High-strength aluminium, magnesium alloy equi-temperature extrusion method based on numerical simulation

An isothermal extrusion and numerical simulation technology, applied in the field of material science, can solve the problems of large deformation, long time consumption, and grid distortion in the simulation process, so as to reduce the deformation of stretching and straightening, improve dimensional stability, extend the The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

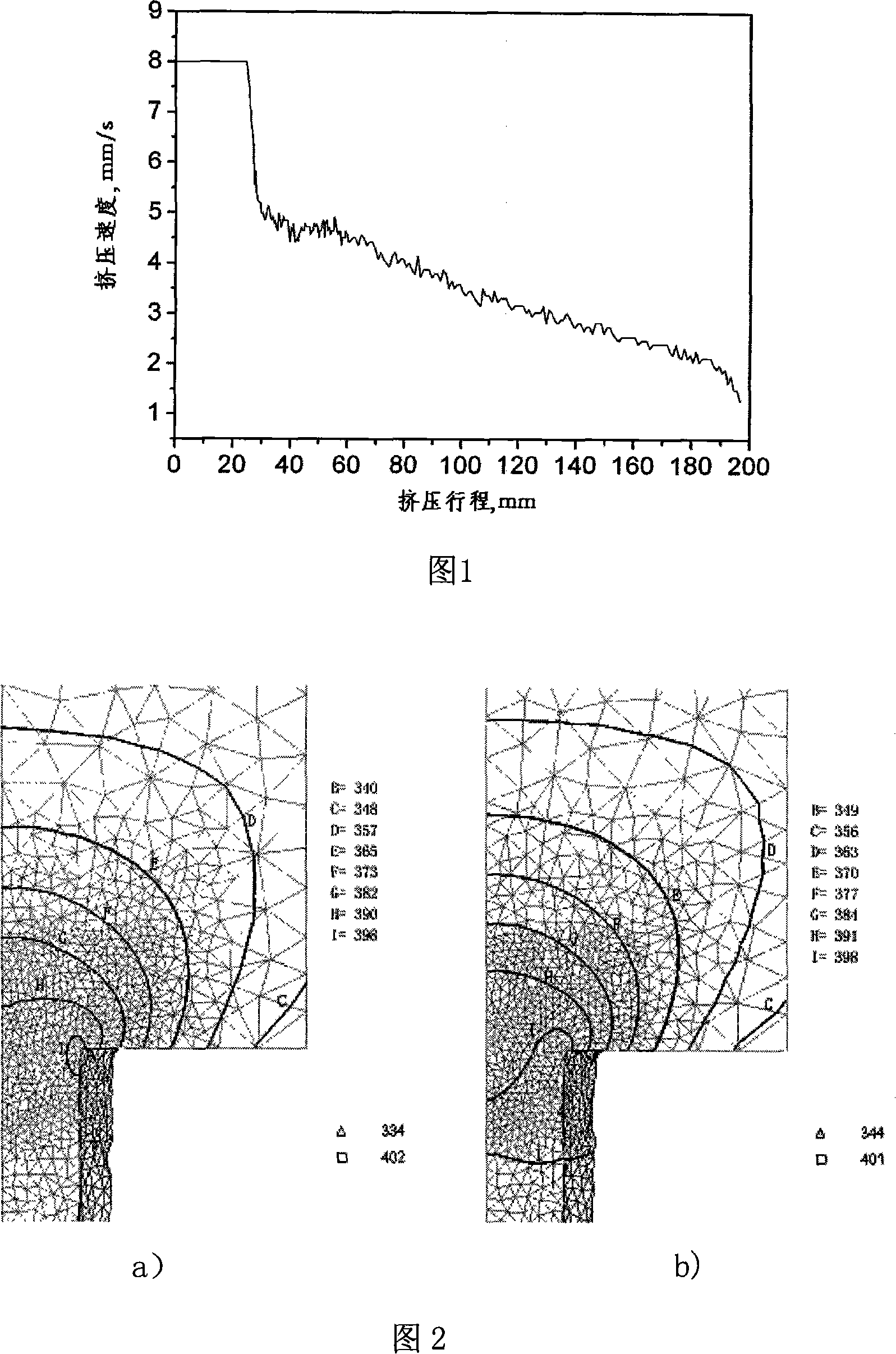

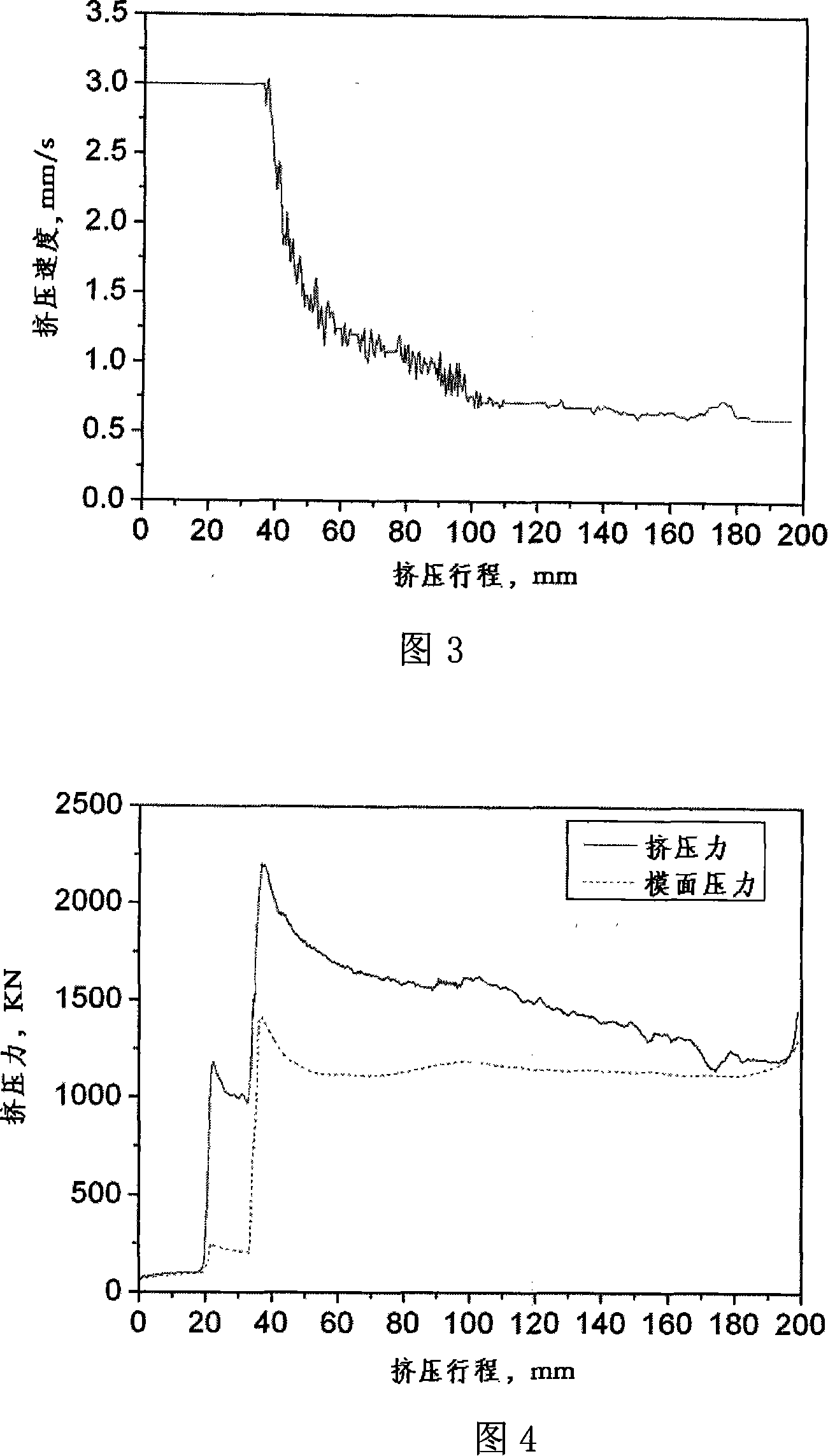

[0061] Isothermal Control Simulation of AZ31 Magnesium Alloy Cross Profile Flat Die Non-lubricated Extrusion Process. The maximum target temperature T0 of the selected workpiece is 400°C, the initial temperature of the billet is 350°C, and the temperature of the extrusion tools (extrusion barrel, extrusion pad and die) is set to 300°C. The initial extrusion speed was set at 8 mm / s. After 1000 steps of simulation calculation, the workpiece starts to extrude from the mold, and the maximum temperature of the workpiece rises rapidly to 401°C at step 1230, and PID control is started to be added at this time. In the early stage of control, due to large temperature changes, the sampling period should be as short as possible to improve control accuracy and control continuity. The period is 20 steps, corresponding to the displacement of the extrusion axis S = 0.4mm. When the extrusion reaches 3000 steps, the cycle is taken as 50 steps, which corresponds to the extrusion axis displacem...

Embodiment 2

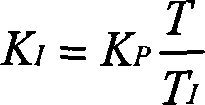

[0065] Isothermal Control Simulation of Extrusion Process of AZ31 Magnesium Alloy Hollow Square Tube with Split Die with Wall Thickness of 1.5 mm. Select the target temperature value at 4mm of the workpiece exit to be 400°C, the initial temperature of the billet is 350°C, the temperature of the extrusion tool (extrusion barrel, extrusion pad and die) is set to 300°C, and the initial extrusion speed is 3mm / s. When the simulation reaches step 1700, the workpiece is filled with the welding chamber, and the workpiece begins to extrude from the die, and the temperature of the workpiece rises rapidly. The cycle takes 100 steps, that is, the extrusion axis displacement S=0.2mm. The exit temperature of square tube extrusion is more sensitive to the change of extrusion speed, so the proportional parameter K P smaller. while using only K P When the value is controlled, there is still a static difference in the whole process, and the control cannot reach a steady state. So add inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com