Intelligent identification method of metallurgical mine phase

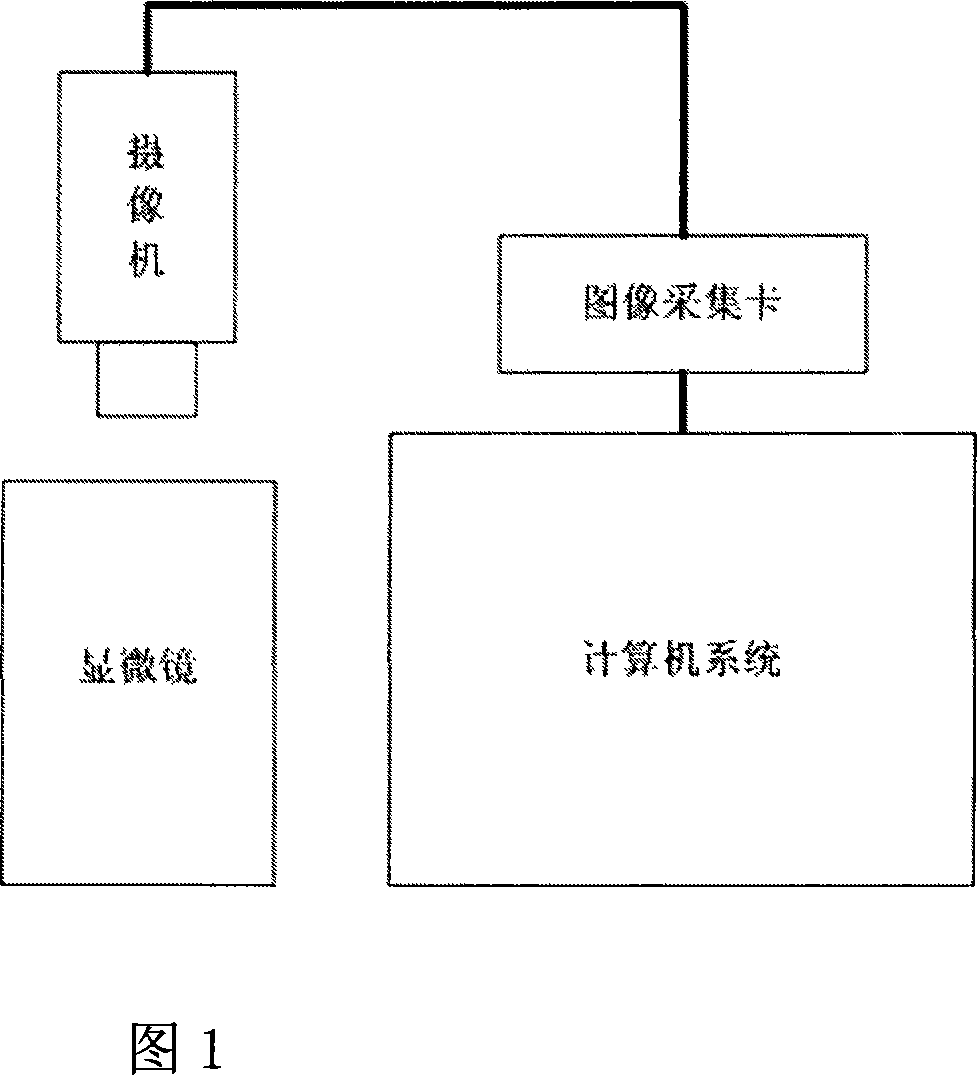

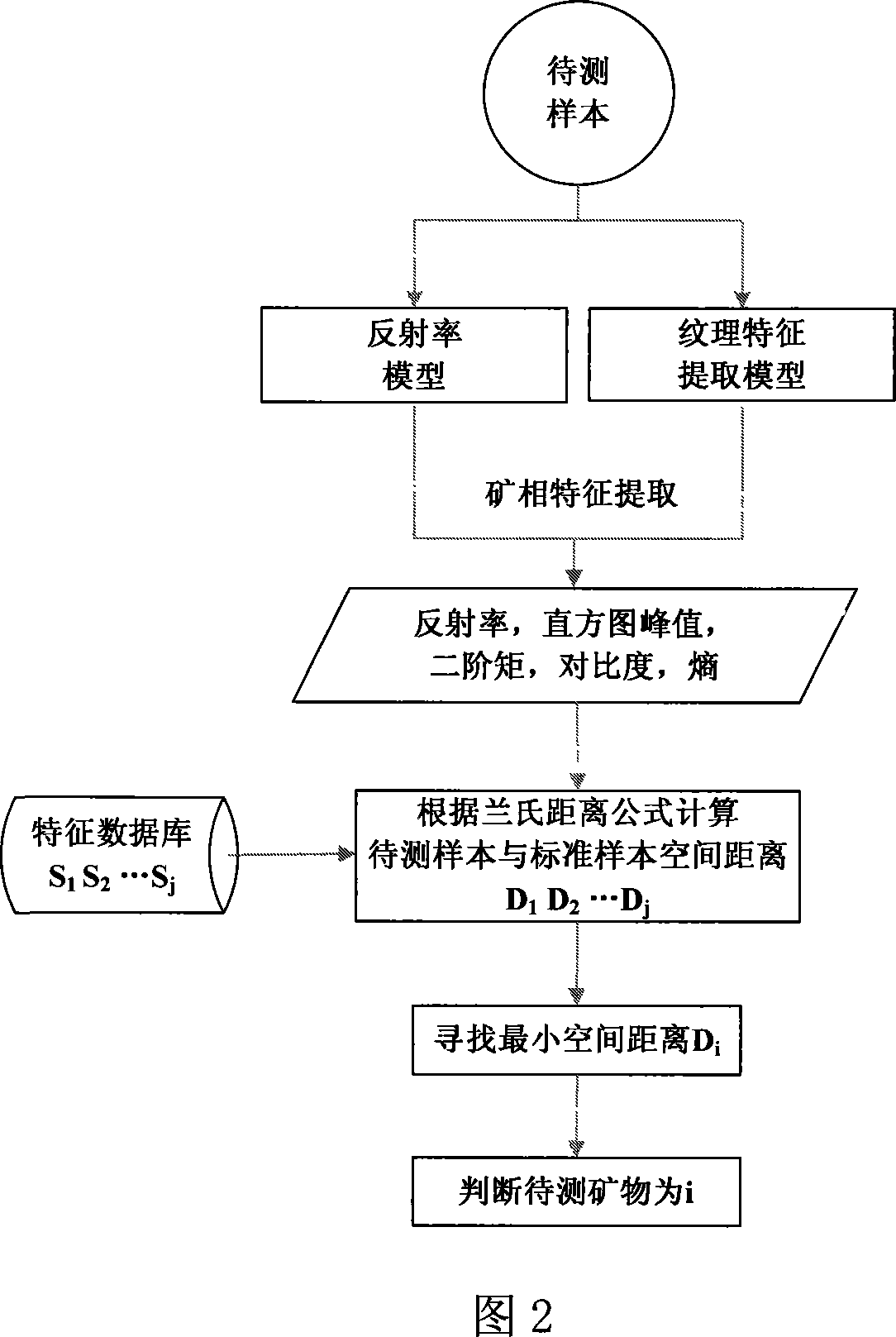

A technology for intelligent identification and ore phase, applied in the field of metallurgy, which can solve the problems of indistinguishable size and distribution of pores in sintered ore, difference in identification results, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0115] 1. Establish standard mineral phase database

[0116] mineral

name

the peak

Interval 1

the peak

Interval 2

the peak

Interval 3

second moment

contrast

entropy

calcium ferrite

22~25

20

18~18.5

41~51

7~8

45~49

98~102

74~83

77~85

136~138

127~128

113~116

0.0884

0.0465

0.1781

4.8475

3.5724

6.0078

5.1680

4.3092

3.3286

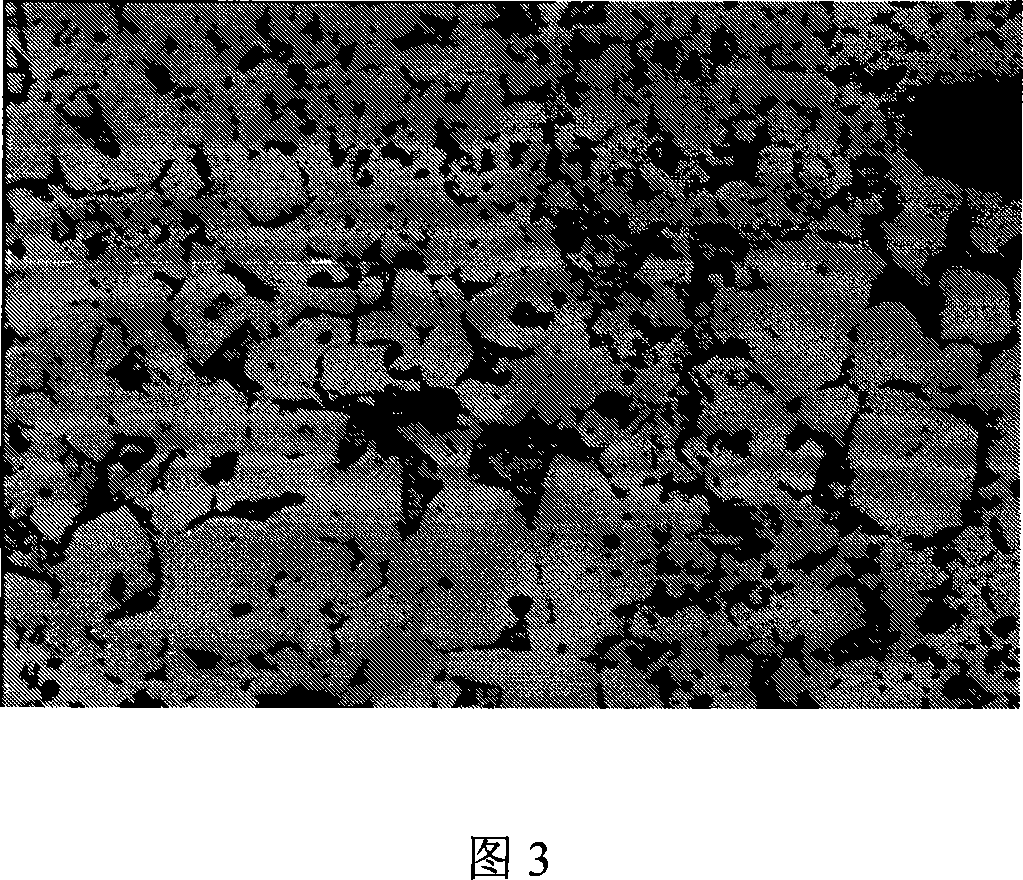

[0117] 2. Extract the characteristics of the ore sample to be tested (as shown in Figure 3 and Figure 4)

[0118] mineral

name

the peak

Interval 1

the peak

Interval 2

the peak

Interval 3

second moment

contrast

entropy

to be tested

mineral

20.7

7~8

43~44

1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com