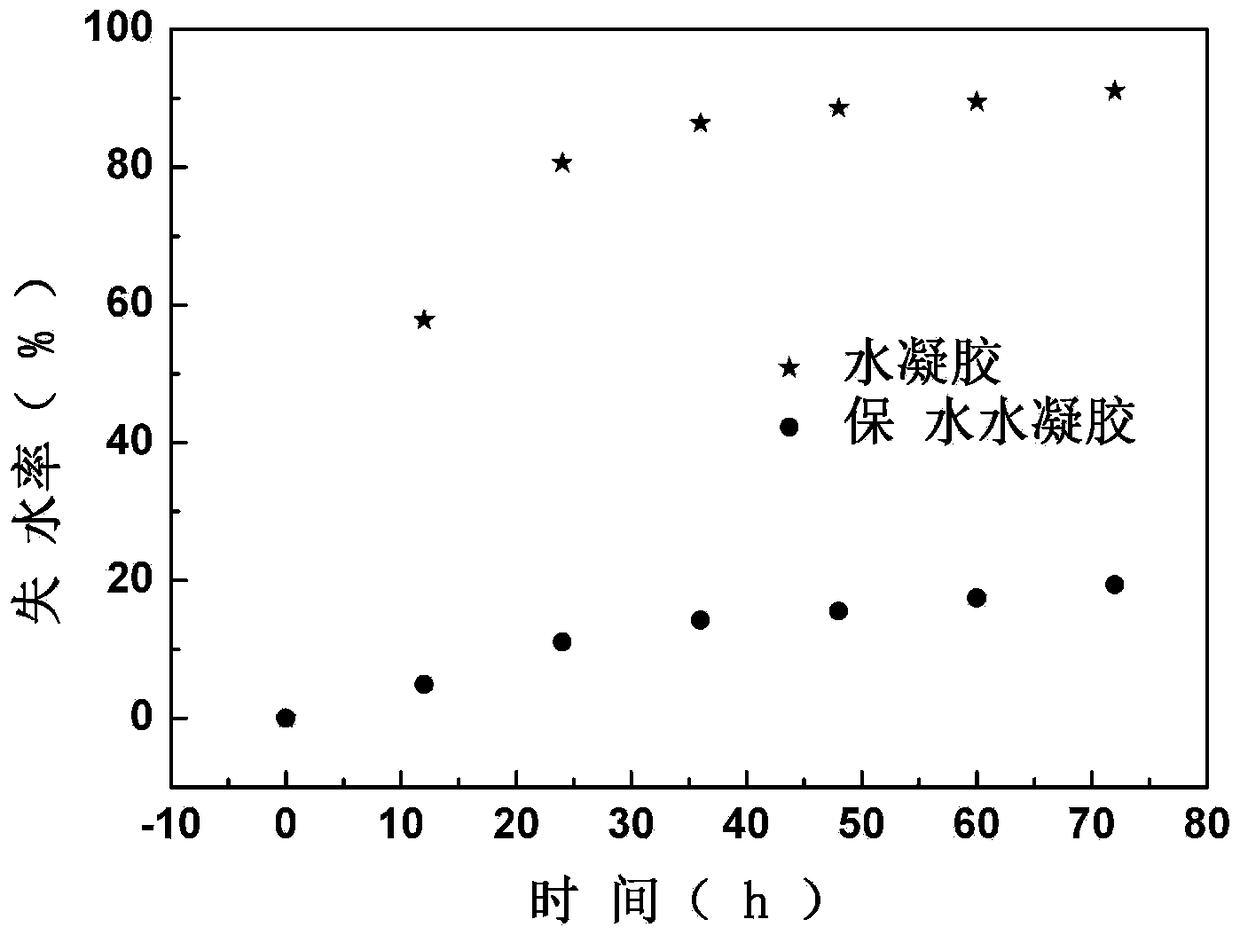

A technology of water-retaining gel and water-retaining layer, which is applied in the direction of chemical instruments and methods, rubber layered products, layered products, etc., can solve the problems of the decline of the conductivity and sensitivity of the ionic skin, and the easy loss of water in the ionic skin, so as to prevent The effect of water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation raw materials of the conductive layer include agar, polyvinyl alcohol, acrylic acid, persulfate, N,N-methylenebisacrylamide, inorganic metal salt and water, the agar, polyvinyl alcohol, acrylic acid, persulfate , N,N-methylenebisacrylamide, the mass ratio of inorganic metal salt and water is (0.3~0.6): (1.0~1.6): (3.0~6.0): (0.01~0.06): (0.01~0.05) : (0.3 to 0.5): (0.75 to 0.80).

[0036] The water-retaining gel material of the present invention comprises a first water-retaining layer and a second water-retaining layer, and the first water-retaining layer and the second water-retaining layer are polysiloxane elastomers. In the present invention, the polysiloxane elastomer is preferably polymethylphenylsiloxane, polyether polysiloxane or polydimethylsiloxane. In the present invention, the thicknesses of the first water retaining layer and the second water retaining layer are independently preferably 1 to 2 mm.

[0037] The water-retaining gel material o...

Embodiment 1

[0071] 1) First, mix 3 mL of polymethylphenylsiloxane and 0.3 mL of vinyltriamine, inject it into a petri dish, and bake it at 60°C to semi-dry to obtain a polymethylphenylsiloxane elastomer layer ;

[0072] 2) The elastomer surface was thoroughly cleaned with methanol and deionized water, and then the elastomer was fully soaked in BP solution (10 wt% ethanol solution) for 2 minutes at room temperature. After that, the elastomer was washed three times with methanol and completely dried with nitrogen to obtain a first water-retaining layer.

[0073] 3) Dissolve 0.3 g of agar and 1.0 g of polyvinyl alcohol in 20 mL of deionized water at 95°C, then add 3 g of acrylic acid to the reaction mixture, pass nitrogen into the mixture for deoxygenation for 10 min, and add 0.01 g of persulfuric acid Ammonium, 0.03g of N,N-methylenebisacrylamide, and 0.30g of iron salt, the resulting solution was injected into a mold equipped with an elastomer, kept at 60°C, and kept at a constant tempera...

Embodiment 2

[0078] 1) First, 3 mL of polyether polysiloxane and 0.3 mL of diaminocyclohexane were mixed, poured into a petri dish, and dried at 60° C. until semi-dry solidification to obtain a polyether polysiloxane elastomer.

[0079] 2) The elastomer surface was thoroughly cleaned with methanol and deionized water, and then the elastomer was fully soaked in BP solution (10 wt% ethanol solution) for 2 minutes at room temperature. After that, the elastomer was washed three times with methanol and completely dried with nitrogen to obtain a first water-retaining layer.

[0080] 3) Dissolve 0.4 g of agar and 1.1 g of polyvinyl alcohol in 21 mL of deionized water at 95°C, then add 3 g of acrylic acid to the reaction mixture, pass nitrogen into the mixture for deoxygenation for 10 min, and add 0.02 g of persulfuric acid Potassium, 0.01 g of N,N-methylenebisacrylamide, and 0.40 g of aluminum salt, the resulting solution was injected into a petri dish containing an elastomer, kept at 65°C, and k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com