Switch cabinet contact temperature monitoring and alarming system

A technology of contact temperature and alarm system, which is applied to thermometers, thermometers using directly heat-sensitive electric/magnetic elements, measuring devices, etc., can solve the impact of insulation performance and equipment life, the lack of self-test function of the detection system, Affect the safe and stable operation of equipment and other issues, to achieve the effect of extending the maintenance cycle, reducing maintenance costs and accident losses, and improving power supply reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with drawings and embodiments.

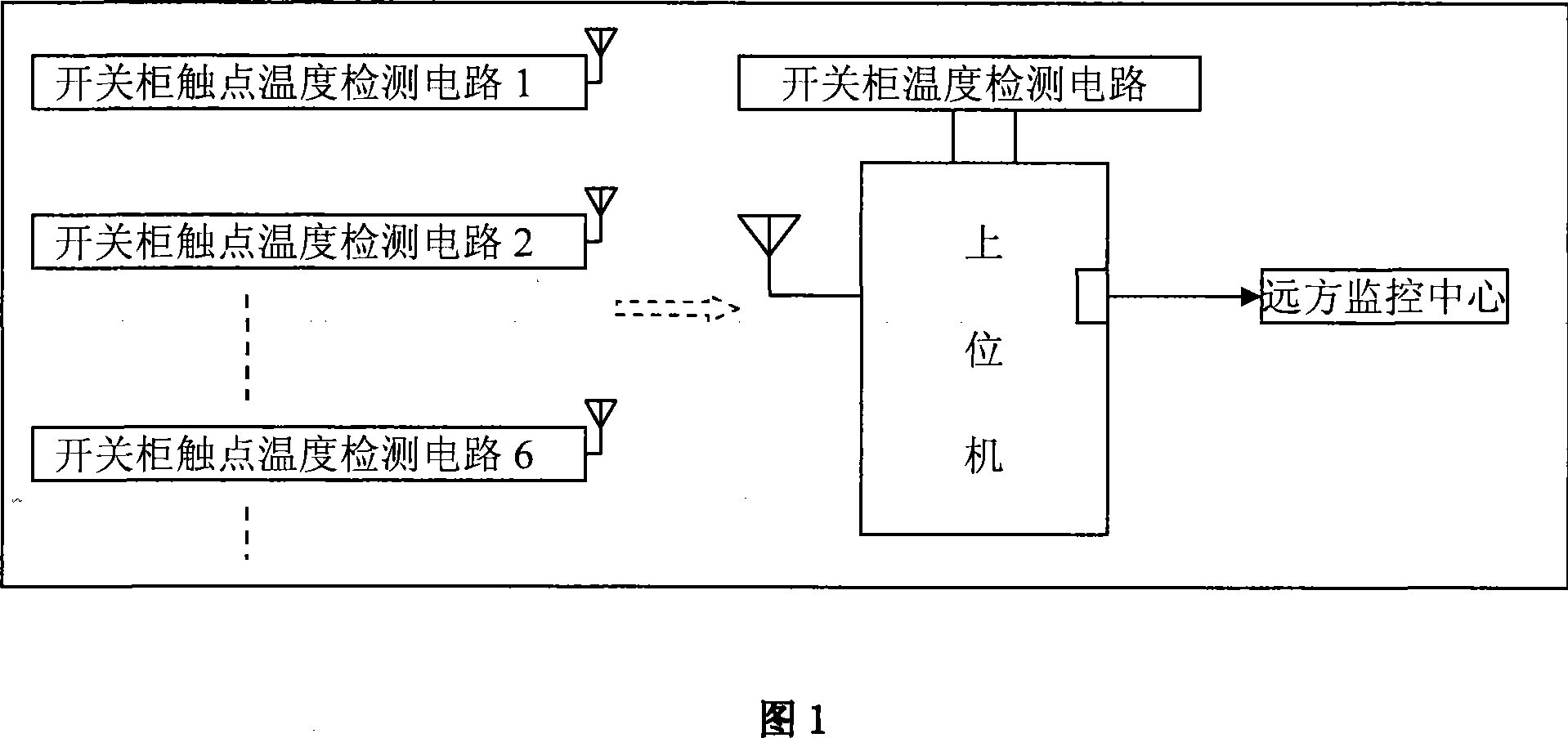

[0035] Fig. 1 is a schematic block diagram of the system structure of the present invention. The switchgear contact temperature monitoring and alarm system is composed of a switchgear temperature detection circuit, a plurality of switchgear contact temperature detection circuits, corresponding upper computers and remote monitoring centers;

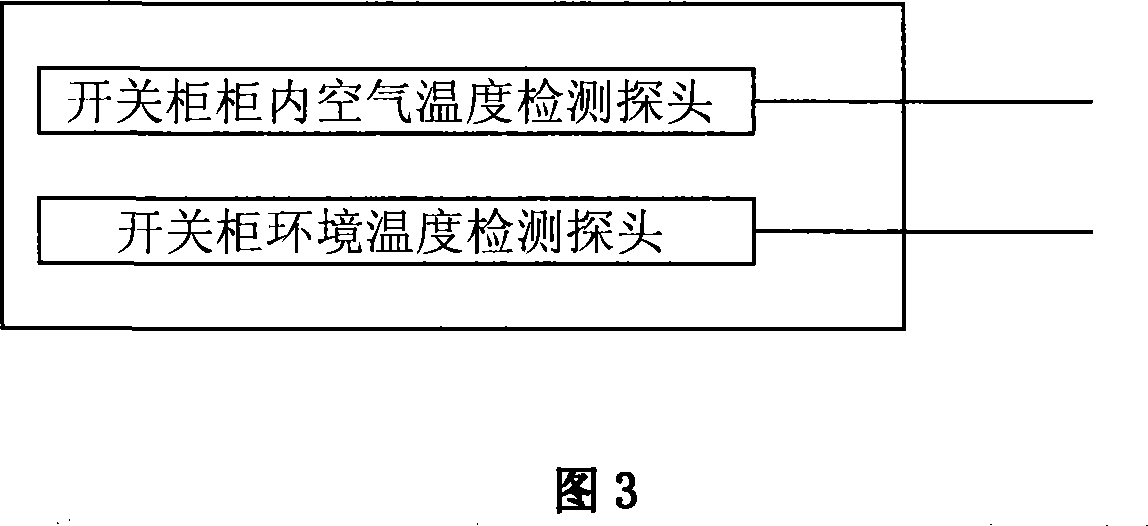

[0036] The temperature detection circuit of the switch cabinet is composed of the air temperature detection probe in the switch cabinet and the ambient temperature detection probe of the switch cabinet;

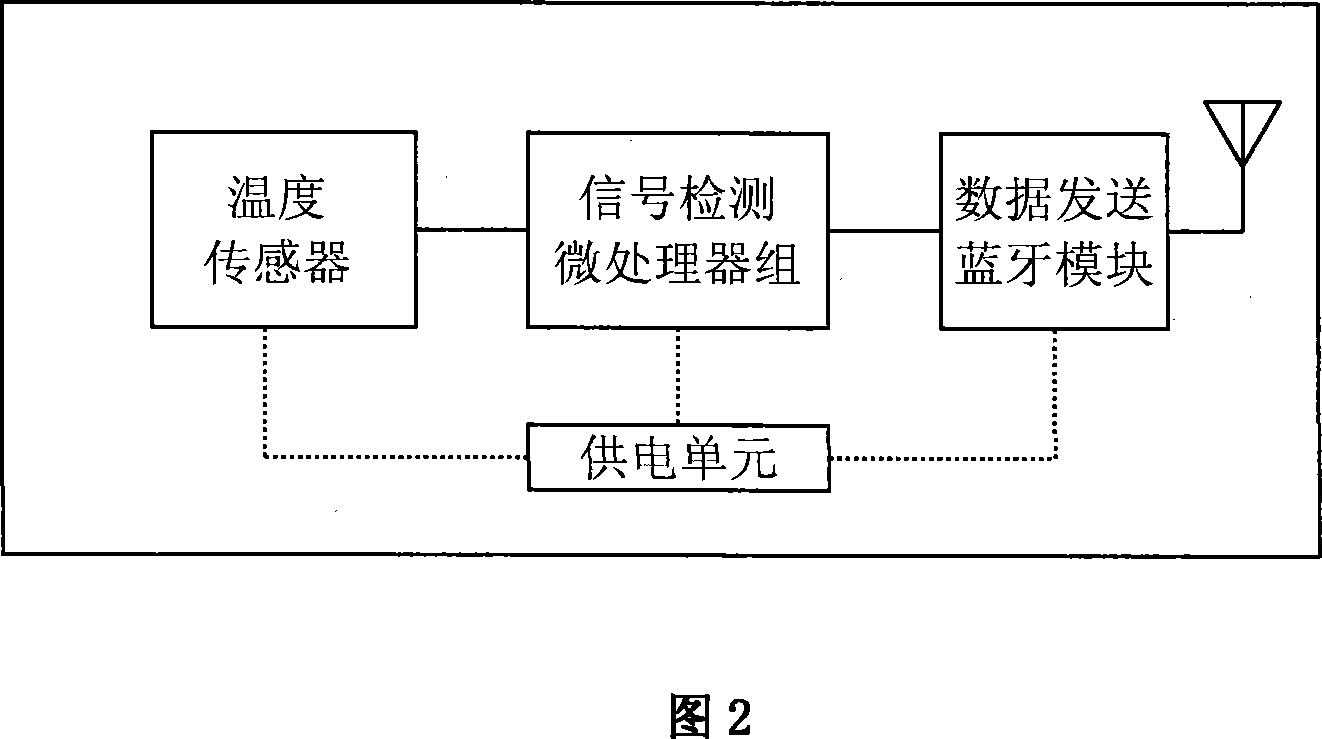

[0037] The switch cabinet contact temperature detection circuit is composed of a power supply unit, a temperature sensor, a signal detection microprocessor group and a data transmission Bluetooth module. The power supply unit supplies power to the detection circuit; the temperature sensor completes continuous detection of the contac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com