Beam splitting type laser roughing modulation device

A laser texturing and spectroscopic technology, applied in laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of complex shape of chopper disc, long focusing distance, spot size and position can not be adjusted, etc., to achieve a reasonable focus spot and energy density, high wear resistance, effective preheat quenching and texturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

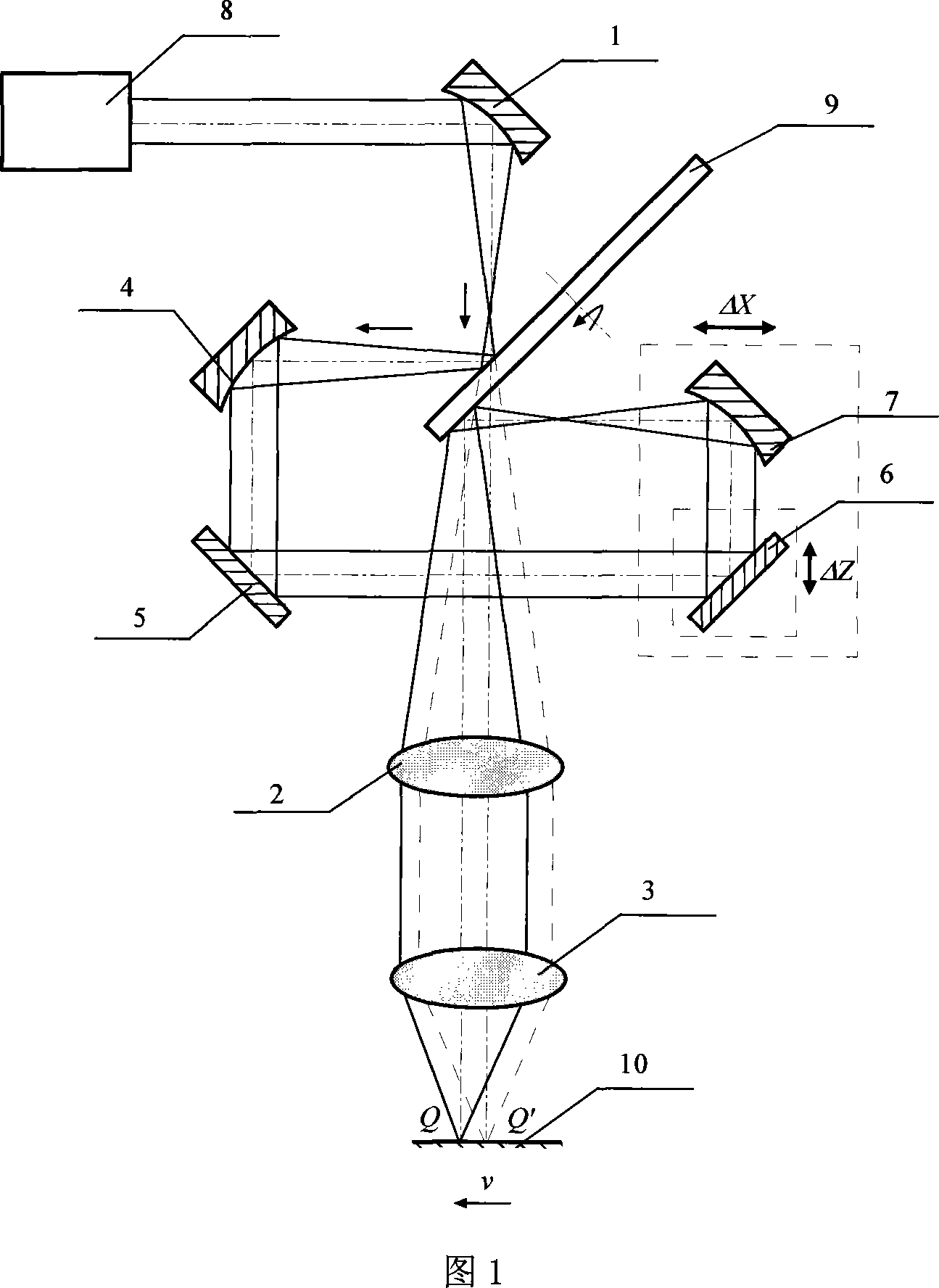

[0014] The embodiments of the present invention will be described in detail below with reference to the drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation modes and specific operation procedures are given, but the protection scope of the present invention is not limited to the following Mentioned examples.

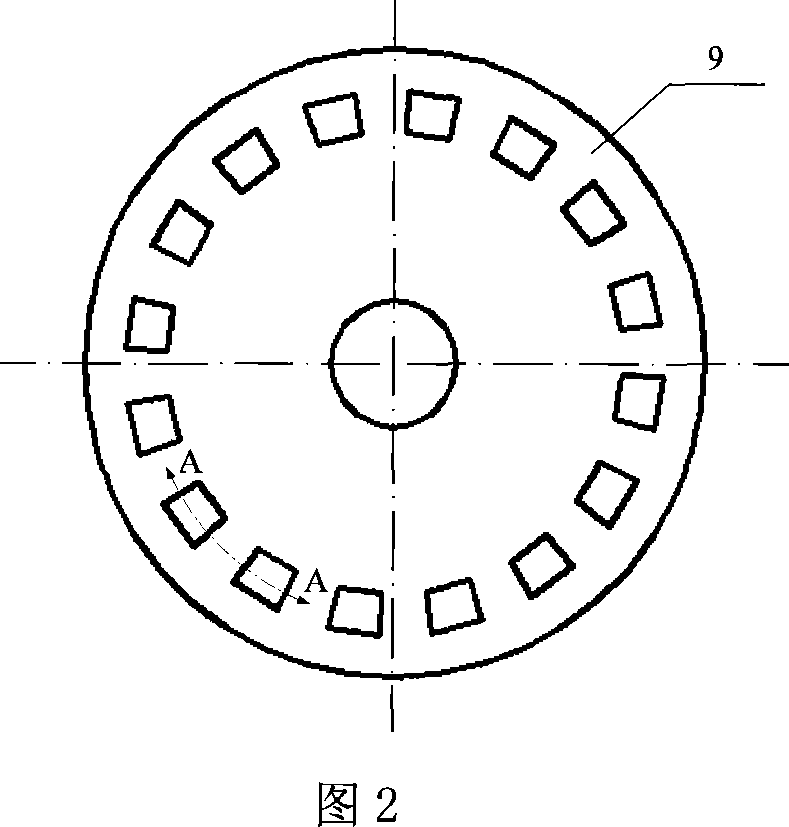

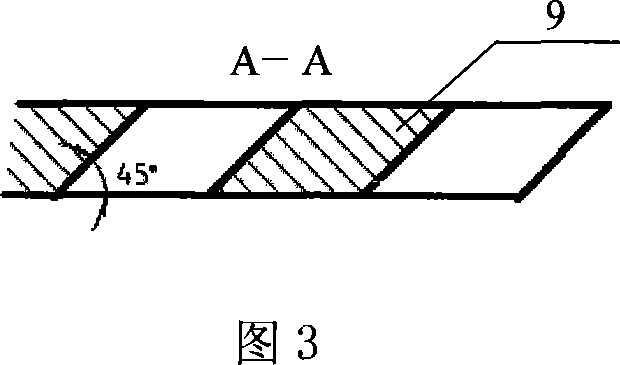

[0015] In order to obtain a higher texturing power density and to keep the focusing lens away from the workpiece to be processed, a beam expander telescope can be added to the light guide system of the laser processing system to reduce the divergence angle of the laser beam, and then focus again. The beam waist position (focus position) of the beam is transformed into the allowable range for processing, thereby increasing the processing range and effective focal depth of the laser beam, and obtaining a smaller focal spot diameter. In order to turn continuous light into pulsed light, a mechanic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com