Continuous emulsification method and emulsification apparatus therefor

A technology of emulsification equipment and screen, which is applied in the direction of chemical instruments and methods, mixing methods, dissolution, etc., can solve the problems of poor uniformity of dispersed phase droplets, unsatisfactory, complicated equipment, etc., and achieve good product stability and maintenance The effect of excellent performance and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

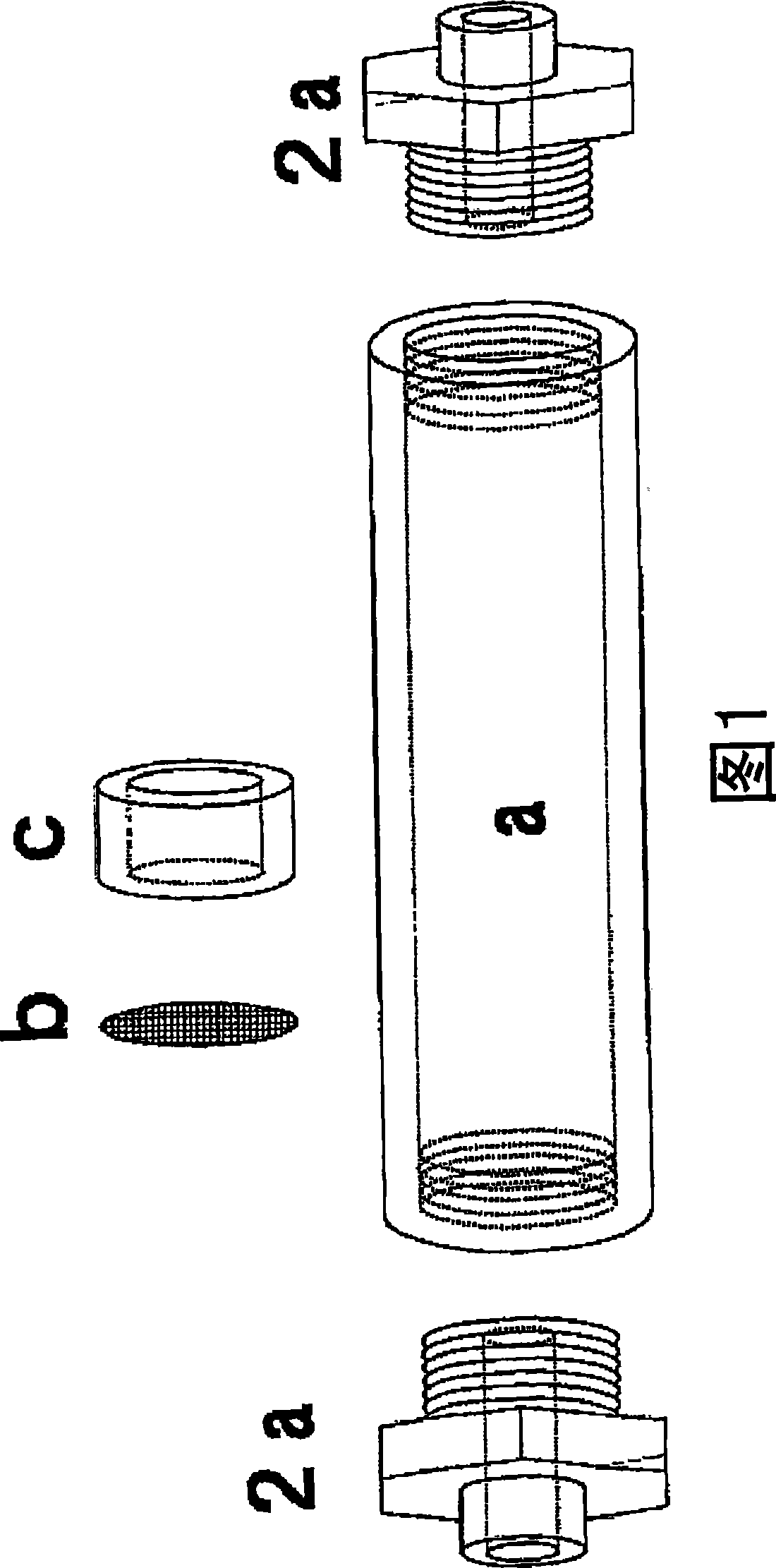

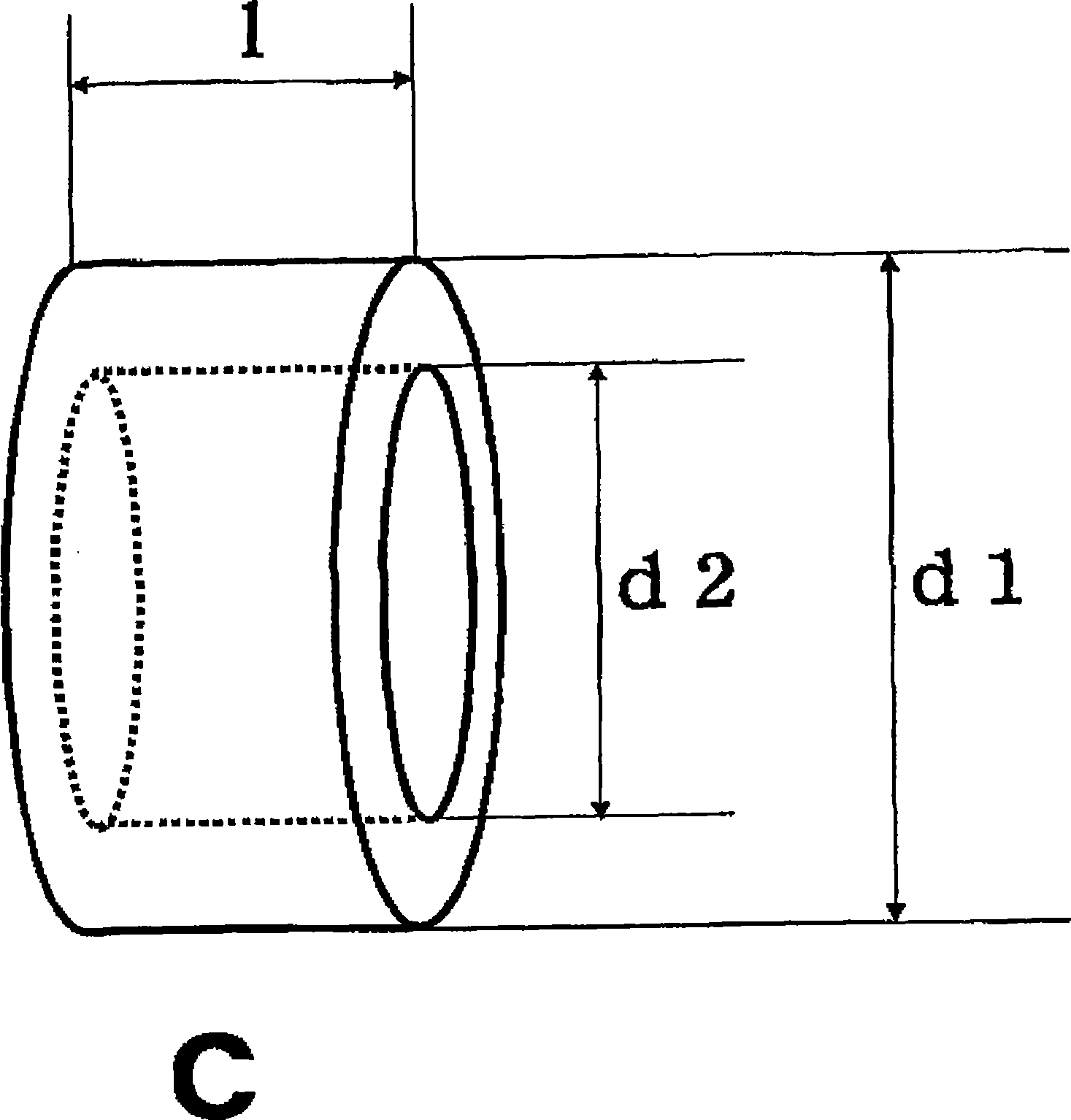

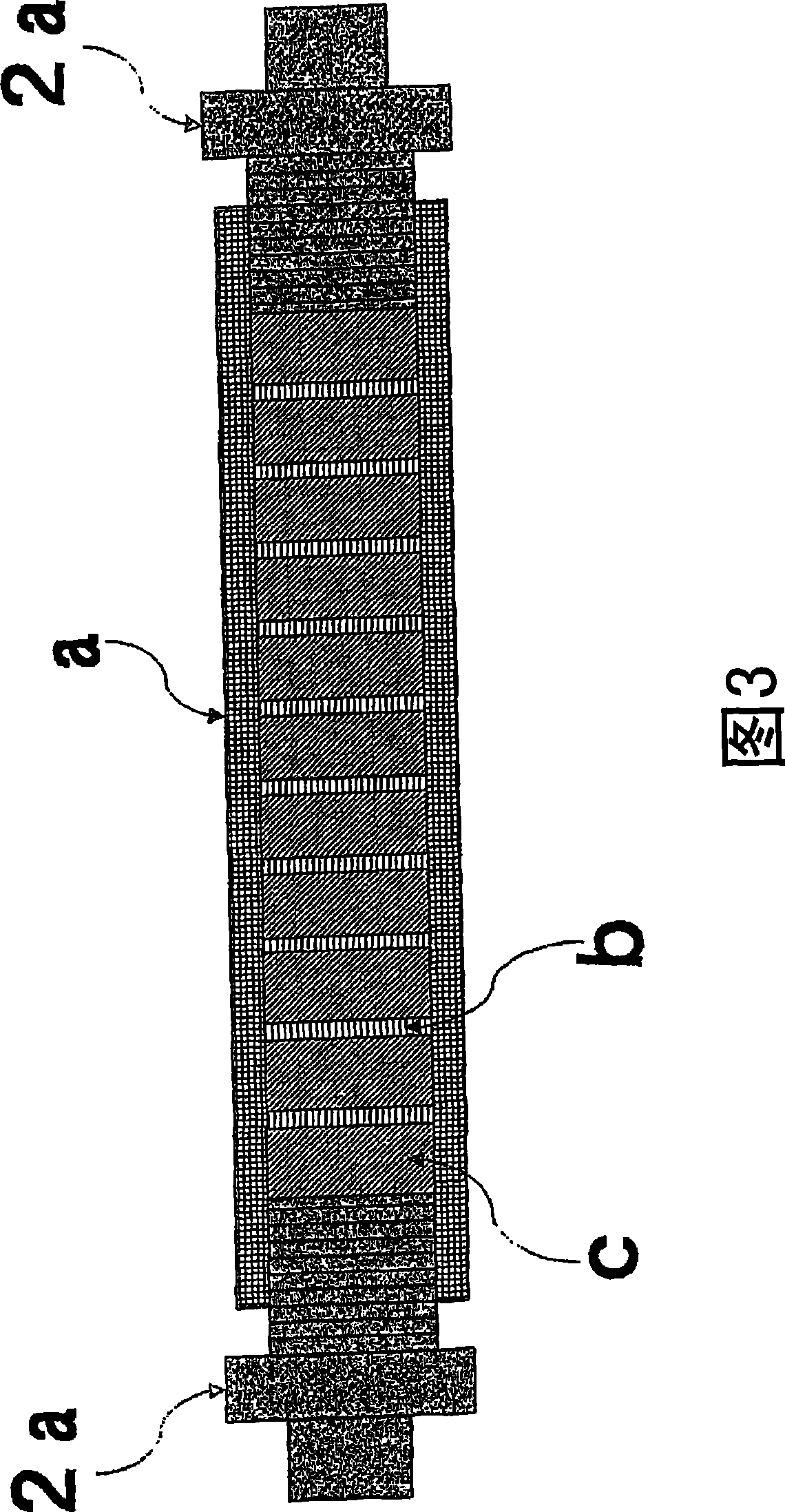

[0081] The emulsification apparatus was constructed by inserting 10 sets of units into a cylindrical housing with an inner diameter of 20 mm, each unit consisting of a wire mesh made of a 1400-mesh main wire mesh and a partition having a length of 10 mm and an inner diameter of 15 mm. The length of the housing is about 120mm.

[0082] As the raw material to be emulsified, a hydrocarbon-based solution (Nisseki Naphtesol (200 grade)) (density: 813kg / m 3 (15°C), distillation boiling point range: 201-217°C, supplied by Nippon Oil Company) mainly includes naphthenic (cycloalkane)-based hydrocarbon mixture and dispersant aqueous solution (1% quality PVA205, supplied by Kuraray Co., Ltd.), And the emulsification was carried out by introducing the raw materials into the emulsification equipment through independent plunger pumps at flow rates of 100 ml / min and 200 ml / min respectively, thereby obtaining an O / W emulsion. The volume average diameter of the dispersed phase droplets of the...

example 2

[0087] An emulsion was prepared by the same operation as in Example 1 except that the number of units to be inserted into the housing was 40. The dispersed phase had a volume average particle size of 18 μm and a CV value of 24%.

example 3

[0089] An emulsion was prepared by the same operation as in Example 1, except that a 250-mesh wire mesh was used as the main wire mesh. The dispersed phase had a volume average particle size of 55 μm and a CV value of 25%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com