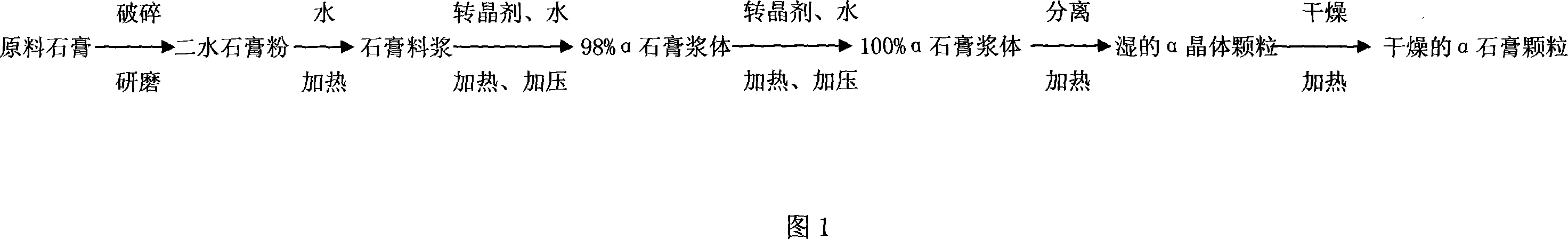

Process for producing alpha gypsum powder by liquid phase method

A technology of gypsum powder and liquid phase method, which is applied in the field of α gypsum powder production, which can solve problems such as unstable product performance, uneven heating, temperature adjustment, etc., and achieve stable product performance, small restrictions, and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Grade > 95% massive transparent dihydrate gypsum, crushed to obtain gypsum with block size 2 The gypsum slurry (measured by the density measurement system) is initially heated to 55°C by heat-conducting oil, and then pumped into the crystal converter through a high-pressure slurry pump, where it is further diluted with water and added with crystal Add maleic anhydride, and raise the temperature to 125°C with a small increase in temperature. At this time, the gypsum crystals react under the crystal modifier and a pressure of 3.0 MPa to form α-gypsum crystals, and the crystal modifier dosage is controlled as needed to control the shape of the crystals. At the same time, at regular intervals, samples are taken from the sampling hole and observed under a microscope. When it is found that most of the gypsum (about 98%) is converted into regular α-gypsum crystals, the α-crystal slurry is pumped into the next turn by using the pressure difference. Crystallizer, carry out secon...

Embodiment 2

[0030] Grade > 90% massive transparent dihydrate gypsum, after crushing to obtain gypsum with block size 2 The gypsum slurry (measured by the density measurement system) is initially heated to 50°C by heat transfer oil, and then pumped into the crystal converter through a high-pressure slurry pump, where it is further diluted with water and added with crystal Add maleic anhydride, and raise the temperature to 98°C with a small increase in temperature. At this time, the gypsum crystals react under the crystal modifier and a pressure of 3.5 MPa to form α-gypsum crystals, and the crystal modifier dose is controlled as needed to control the shape of the crystals. At the same time, at regular intervals, samples are taken from the sampling hole and observed under a microscope. When it is found that most of the gypsum (about 98%) is converted into regular α-gypsum crystals, the α-crystal slurry is pumped into the next turn by using the pressure difference. crystallizer, carry out sec...

Embodiment 3

[0035] The fibrous gypsum with a grade > 97% is crushed to obtain gypsum with a block size of 2 (measured by a density measuring system) gypsum slurry, the gypsum slurry is initially heated to the corresponding temperature of 35°C by heat-conducting oil, and then pumped into the crystal converter through a high-pressure slurry pump, where it is further diluted with water and added Crystal transformation agent maleic anhydride, and raise the temperature to 110°C with a slight temperature increase. At this time, the gypsum crystals react under the crystal modifier and the pressure of 4.3 MPa to form α-gypsum crystals, and the dosage of the crystal modifiers is controlled as needed to control the shape of the crystals. At the same time, at regular intervals, samples are taken from the sampling hole and observed under a microscope. When it is found that most of the gypsum (about 97%) is converted into regular α gypsum crystals, the α crystal slurry is pumped into the crystal conver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com