Polymer material, its preparing method and use

A technology of polymer material and manufacturing method, which is applied in the field of mining polymer materials and its manufacturing, can solve problems such as affecting the strength and performance of materials, and achieve the effects of low production cost, simple process and no pollution to the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

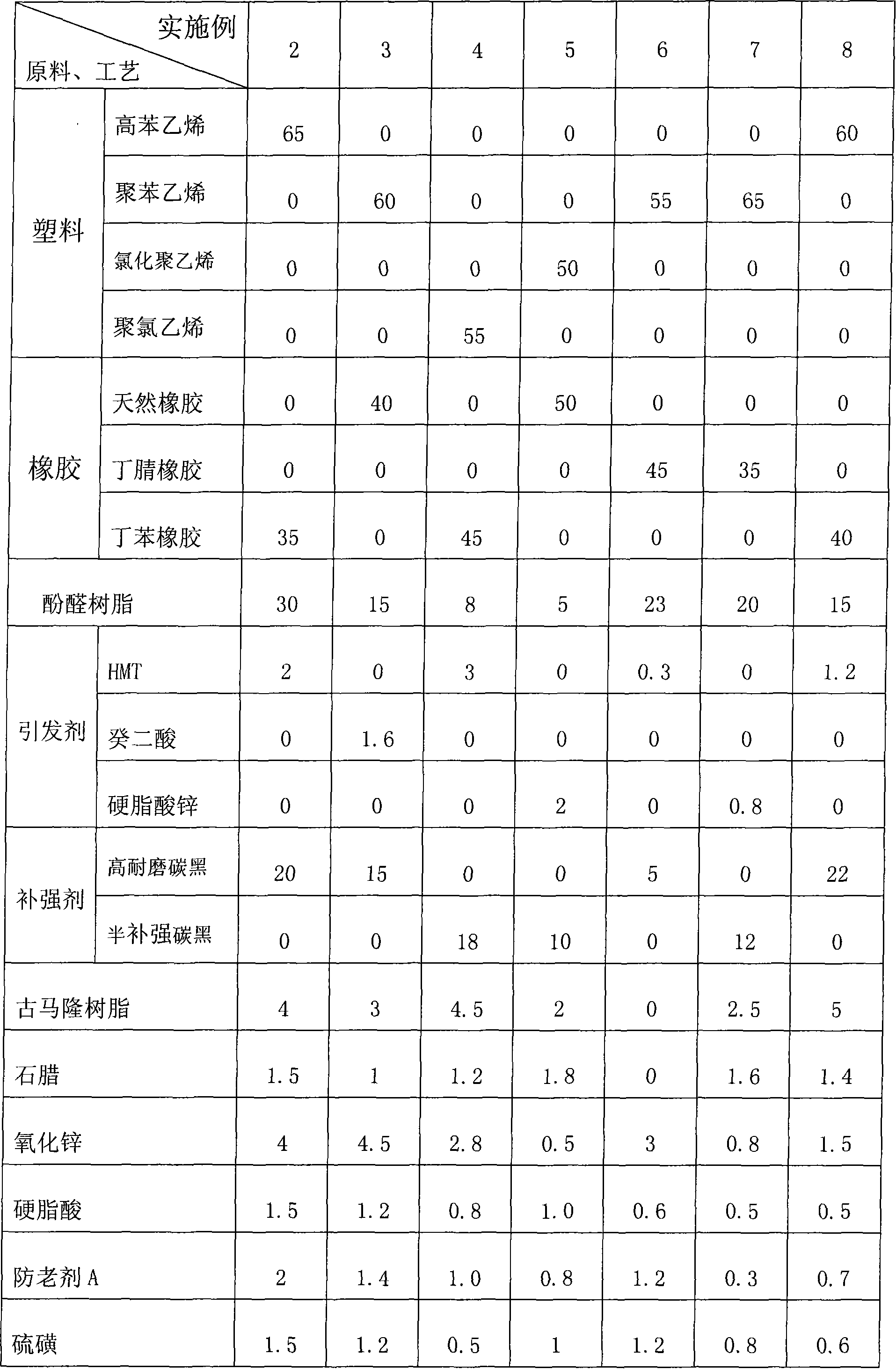

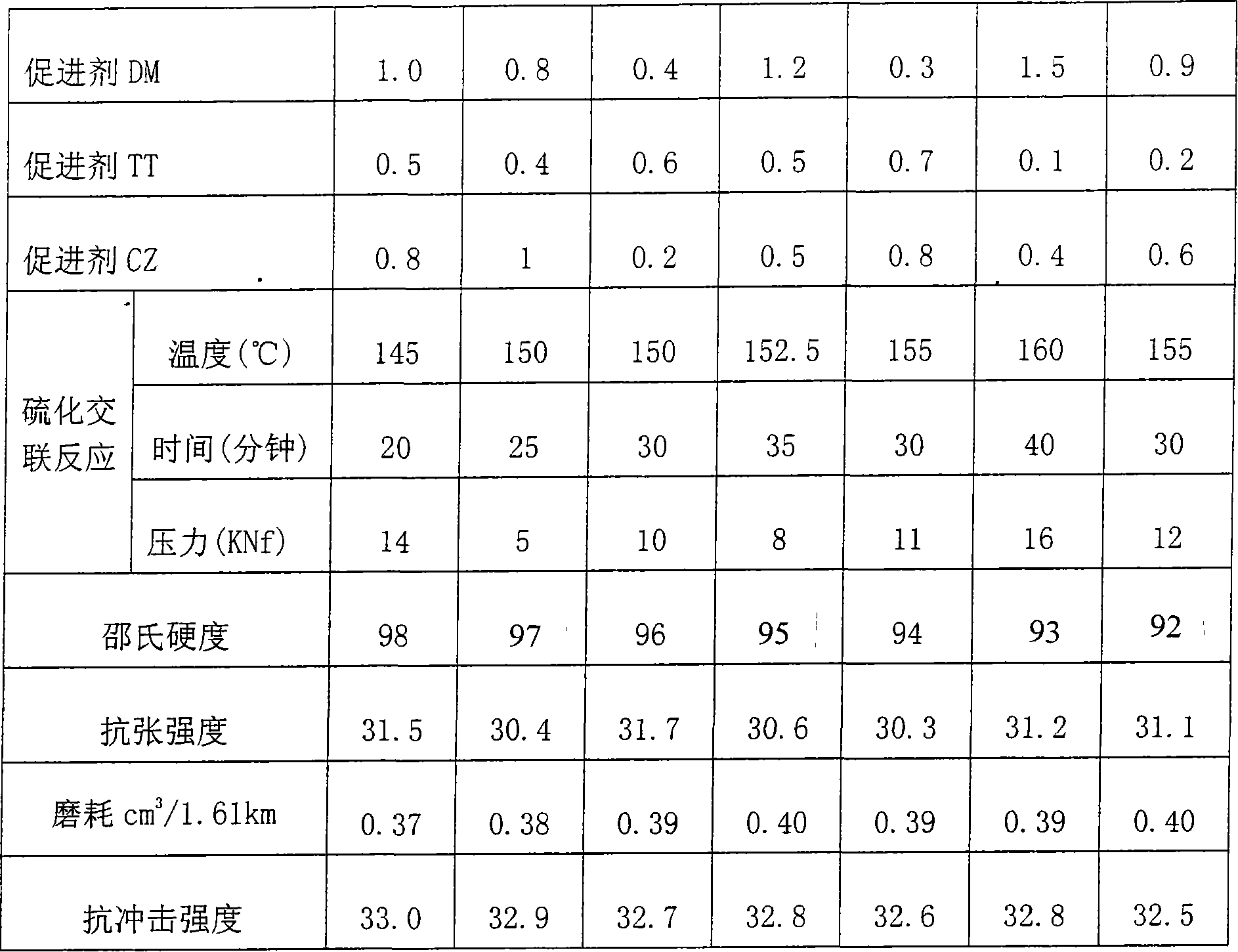

Examples

Embodiment 1

[0012] Embodiment 1: In the open mill that roll temperature is 140 ℃, add raw material successively by weight ratio: polystyrene 70, styrene-butadiene rubber 30, phenolic resin 40, initiator HMT (C 6 h 12 N 4 ) 3, zinc oxide 5, reinforcing agent high wear-resistant carbon black 25, anti-aging agent A 1.5, sulfur 1.5, accelerator DM 0.5, TT 0.7, CZ 1.2. Add the above raw materials one by one and knead them evenly, then remove the sheet, cool and park for 12 hours, then cut the mixture and put it into the vulcanizer for vulcanization and cross-linking reaction. When the vulcanization temperature is 155°C, the time is 25 minutes, and the pressure is 16KNf , the minimum wear of the obtained polymer material is 0.3cm 3 / 1.61km.

[0013] It can also be done using a mixer. In the above process, after adding the reinforcing agent and before adding the active agent zinc oxide, coumarone resin and paraffin wax with a weight ratio of 4 and 2 are added, so that the resulting polymer m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com