Battery charger

A technology for battery chargers and chargers, which is applied to battery circuit devices, current collectors, electric vehicles, etc., and can solve the problems of chargers not having the function of recharging in reverse connection, increasing circuit costs, charging, etc., to reduce the number of components and The effect of PCB board area and circuit cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

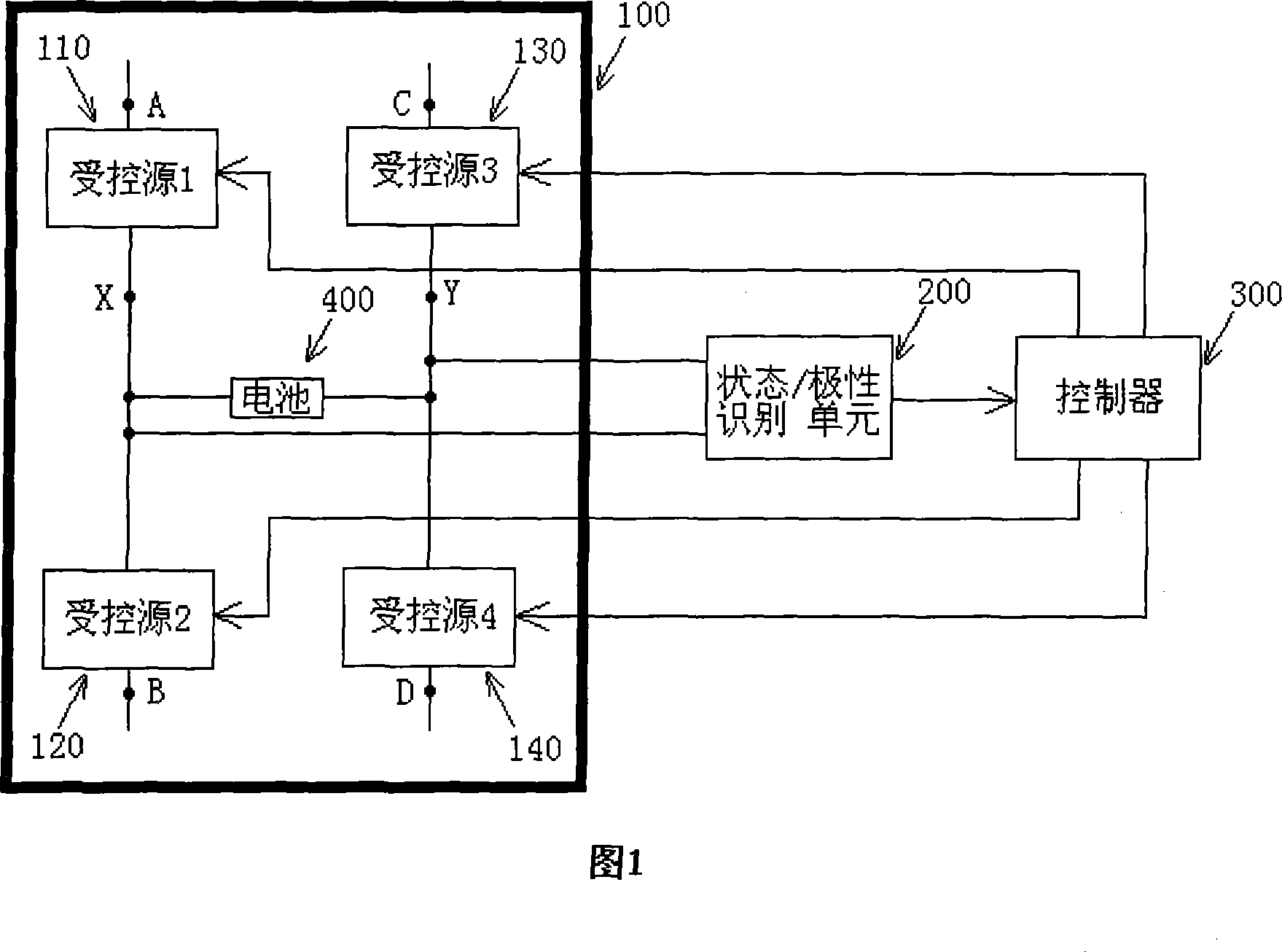

[0014] Most of the known battery chargers need to manually or use other devices to adjust the battery polarity to complete the normal charging function when the battery is reversed. Some chargers have the function of recharging the battery, but they are all built with discrete components. , occupying a large PCB board area, and accurate detection voltage will further increase the circuit cost. In view of this, the present invention proposes a battery charger that can automatically identify the polarity of the battery and can charge the battery in reverse connection.

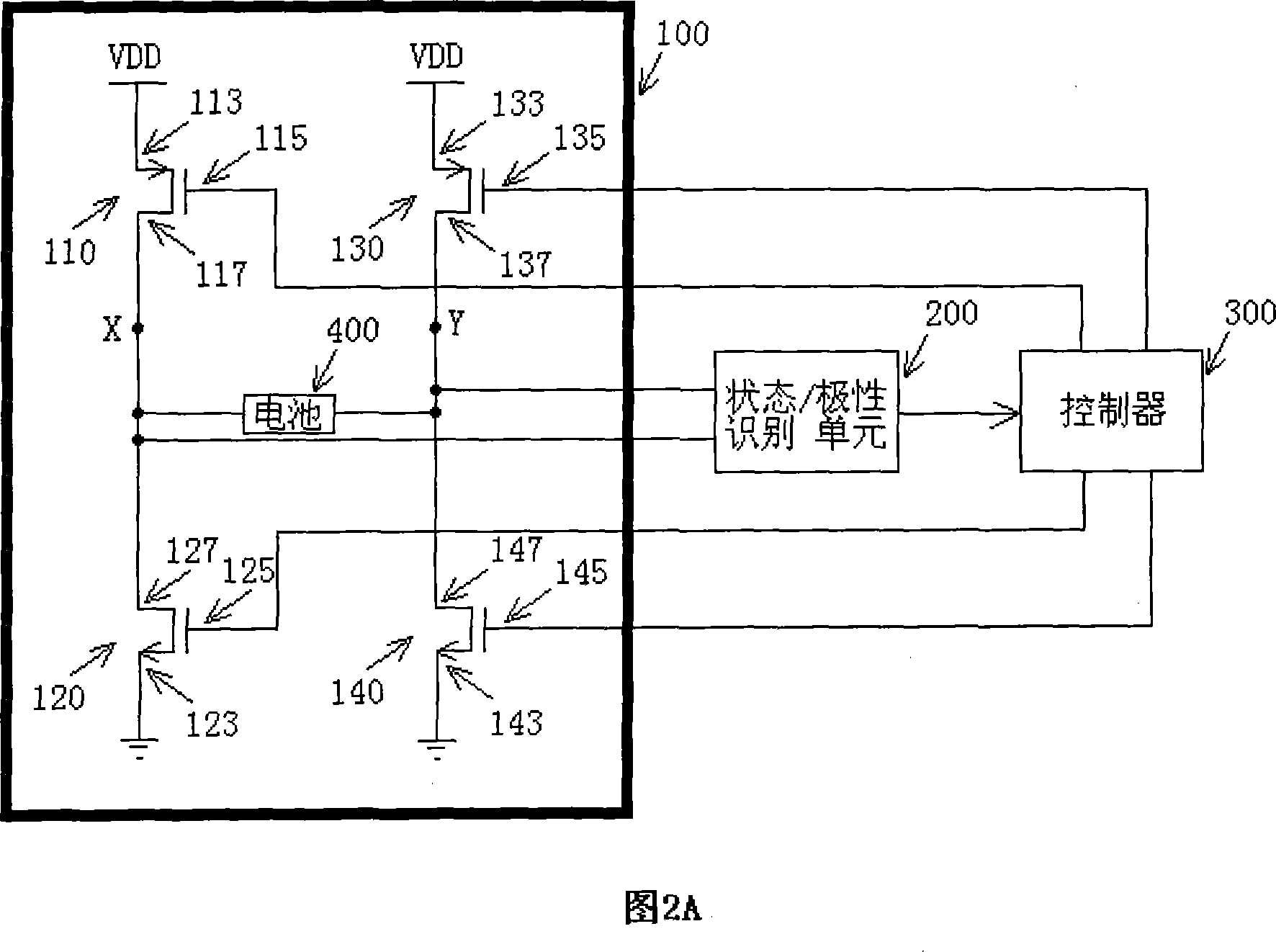

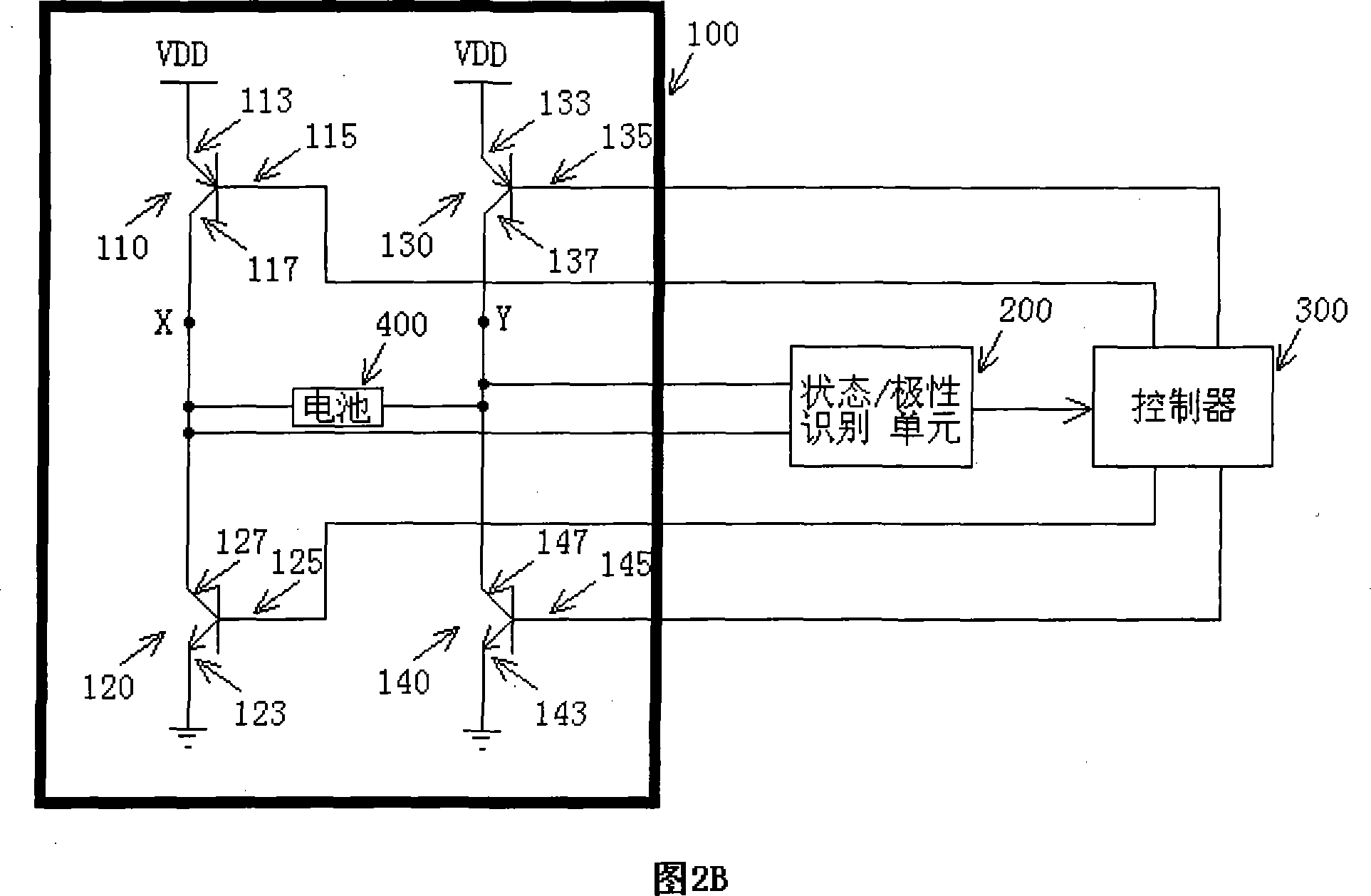

[0015] As shown in Fig. 2A, this figure is a simple schematic diagram of a preferred embodiment of the present invention. In this example, a MOS field effect transistor is used as a controlled source, wherein the first field effect transistor (110) is a P channel MOS transistor, which has a source (113), a drain (117) and a gate (115), wherein The source (113) is connected to the power supply, the drain (117) is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com