Portable self-heating bag

A self-heating and heating bag technology, applied in the field of packaging bags, can solve the problems of inconvenient carrying, high manufacturing cost, inconvenient opening, etc., and achieve the effects of high temperature, fast heat generation, and convenient carrying and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

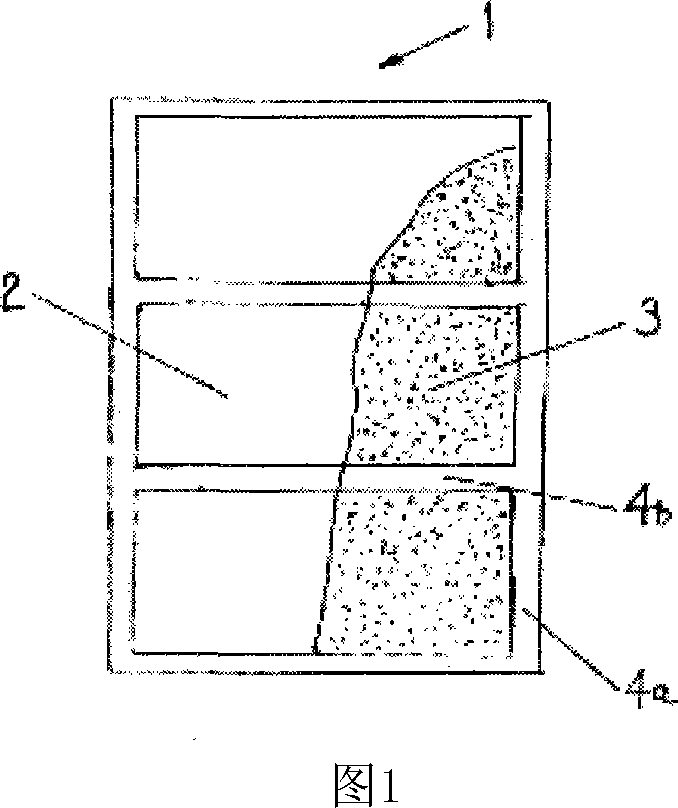

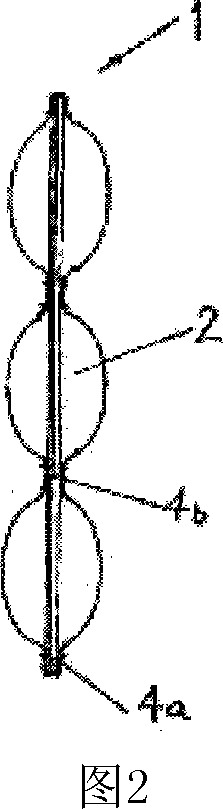

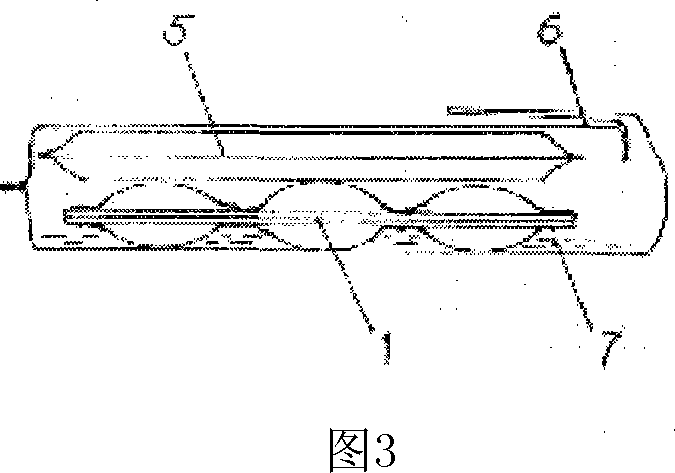

[0010] The heating bag 1 shown in Fig. 1, 2 is made of non-woven bag 2 and aluminum water type heating agent 3. The non-woven bag 2 can be a double-layer polyester hot-rolled non-woven fabric / polyethylene powder composite material through hydrophilic treatment. It can also be a composite material of hydrophilic treated polyester hot-rolled non-woven fabric / polyethylene powder / polypropylene hot-rolled non-woven fabric. Aluminum water type heat agent 3 is a mixture of industrial aluminum powder and alkaline materials, the particle size is in the range of 40 mesh to 200 mesh, usually packed in compartments. The bag edge 4a and the grid crossing 4b can be heat-sealed by low-frequency heat-sealing or ultrasonic heat-sealing. In order to prevent the bag edge 4a from opening, the four sides can also be reinforced by sewing. The storage of the heating bag 1 should be packed into the bagging 6 for moisture-proof sealing. When heating, as shown in FIG. 3 , the preheated packaged food...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com