Femtosecond laser pulse produced microsize optical fiber Fabry-perot sensor and its production method

A femtosecond laser and optical fiber technology, which is applied in the use of optical devices to transmit sensing components, instruments, optics, etc., can solve the problems of limiting the application of MEMS sensors, difficult to reuse, and poor ability to withstand harsh environments, and achieve a unique axial direction. The effect of load characteristics and temperature response characteristics, easy mass production, and strong ability to withstand harsh environments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

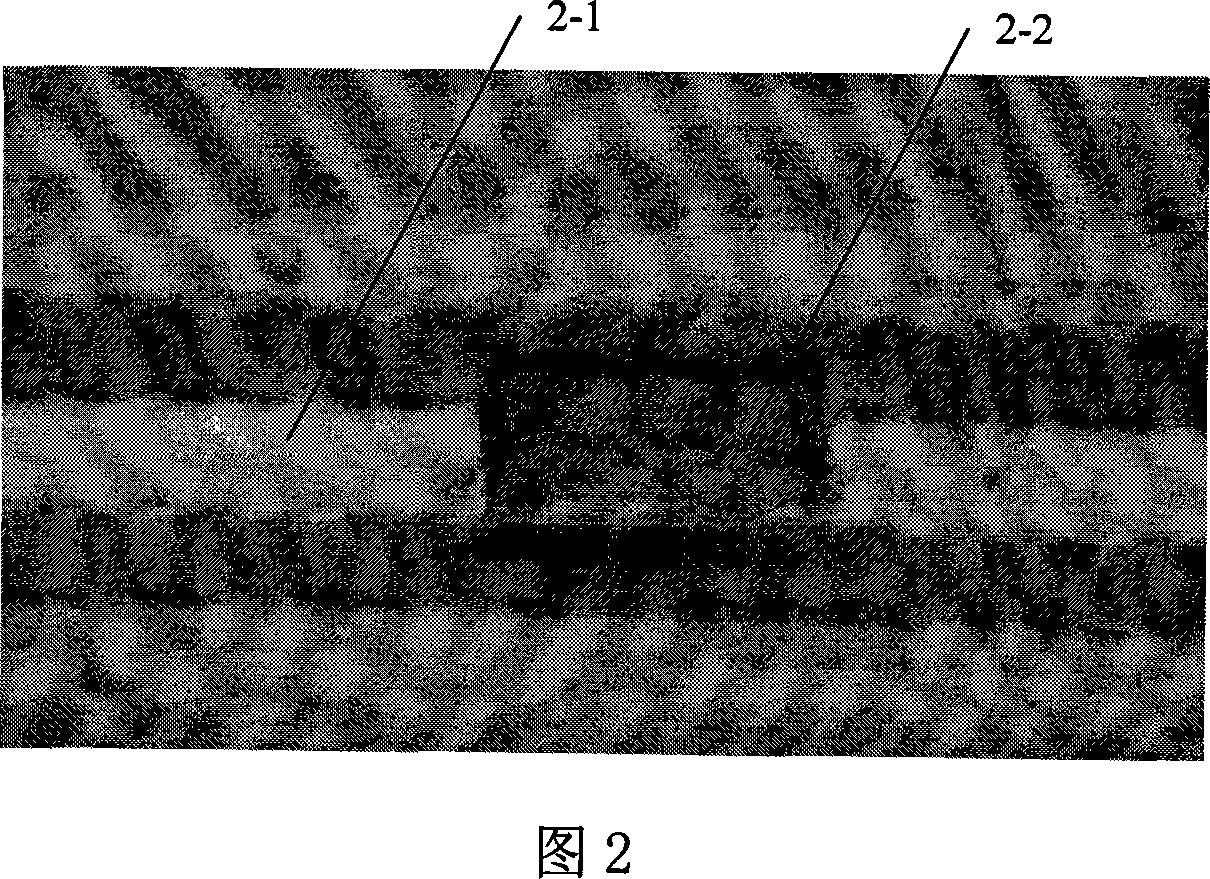

[0014] The miniature optical fiber F-P sensor made by femtosecond laser pulses is to make a small cavity (interference cavity) 2-2 that completely penetrates the fiber core and has a rectangular cross section on the common single-mode optical fiber 2-1. The depth h of the tiny cavity 2-2 satisfies: (D+d) / 2≤h≤D, where D is the diameter of the optical fiber, and d is the diameter of the fiber core.

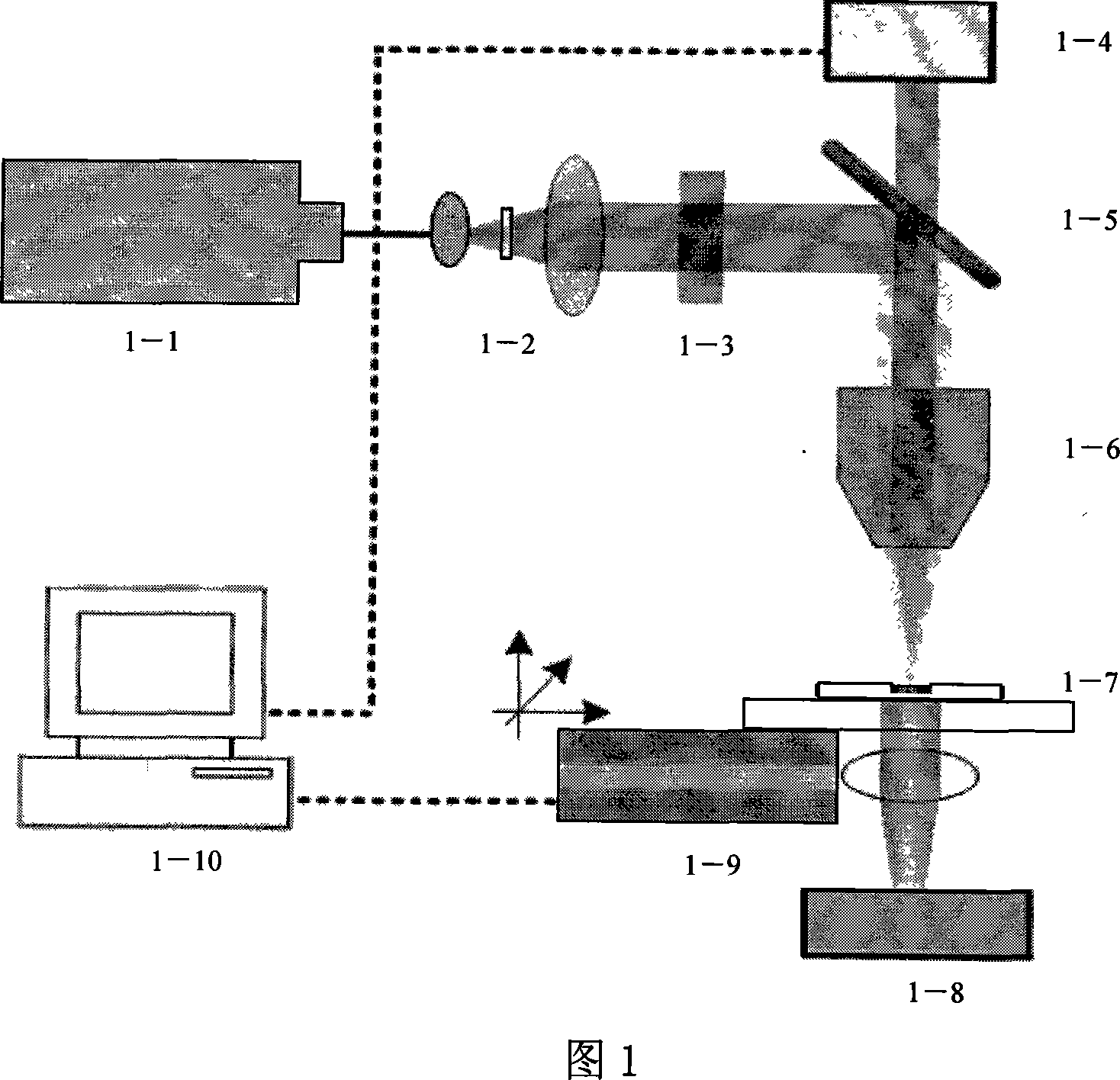

[0015] Figure 1 shows the principle diagram of making a micro-fiber F-P sensor with femtosecond laser pulses. In the figure, 1-1 is a femtosecond laser that generates ultrashort laser pulses, 1-2 is a collimating beam expander, and 1-3 is an attenuation 1-4 is a camera, 1-5 is a beam splitter, 1-6 is an objective lens, 1-7 is an ordinary single-mode fiber, 1-8 is an LED light source, 1-9 is a three-dimensional micro-motion stage, 1-10 for the computer. In the experiment, an ultrashort pulse laser with a pulse width of 120fs, a single pulse energy of 20μJ, a repetition rate of 1kHz ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com