Combined piston of gas-oil spring

An oil-gas spring and combined technology, which is applied in the direction of springs, springs/shock absorbers, shock absorbers, etc., can solve problems such as waste, poor versatility, and difficulty in replacing valve group parts, so as to improve safety, Increased versatility and attenuation of vehicle body vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

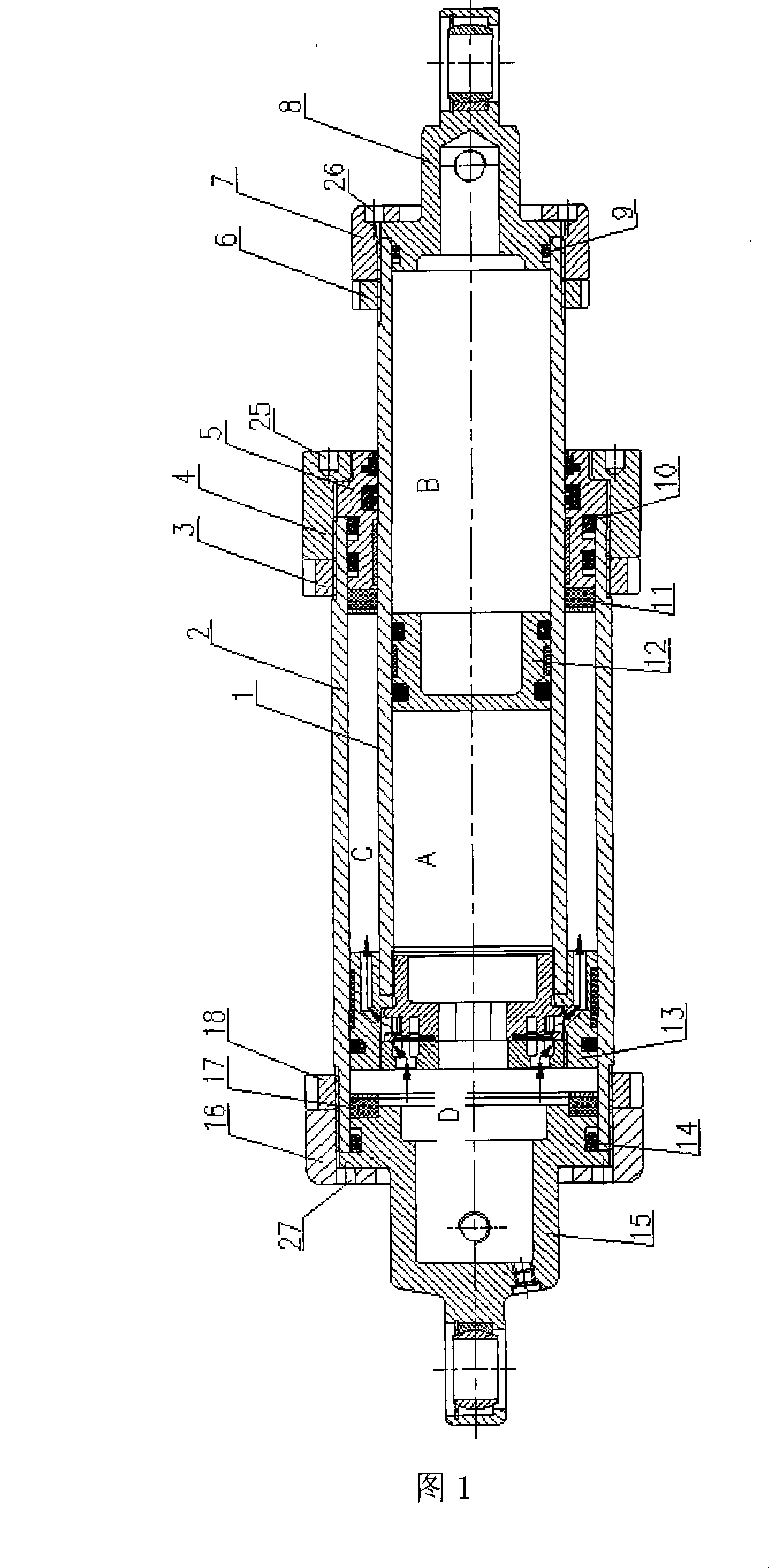

[0037] The following is a detailed description of the oil-pneumatic spring buffer device in conjunction with the accompanying drawings:

[0038] The hollow piston rod 1 is set in the cylinder barrel 2, the upper end of the piston rod 1 is equipped with a combined piston 13, and is connected together by threads, and the lower end is equipped with a lower joint assembly 8 to form a closed end, so as to pass through the connecting piece and The connecting arms of the axle are connected. The inner chamber of the piston rod is equipped with a floating piston 12, which divides the inner chamber of the piston rod into two chambers. The upper chamber is filled with oil, called the piston rod oil chamber A, and the lower chamber is filled with corresponding high-pressure inert oil chamber according to the static load of the vehicle. Gas, called piston rod cavity B. The upper end of the cylinder 2 is equipped with an upper joint assembly 15, which forms a closed end so as to be connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com