Novel electric driving control system and method for vehicle air conditioner compressor

A vehicle air conditioner and control system technology, applied in the direction of single motor speed/torque control, electric vehicle charging technology, motor, etc., to achieve smooth start, improve motor operating efficiency, and solve the effect of motor operation control problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

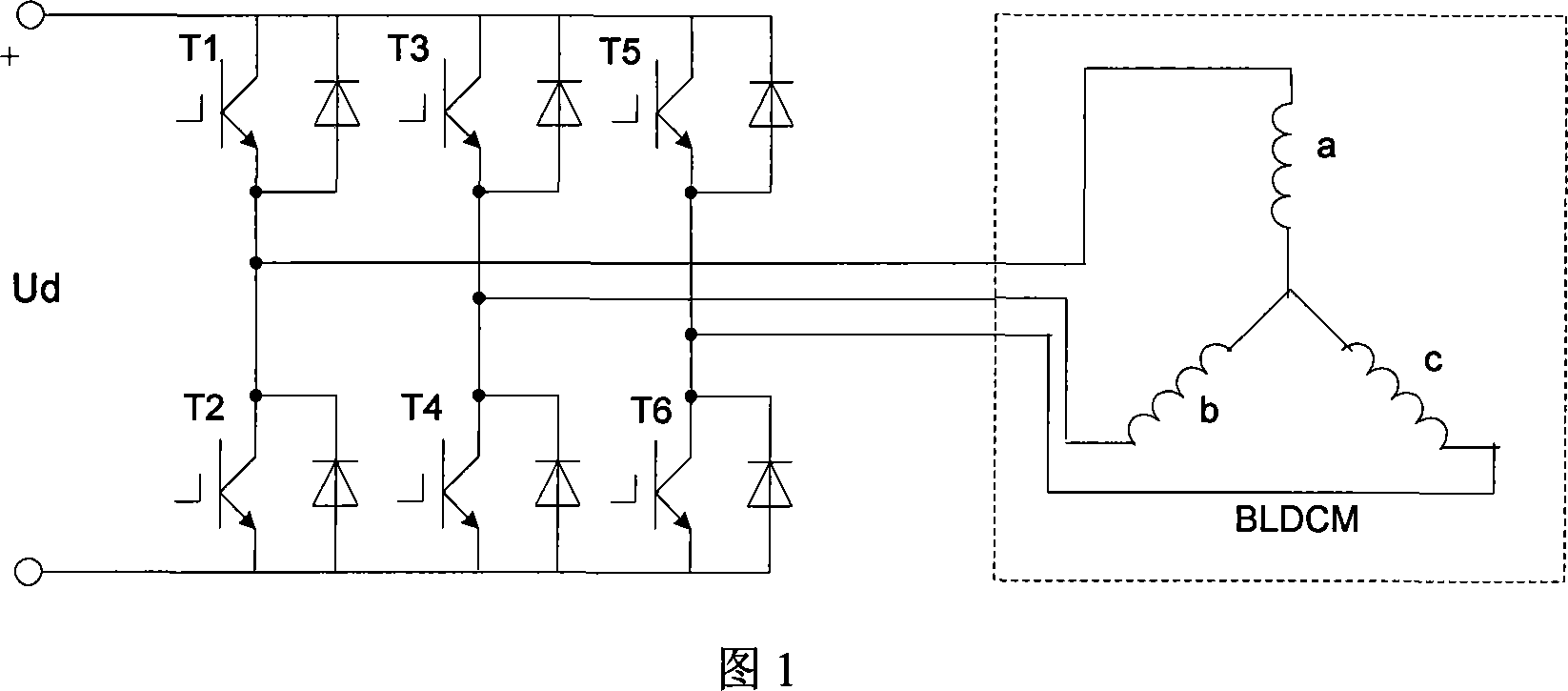

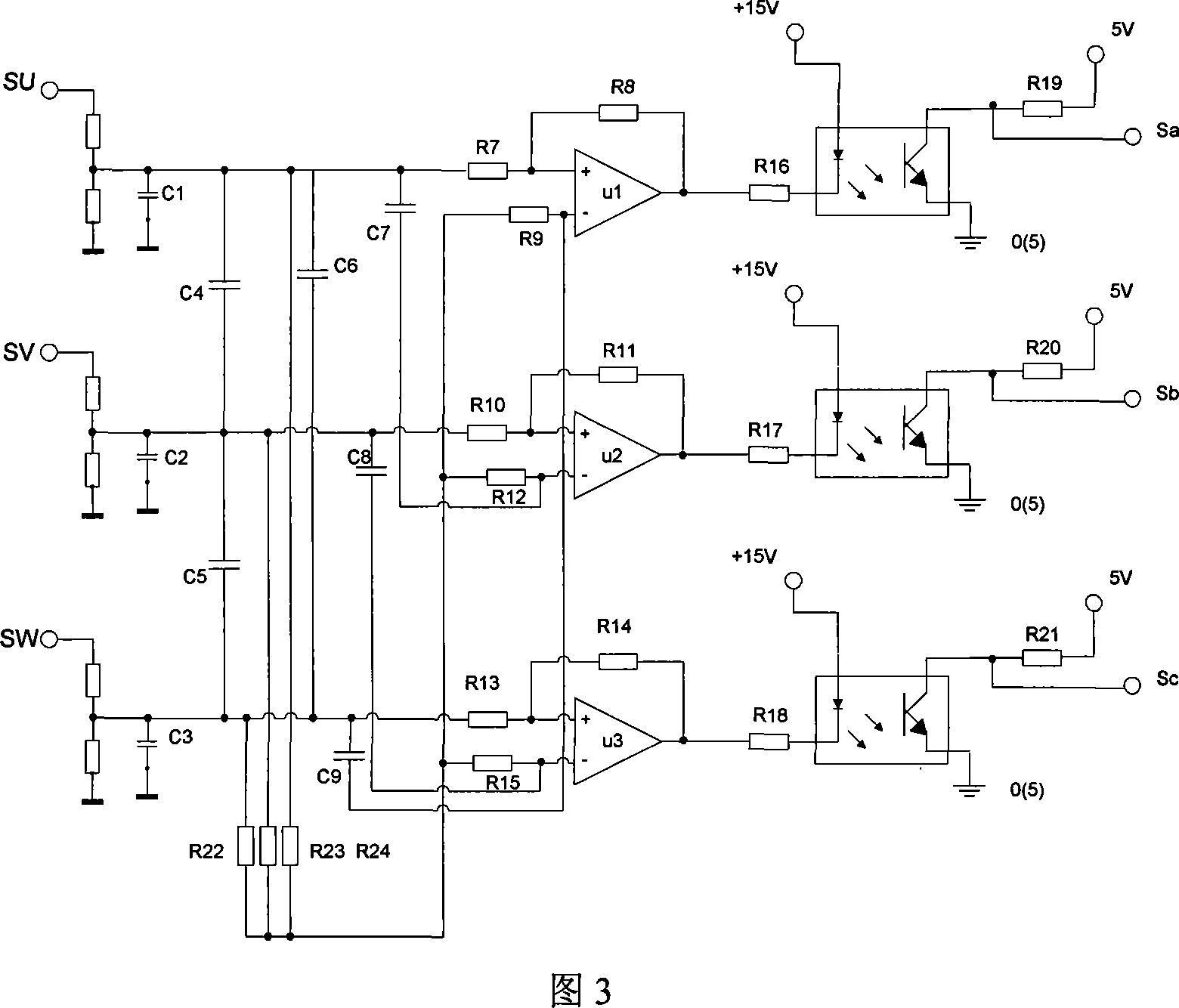

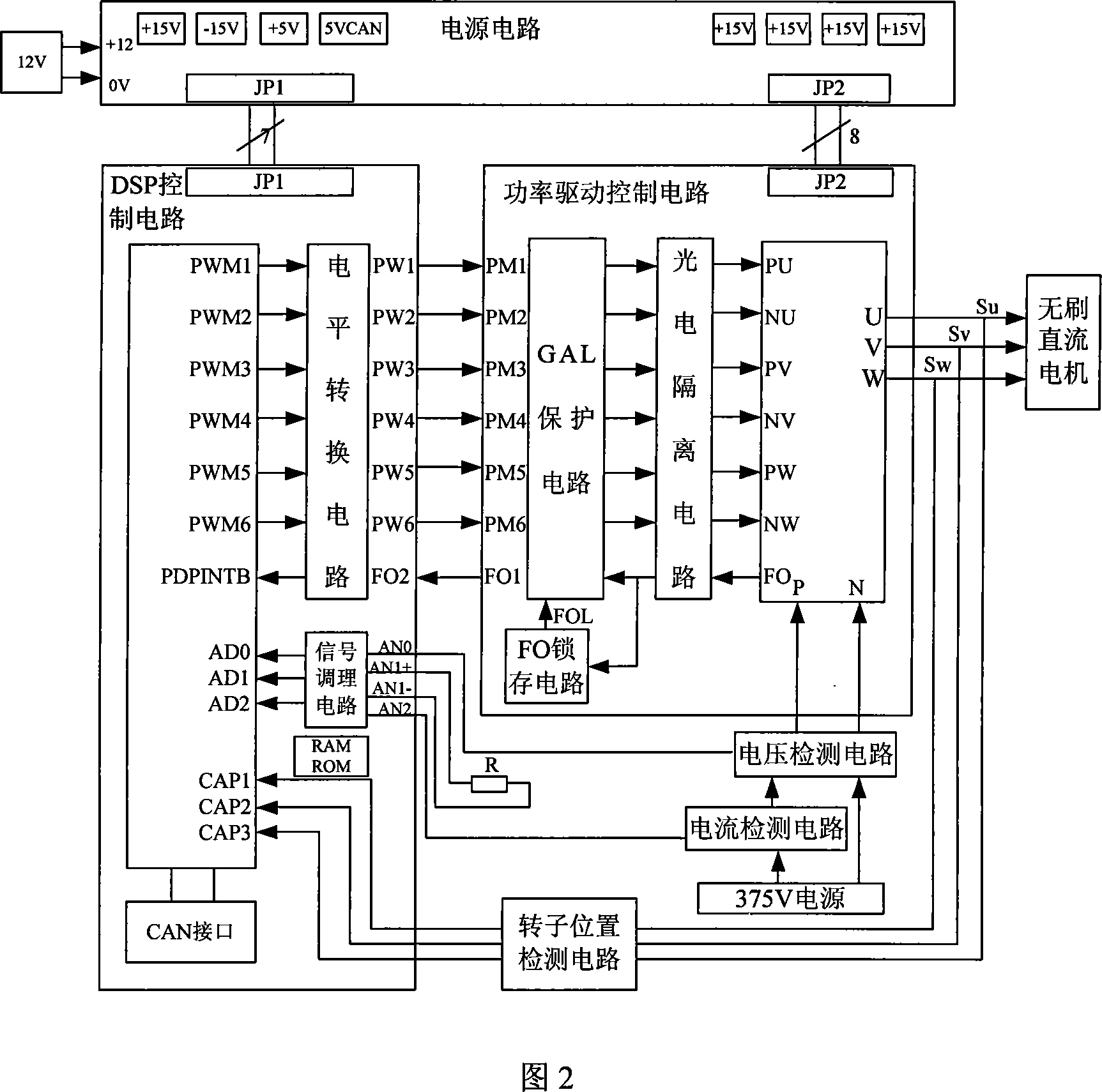

[0044] A new type of electric drive control system for vehicle air-conditioning compressors, using a positionless brushless DC motor, the general block diagram is shown in Figure 2, and the specific connections are as follows:

[0045] 1) The FO1 port of the power drive control circuit is connected to the PDPINTB port of the DSP control circuit to provide protection signals such as overcurrent, overheating and short circuit of the module;

[0046] 2) The 375V power supply is connected to the P and N ports of the power drive control circuit to supply power to it;

[0047] 3) The four-way 15V power supply port J2 of the power supply circuit is connected to the power supply port J2 of the power drive control circuit to supply power to it;

[0048] 4) The power supply port J1 of the power supply circuit is connected with the power supply port J1 of the DSP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com