Hand-held mobile electronic visiting system with fingerprint identity recognition function, and the visiting method

An identification, mobile technology, applied in character and pattern recognition, inspection time patrol, instruments, etc., to achieve the effect of easy offline use, convenient use and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

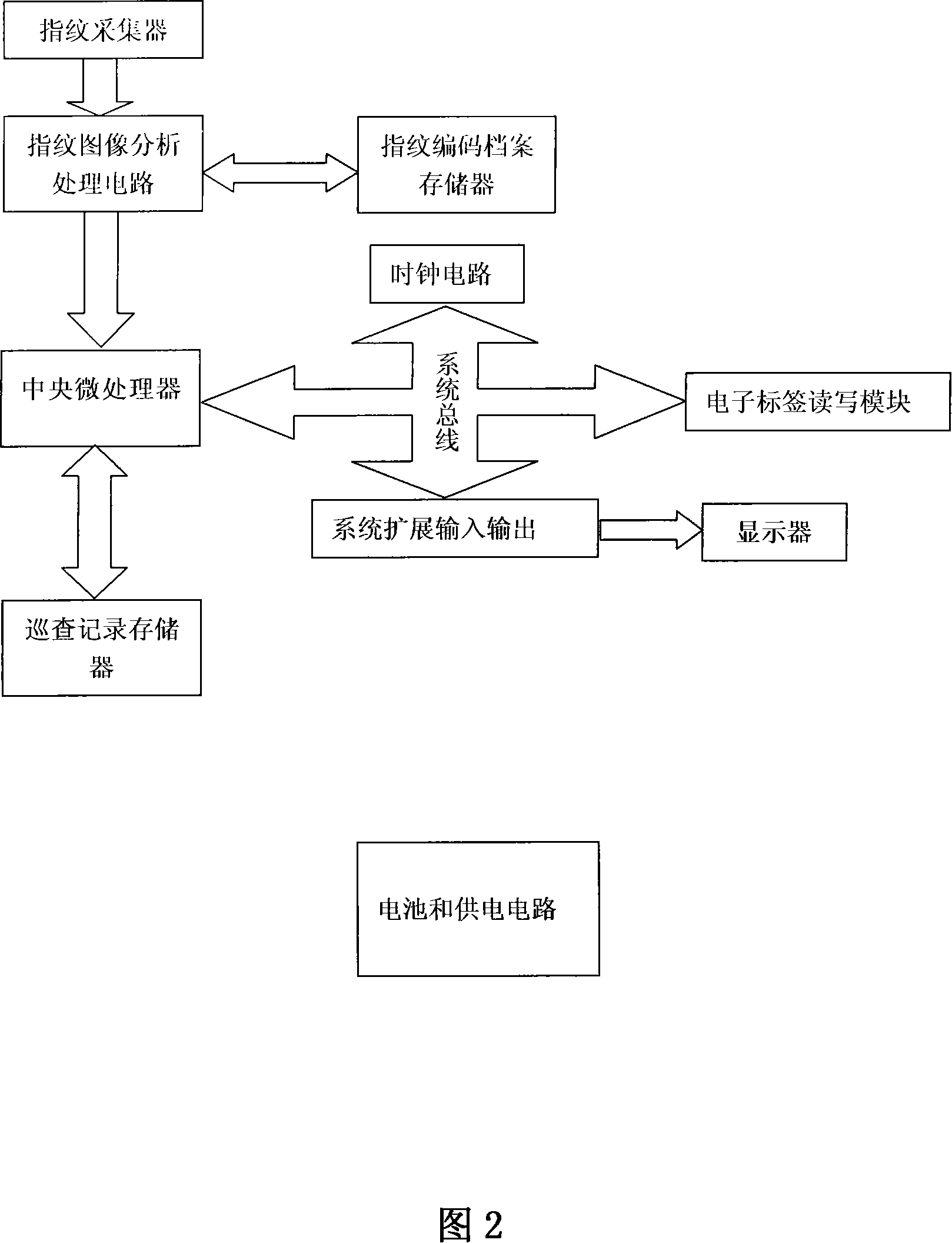

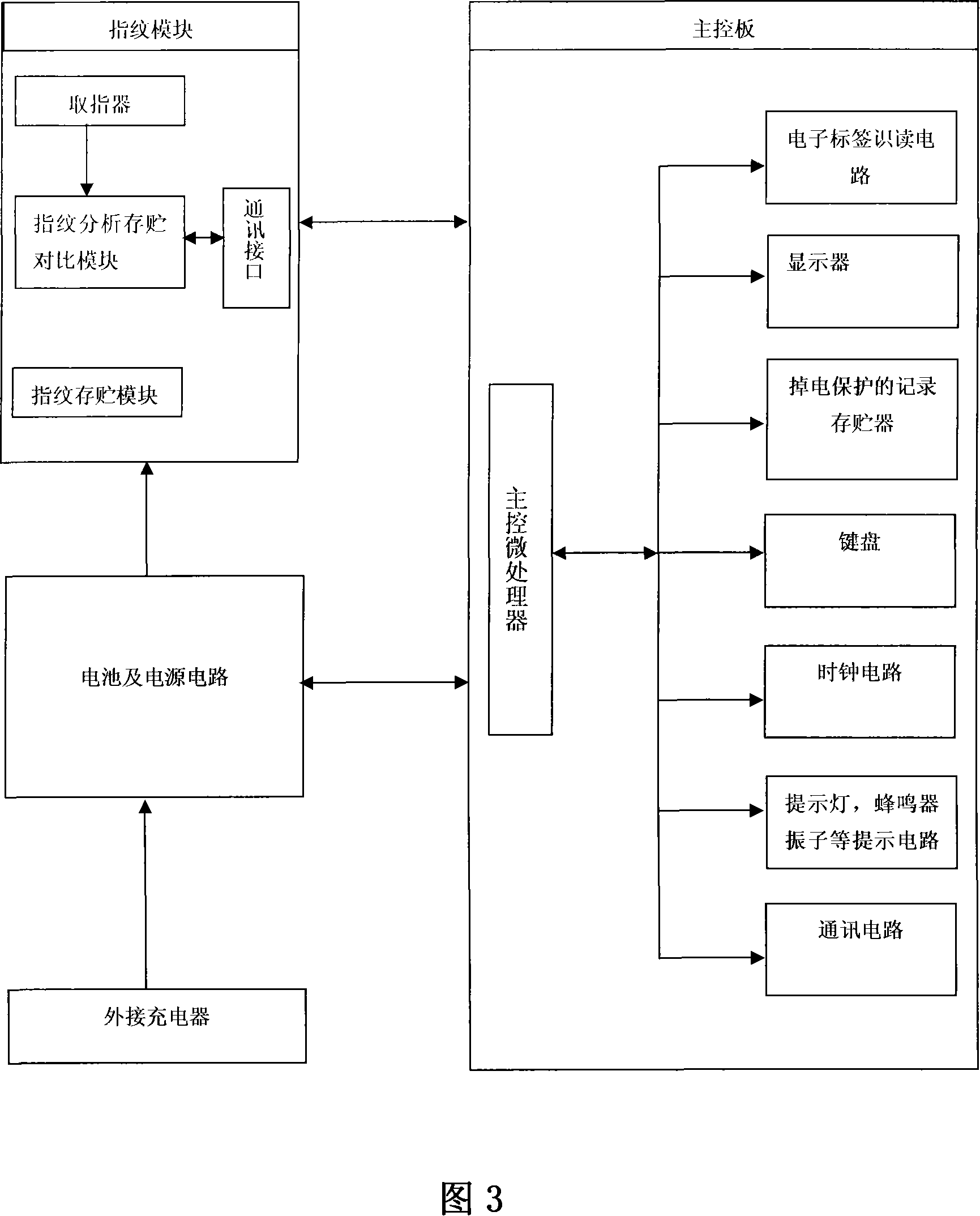

[0036] According to the different electronic tags used in the system, they are divided into two categories: contact type (represented by DALLAS information button) and non-contact type (that is, inductive type, represented by EM induction card and TI induction card). In addition to the principle of reading electronic tags Except for the difference, other working principles and processes are basically similar.

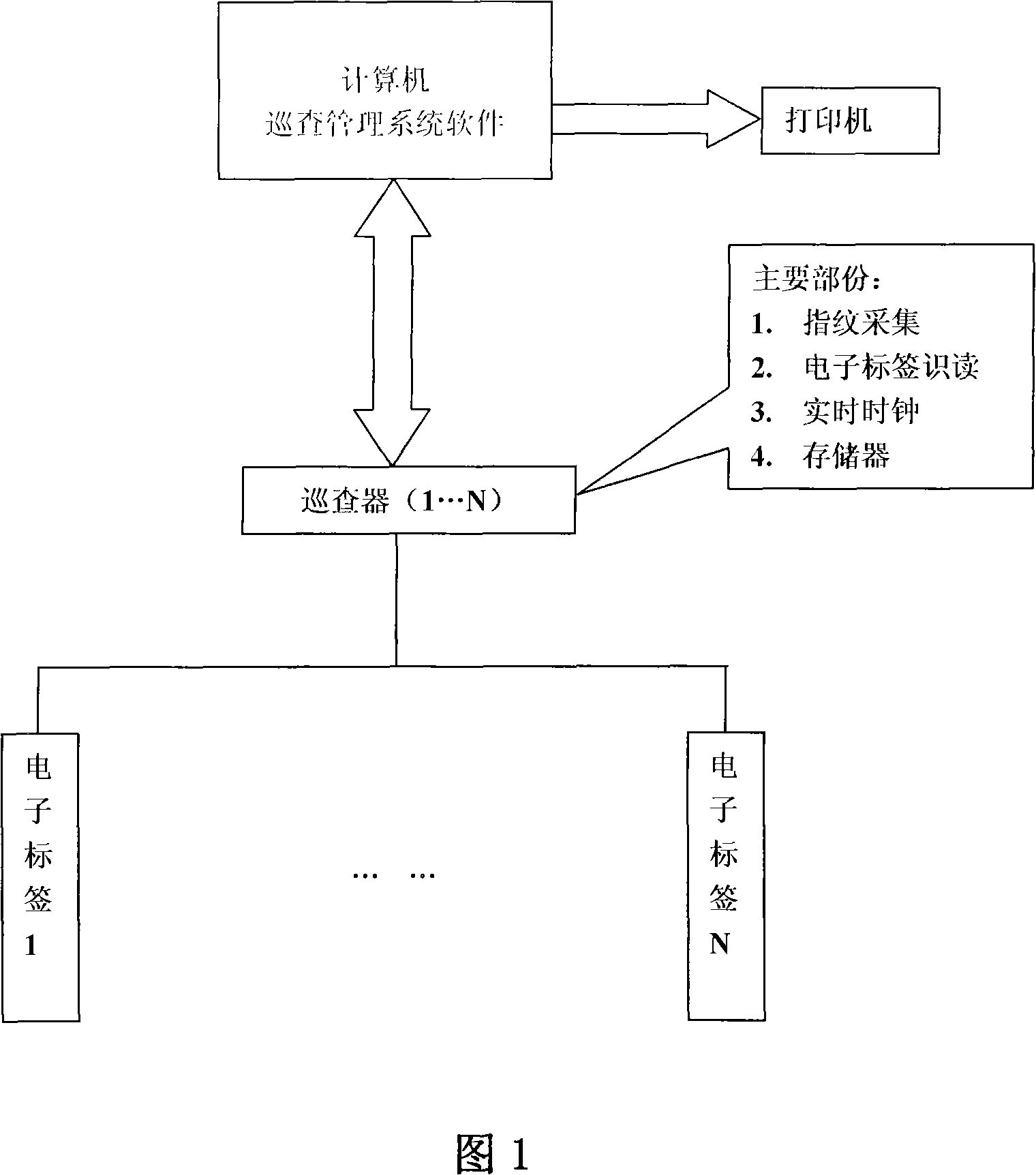

[0037] Components: 1) Electronic label: contains electronic code information (the code of each electronic label is unique and cannot be copied, so as to identify a specific inspection location). Place electronic tags with different codes on the equipment or lines to be inspected (no wiring, no power supply), and store the codes of the electronic tags and the corresponding placement information in the computer inspection management software. Patroller: Read electronic tags and store inspection records, which include electronic tag numbers, time of arrival at the inspecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com