Manufacturing facility and super finishing apparatus for ball bearing

A technology for ball bearings and manufacturing equipment, applied in the direction of superfinishing machines, manufacturing tools, ball bearings, etc., to achieve the effect of improving dimensional accuracy and shape accuracy, and improving the rate of results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

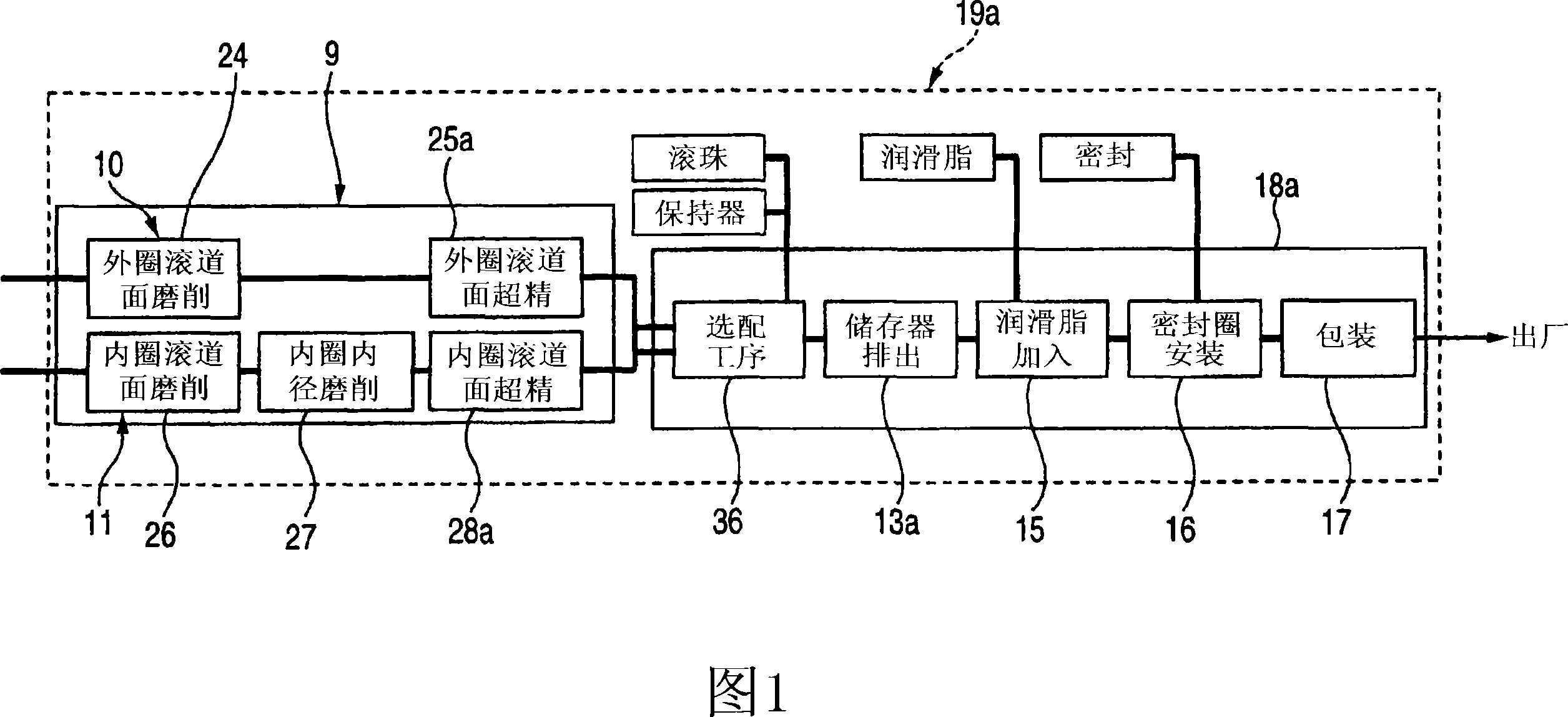

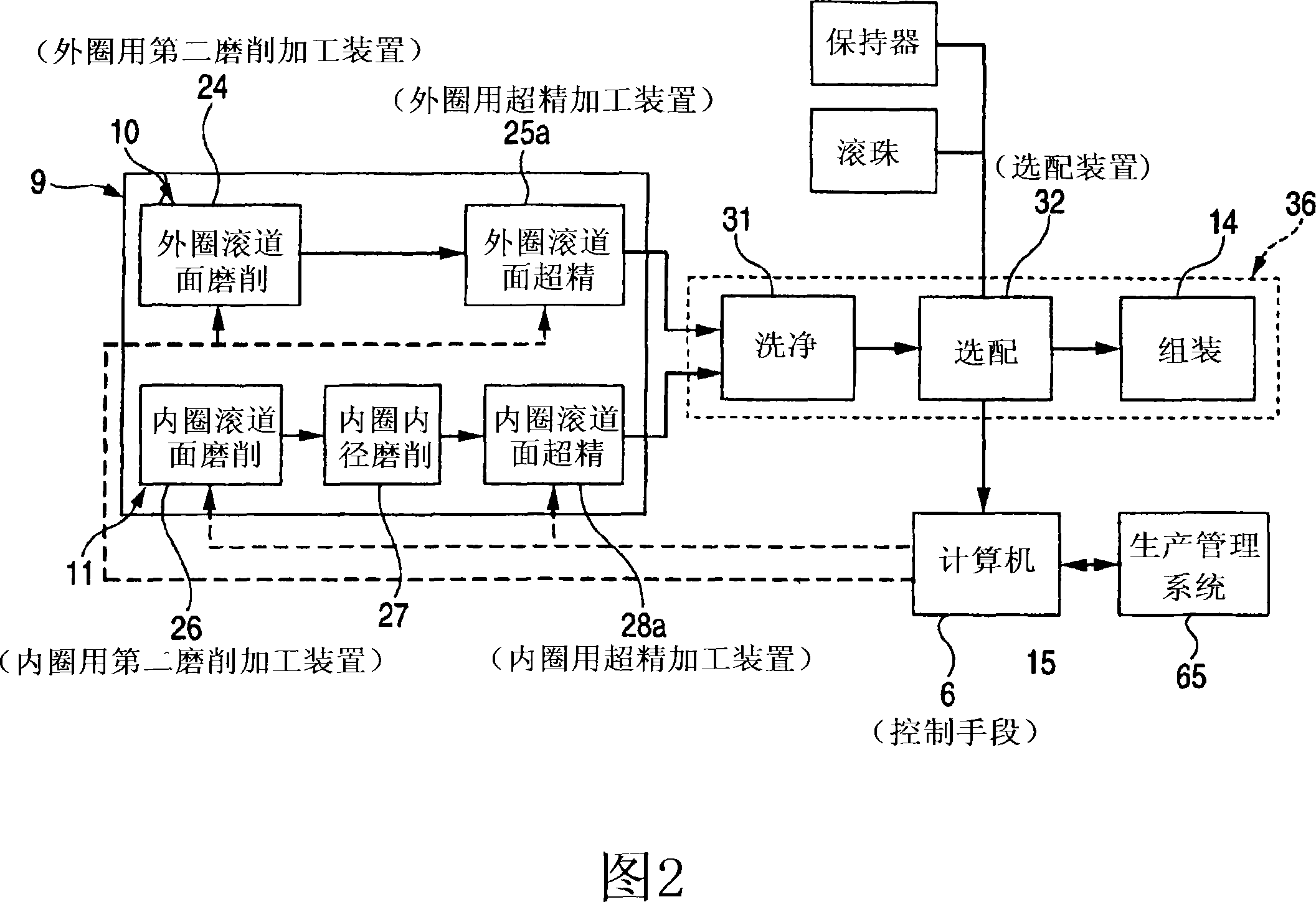

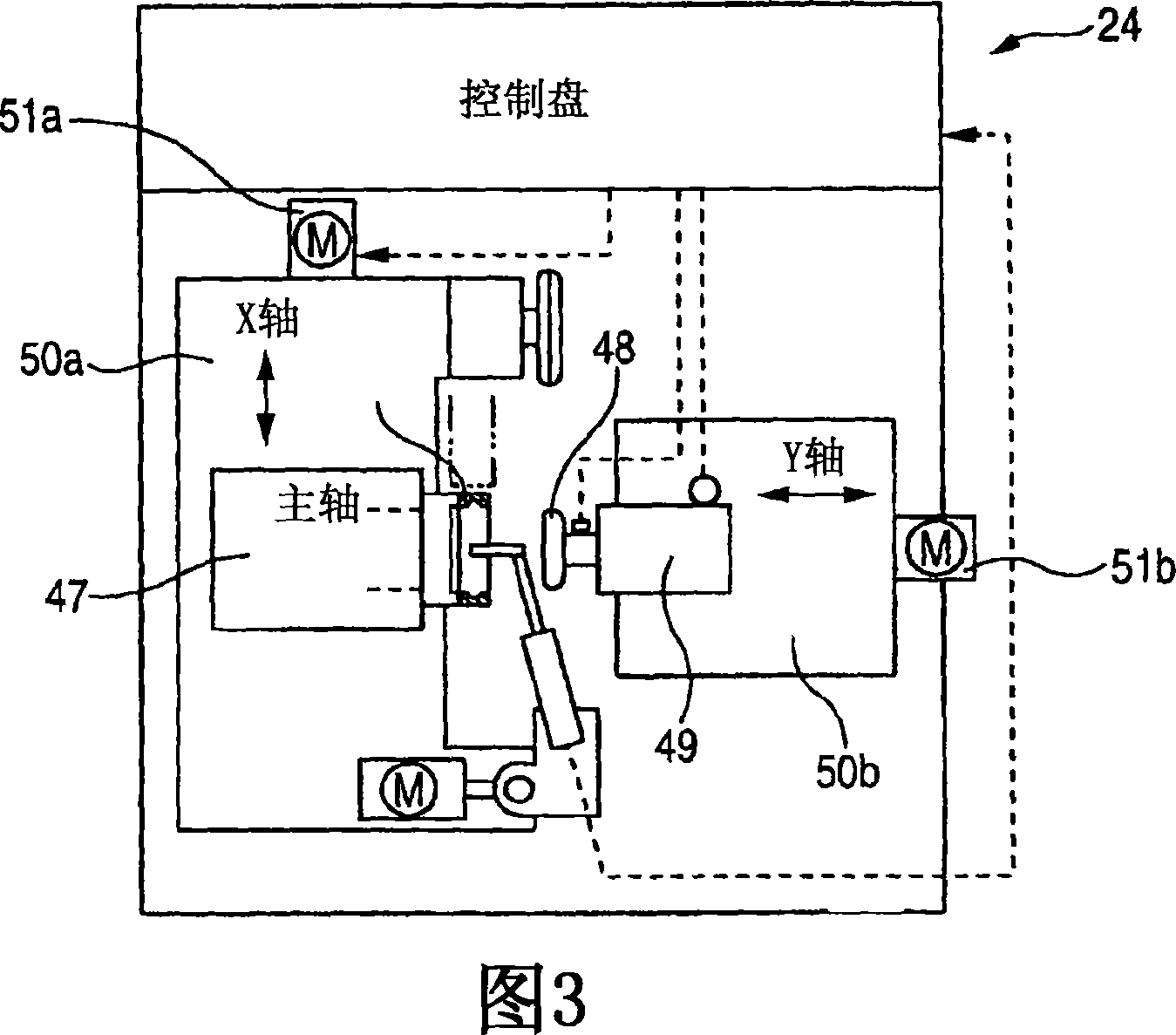

[0131] 1 to 4 show embodiments of the present invention. In the case of the ball bearing manufacturing equipment of this embodiment, the outer ring 1 and the inner ring 2 (refer to FIG. 6 ) of the workpiece (workpiece) or the conveyance direction (flow direction) of the intermediate assembly (left and right in FIG. 1 Direction), between the optional assembly equipment 36 and the grease adding device 15, a reservoir 13a that can accommodate and discharge a plurality of the above-mentioned intermediate assemblies is provided. In addition, as shown in FIG. 2, the optional assembly facility 36 includes a cleaning device 31 for cleaning the outer ring 1 and the inner ring 2 after grinding and superfinishing. An optional device 32 for assembling the outer ring 1, inner ring 2, and balls 3 (refer to Figure 6) of appropriate size, the outer ring 1, inner ring 2, multiple balls 3 and cage delivered from the optional device 32 An assembly device 14 for assembling to form an intermediat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com