Method for preparing titanium dioxide/13X molecular sieves compound material for treating dyestuff waste water

A composite material and dye wastewater technology, which is applied in the field of preparation of TiO2/13X molecular sieve composite materials, can solve the problems of secondary pollution adsorbent and coagulant regeneration, which cannot be reasonably solved, the utilization rate of sunlight is not high, and the photo-generated air is empty. Problems such as easy compounding of holes, to achieve the effects of abundant micropores, improved degradation efficiency, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

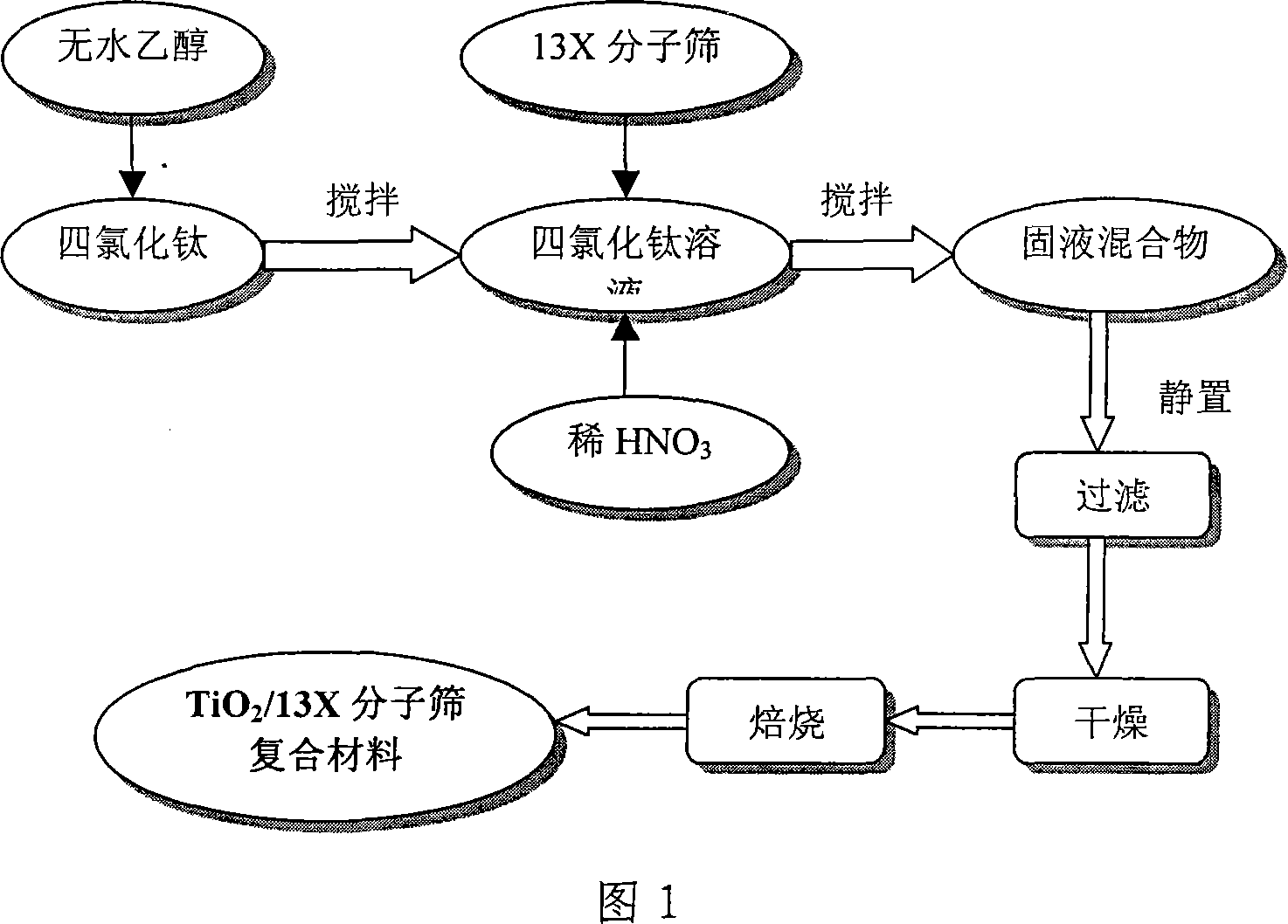

[0023] 1. Measure 8ml of titanium tetrachloride solution in a beaker filled with 40ml of absolute ethanol to make a titanium tetrachloride / absolute ethanol solution, and stir vigorously at a constant speed.

[0024] 2. Weigh 10g of 13X molecular sieve with a particle size of 100 mesh, add it into a beaker filled with titanium tetrachloride solution, and stir vigorously at a constant speed for 3 hours.

[0025] 3. Then add dilute HNO dropwise into the beaker 3 Solution 10ml, stir for 2-3min, slowly add about 3ml of deionized water, stop stirring.

[0026] 4. After airtight aging at room temperature for 48 hours, the vacuum pump is used for suction filtration, and the filtrate is washed several times with absolute ethanol and deionized water.

[0027]5. Put the filtered sample into a constant temperature blast drying oven, adjust the temperature to 110°C, and dry for 3 hours.

[0028] 6. Put the dried sample into a muffle furnace and bake it at 200°C for 4h.

[0029] 7. Get T...

Embodiment 2

[0031] 1. Measure 6ml of titanium tetrachloride solution in a beaker filled with 35ml of absolute ethanol to make a titanium tetrachloride / absolute ethanol solution, and stir vigorously at a constant speed.

[0032] 2. Weigh 10g of 13X molecular sieve with a particle size of about 100 mesh, add it into a beaker filled with titanium tetrachloride solution, and stir vigorously at a constant speed for 2 hours.

[0033] 3. Then add dilute HNO dropwise into the beaker 3 Solution 5ml, stir for 2-3min, slowly add about 2ml of deionized water, stop stirring.

[0034] 4. After airtight aging at room temperature for 40 hours, the vacuum pump is used for suction filtration, and the filtrate is washed several times with absolute ethanol and deionized water.

[0035] 5. Put the filtered sample into a constant temperature blast drying oven, adjust the temperature to 110°C, and dry for 2 hours.

[0036] 6. Put the dried sample into a muffle furnace and bake it at 200°C for 4h.

[0037] 7....

Embodiment 3

[0039] 1. Measure 10ml of titanium tetrachloride solution in a beaker filled with 45ml of absolute ethanol to make a titanium tetrachloride / absolute ethanol solution, and stir vigorously at a constant speed.

[0040] 2. Weigh 10 g of 13X molecular sieve with a particle size of 80 mesh, add it to a beaker containing a titanium tetrachloride solution, and stir vigorously at a constant speed for 3 hours.

[0041] 3. Then add dilute HNO dropwise into the beaker 3 Solution 10ml, stir for 2-3min, slowly add about 5ml of deionized water, stop stirring.

[0042] 4. After airtight aging at room temperature for 48 hours, the vacuum pump is used for suction filtration, and the filtrate is washed several times with absolute ethanol and deionized water.

[0043] 5. Put the filtered sample into a constant temperature blast drying oven, adjust the temperature to 110°C, and dry for 3 hours.

[0044] 6. Put the dried sample into a muffle furnace and bake it at 200°C for 4h.

[0045] 7. Get ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com