Heat pipe and its combining method with heat-conductive base

A heat pipe and bottom plate technology, which is applied in the field of combination of heat pipe and heat conduction base, can solve the problems of affecting heat transfer efficiency, tightness, insufficient tightness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical content and detailed description of the present invention are now described as follows in conjunction with the drawings:

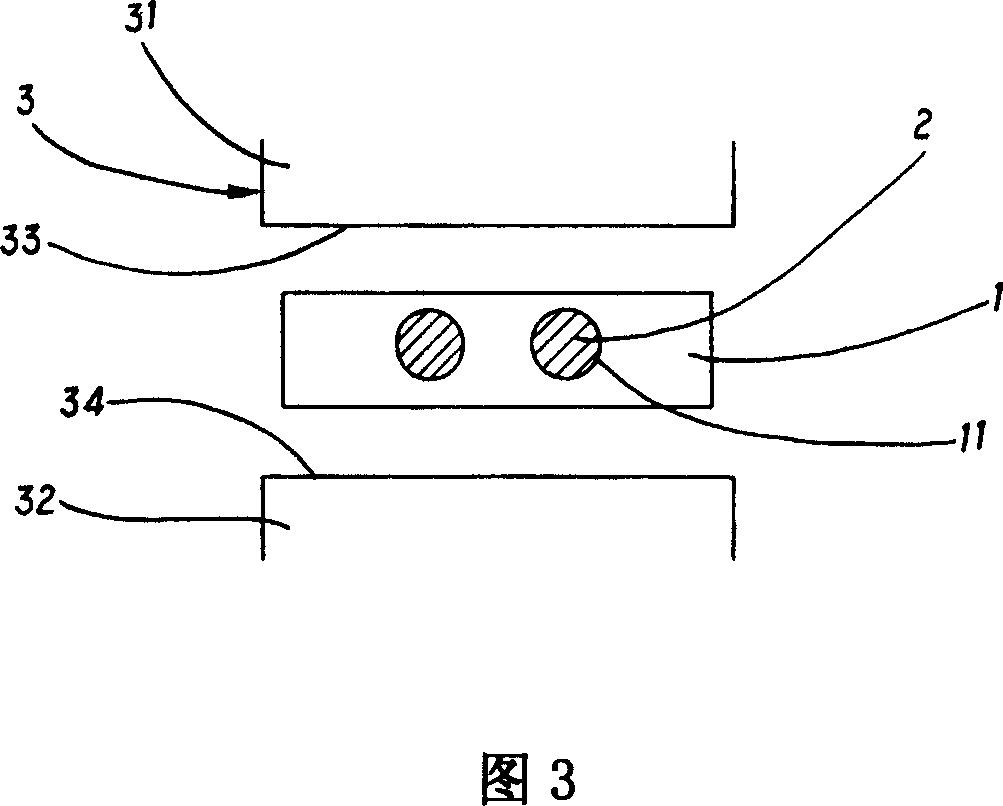

[0042] Please refer to Figures 1 to 6, which are schematic diagrams of the process steps of an embodiment of the combination method of the heat pipe and the heat conduction base of the present invention and the combined structure of the heat sink, as shown in the figure: the heat pipe and the heat conduction base of the present invention A combination method, the steps of which at least include:

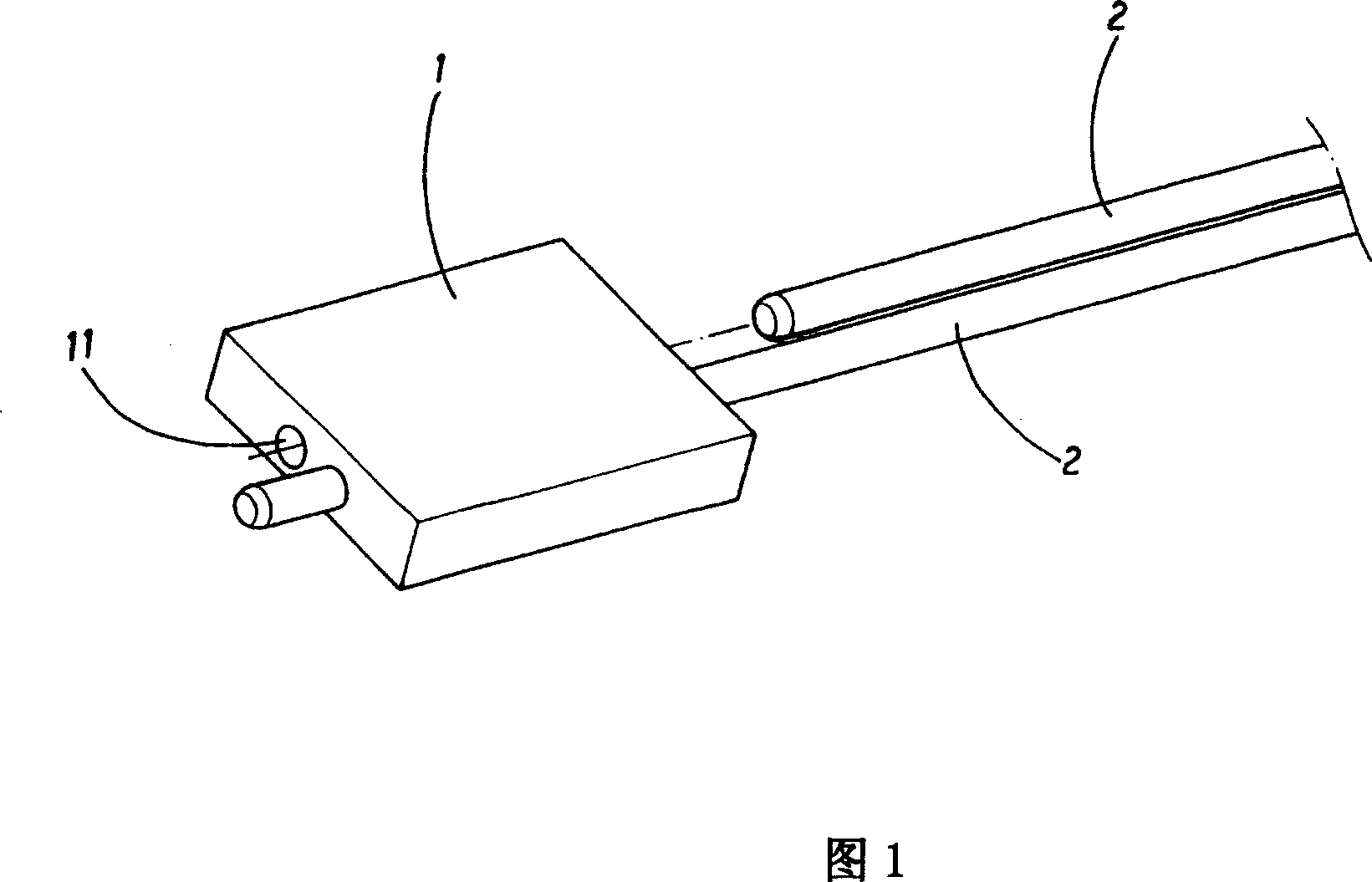

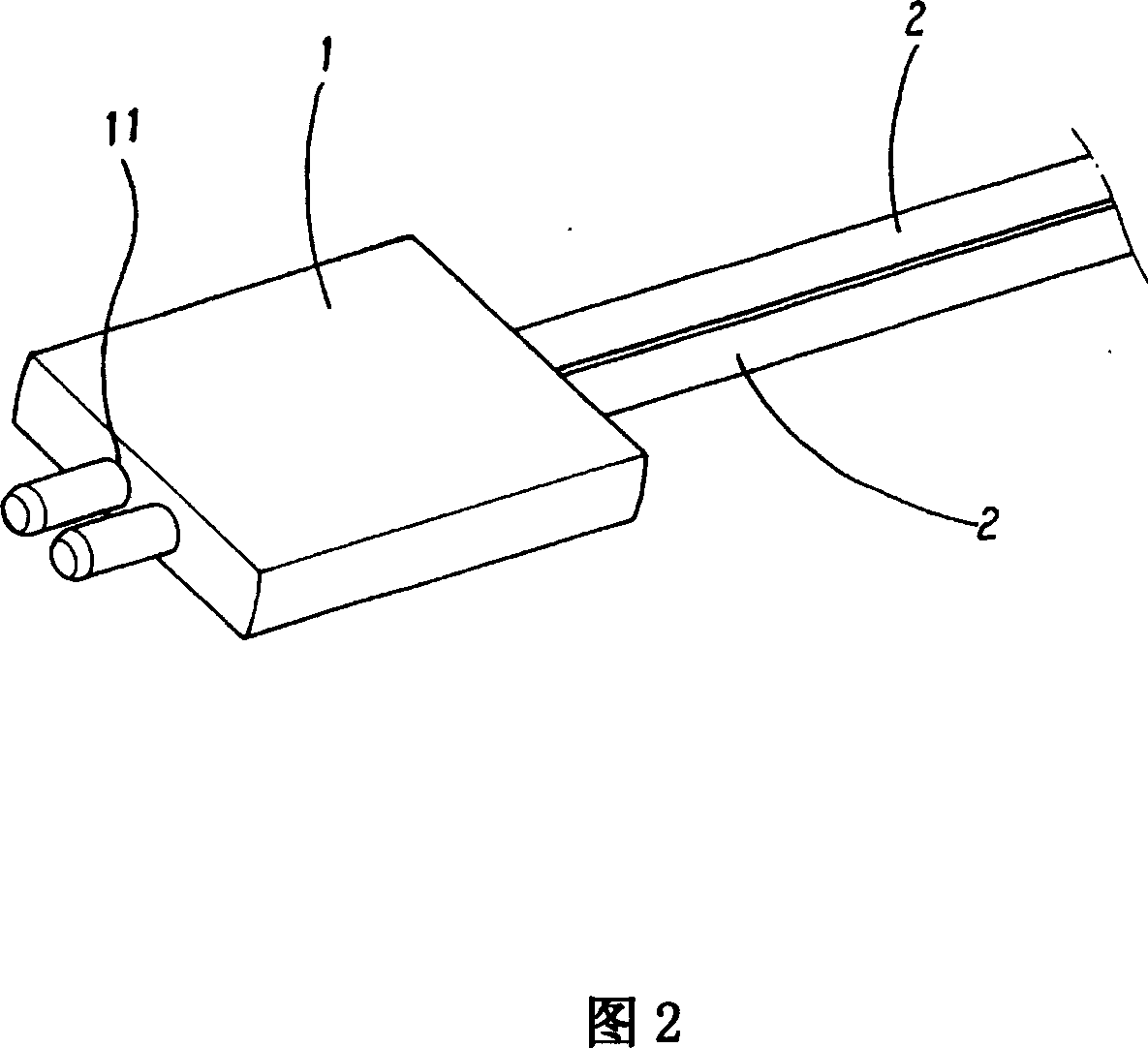

[0043] Step 1: Provide a heat-conducting bottom plate 1, at least one set of holes 11 is provided through its body, and the set of holes 11 is preferably biased against one surface side of the heat-conducting bottom plate 1, as shown in FIG. 1 ;

[0044] Step 2: Provide at least one heat pipe 2, and put each heat pipe 2 through the above-mentioned group of holes 11 respectively. As shown in FIG. Depending on requirements or designs;

[0045...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com