Apparatus for operating gas and providing for observing under vacuum or low-voltage environment

A low-pressure environment, gas technology, applied in the direction of measuring devices, electrical components, instruments, etc., can solve problems such as operation, electron beam cannot be imaged smoothly, and electron beam focusing distance changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0097] In order to describe the structure and characteristics of the present invention in detail, the following eleven preferred embodiments are given and described in conjunction with the drawings as follows, wherein:

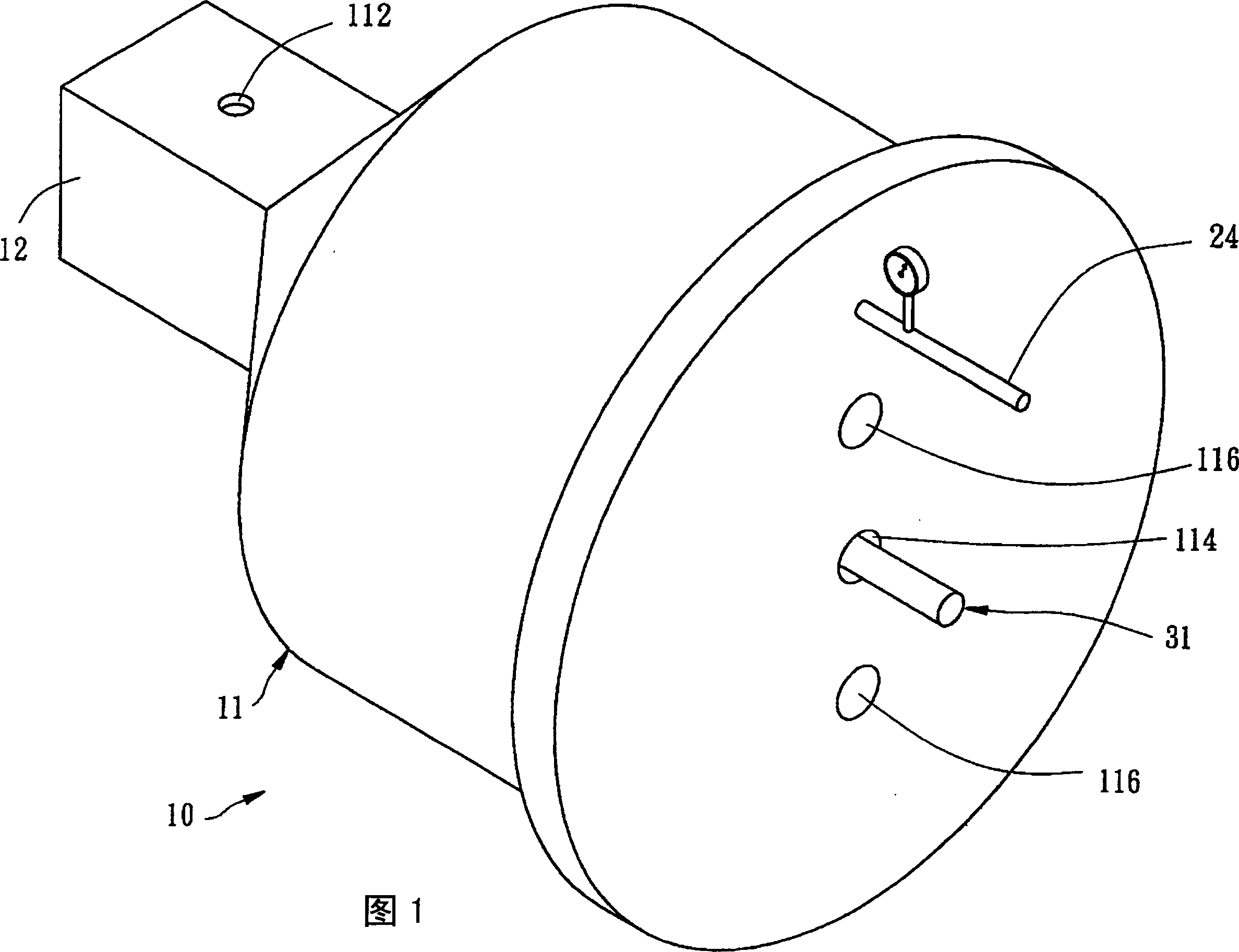

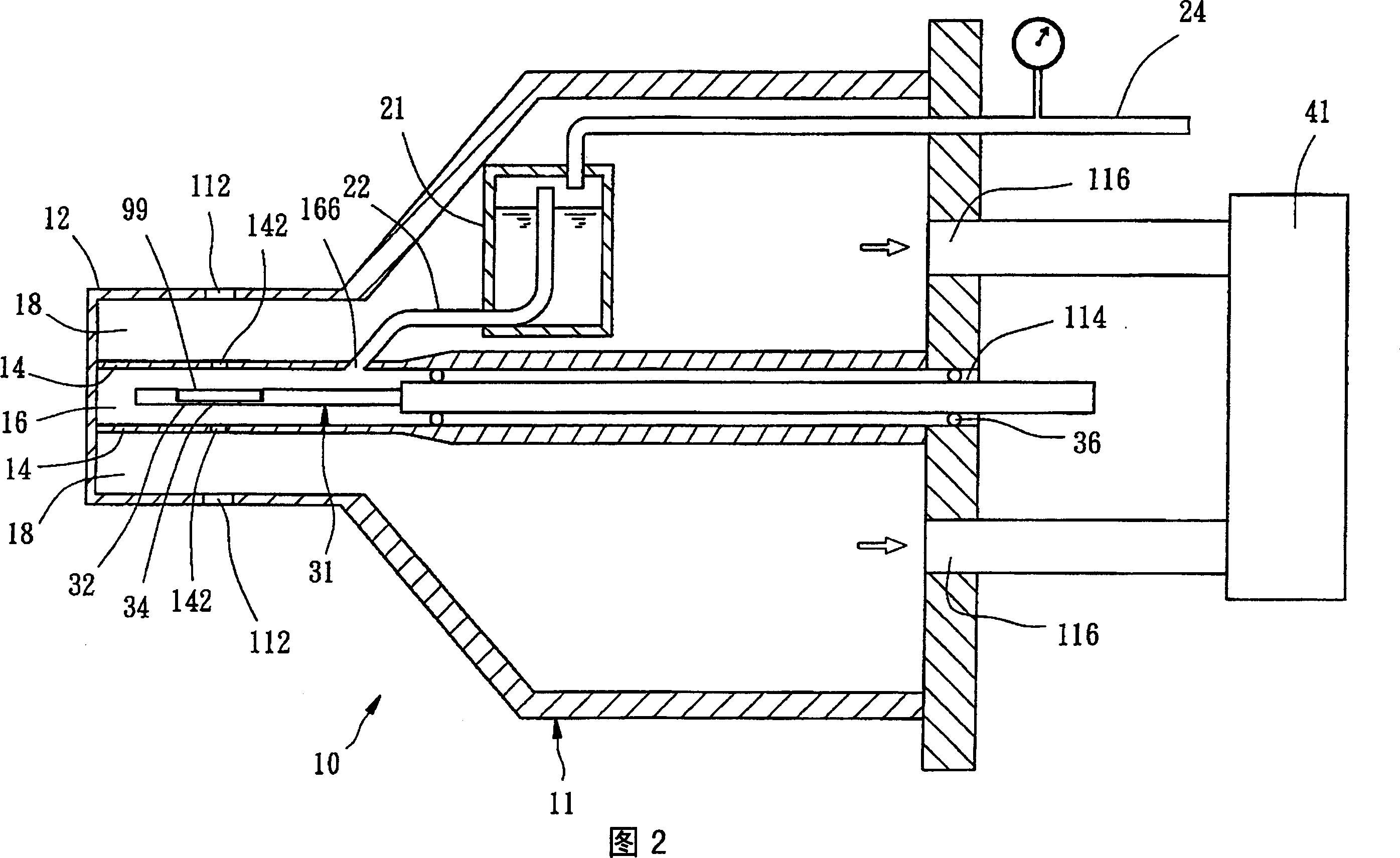

[0098] As shown in Figures 1 to 2, the first preferred embodiment of the present invention provides an observational device 10 for operating gas in a vacuum or low-pressure environment, which mainly includes:

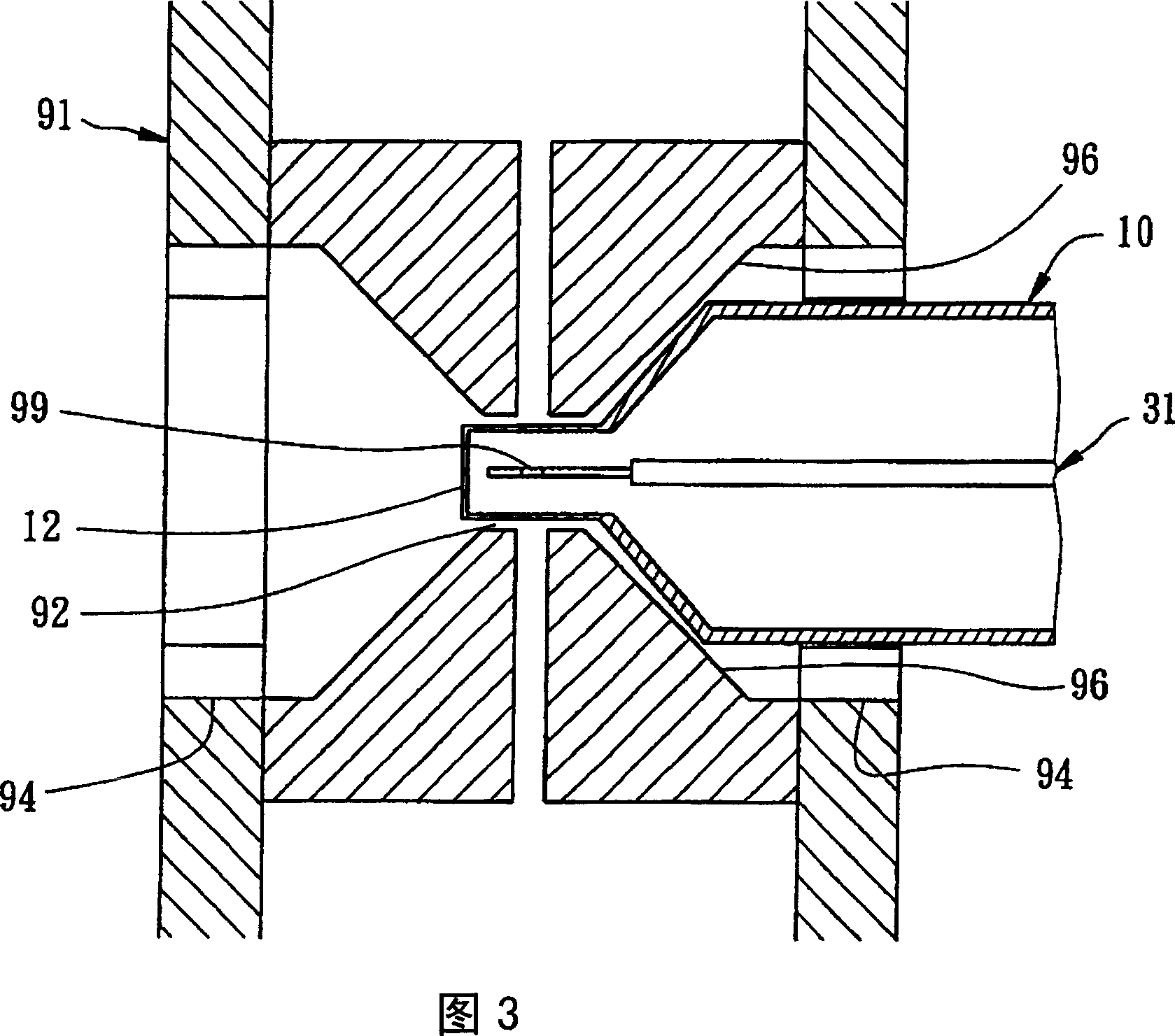

[0099] A housing 11, one side forms a flatter portion 12, the thickness of this flatter portion 12 is approximately less than the distance between the upper and lower diode blocks 96 in the sample chamber 92 (shown in Figure 3) (specimen chamber) of the electron microscope 91, Usually this distance is no more than one centimeter. There are several partitions 14 inside the casing 11, and an air chamber 16 is formed by partitioning the inside of the casing 11, and a buffer chamber 18 is respectively formed on the top and bottom of the outside of the air ch...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap