Pressure-sensitive adhesive tape or sheet, and process for producing pressure-sensitive adhesive tape or sheet

A technology of adhesive tapes and adhesives, applied in bandages, adhesive dressings, medical science, etc., can solve problems such as hardening and insufficient suppression of void ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

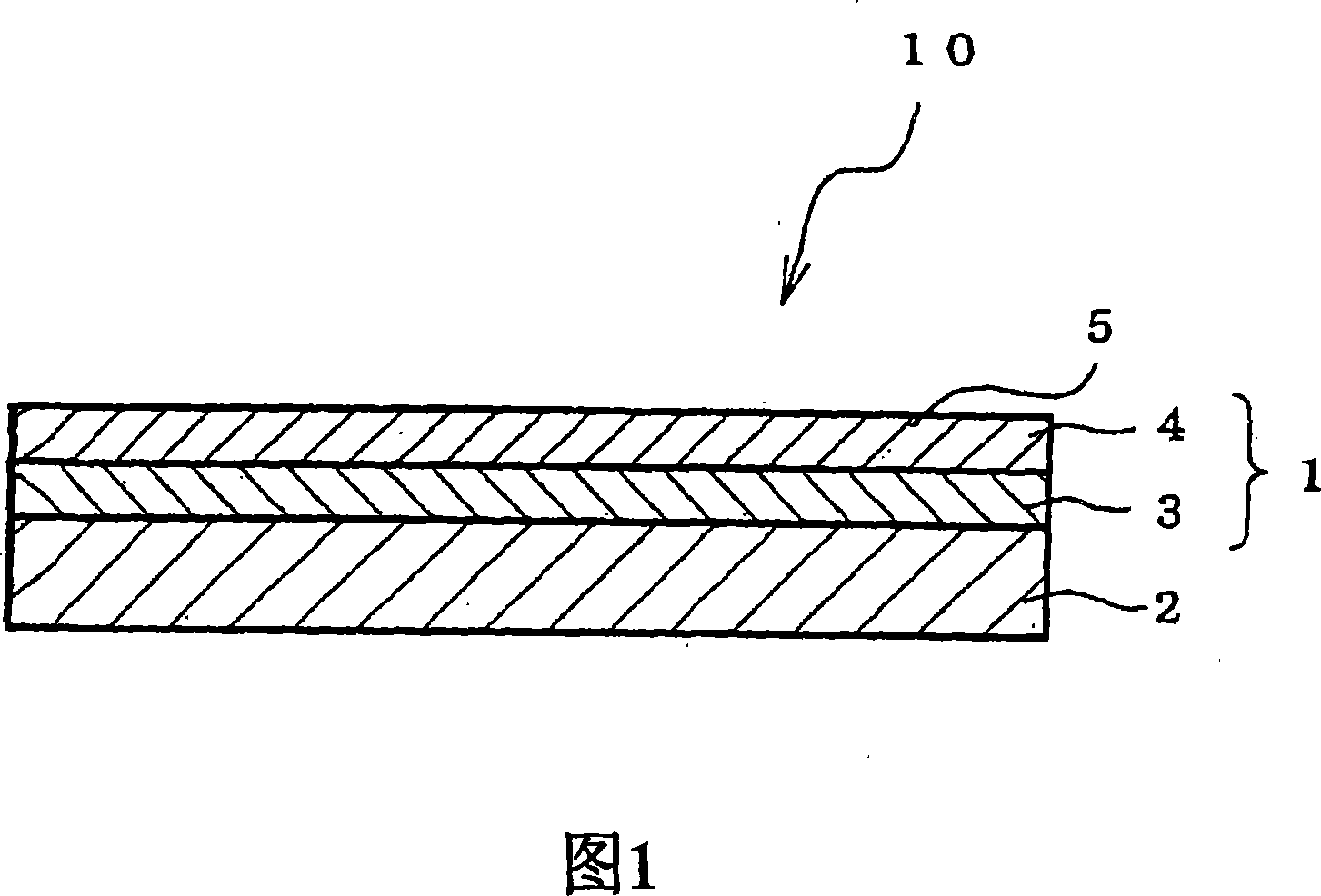

[0082] Fig. 1 is a sectional view of a pressure-sensitive adhesive tape or sheet (hereinafter simply referred to as "pressure-sensitive adhesive tape") in one embodiment of the present invention. The pressure-sensitive adhesive tape 10 of the present invention includes a support 1 and a pressure-sensitive adhesive layer 2 arranged on one face of the support 1, and the support 1 is treated with a filler. The support body 1 is constituted by a laminate of a two-layer structure, including a first base material 3 and a second base material 4, and a pressure-sensitive adhesive layer 2 is arranged on the first base material 3 so that the second base material 4 acts as a The outermost layer 5 on the support side.

[0083] The first substrate includes a non-woven fabric produced by a melt-blown method. By using the melt-blown non-woven fabric, hardening can be prevented due to its good air permeability, and the filling process can be easily performed due to the high density of the me...

no. 2 example

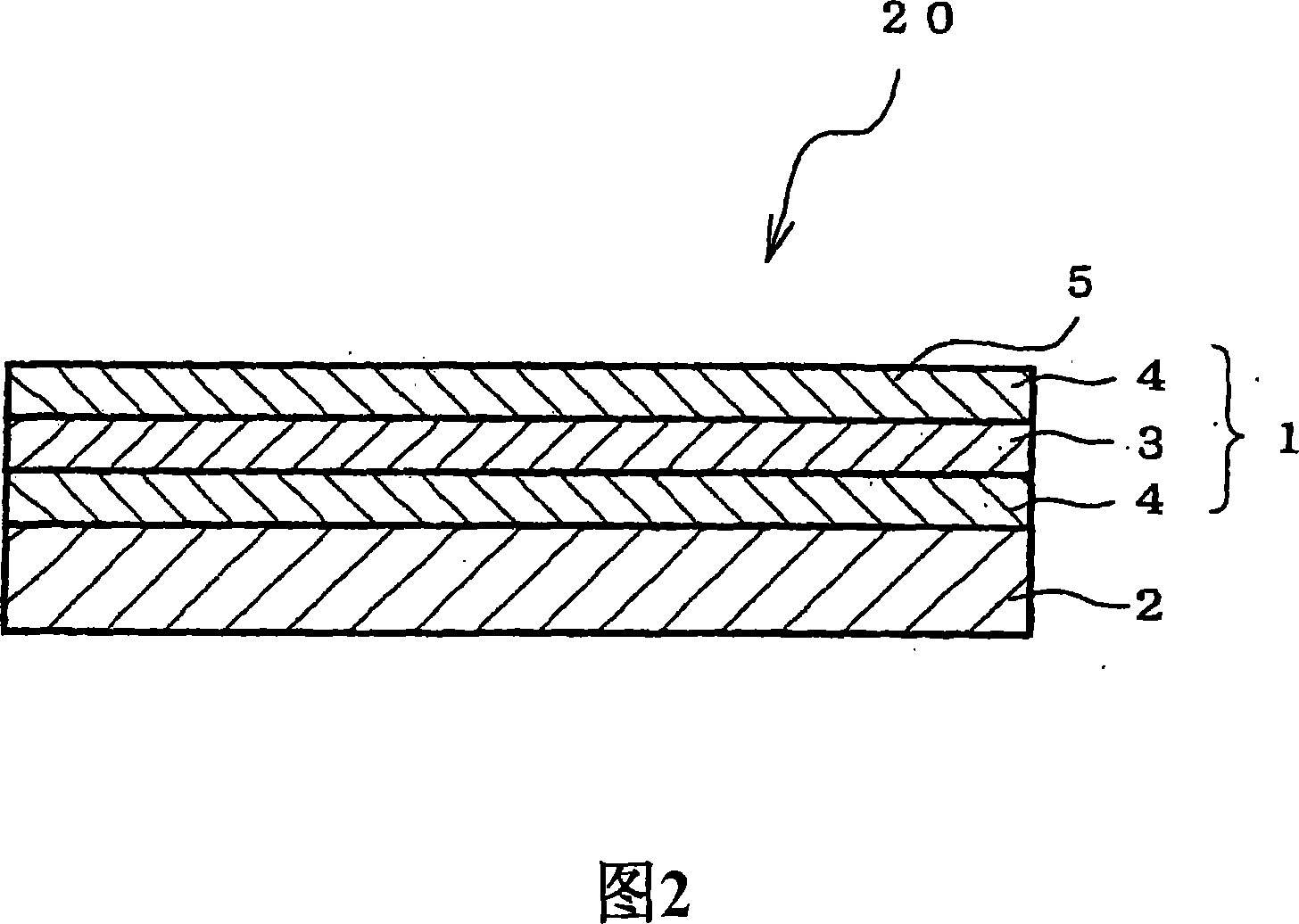

[0099] Fig. 2 is a sectional view showing an adhesive tape according to another embodiment of the present invention. The pressure-sensitive adhesive tape 20 includes a support body 1 and a pressure-sensitive adhesive layer 2 arranged on one face of the support body 1 . The support 1 consists of a laminate comprising a first substrate 3 and a second substrate 4 arranged on both sides of the first substrate 3 and which is designed as the support side The outermost layer 5. The pressure-sensitive adhesive tape in the second embodiment is different from the pressure-sensitive adhesive tape including the laminated body of the two-layer structure in the first embodiment in that the support body in the second embodiment has a three-layer structure. The two base materials constituting the support may be the same or different. The compositions of the first base material and the second base material and the pressure-sensitive adhesive layer are the same as those described in the first...

Embodiment 1

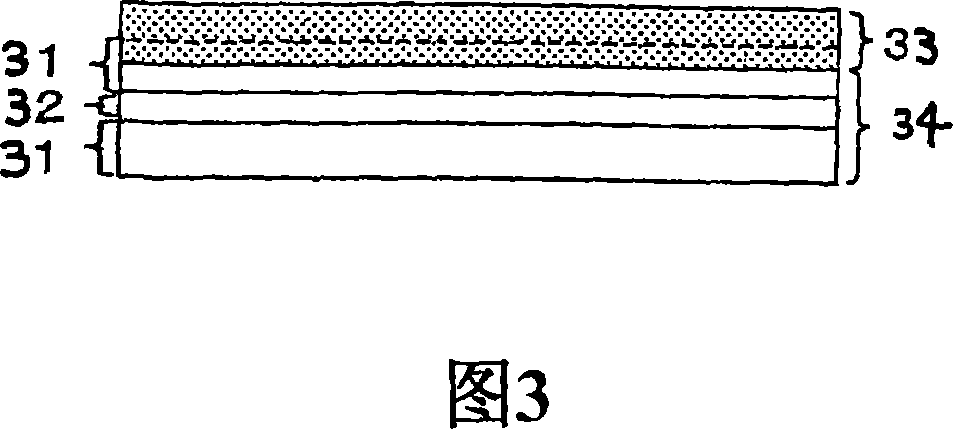

[0157] Laminated on both sides of a non-woven fabric (made of polyester, thickness: 25 μm, fiber diameter: 1.8 μm) produced by a meltblown method with a bulk density of 0.21 g / cm produced by a spunbond method 3 After the non-woven fabric (made of polyester, thickness: 80μm, fiber diameter: 14μm), apply 25g / m 2 The filler is used for filling treatment, so as to obtain the support body after filling treatment. Boncoat R3360 (trade name, manufactured by Dainippon Ink and Chemicals Inc.) was used as the filler. The air permeability of the obtained support was 12 seconds / 100 cc. Subsequently, the pressure-sensitive adhesive layer obtained above was transferred onto the filling-treated support to obtain a pressure-sensitive adhesive sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com