Method for laser in-situ repairing cavitation-vane gas turbine

An in-situ repair, steam turbine technology, applied in the direction of laser welding equipment, welding media, welding/welding/cutting items, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] This embodiment will be described in detail below in conjunction with the accompanying drawings.

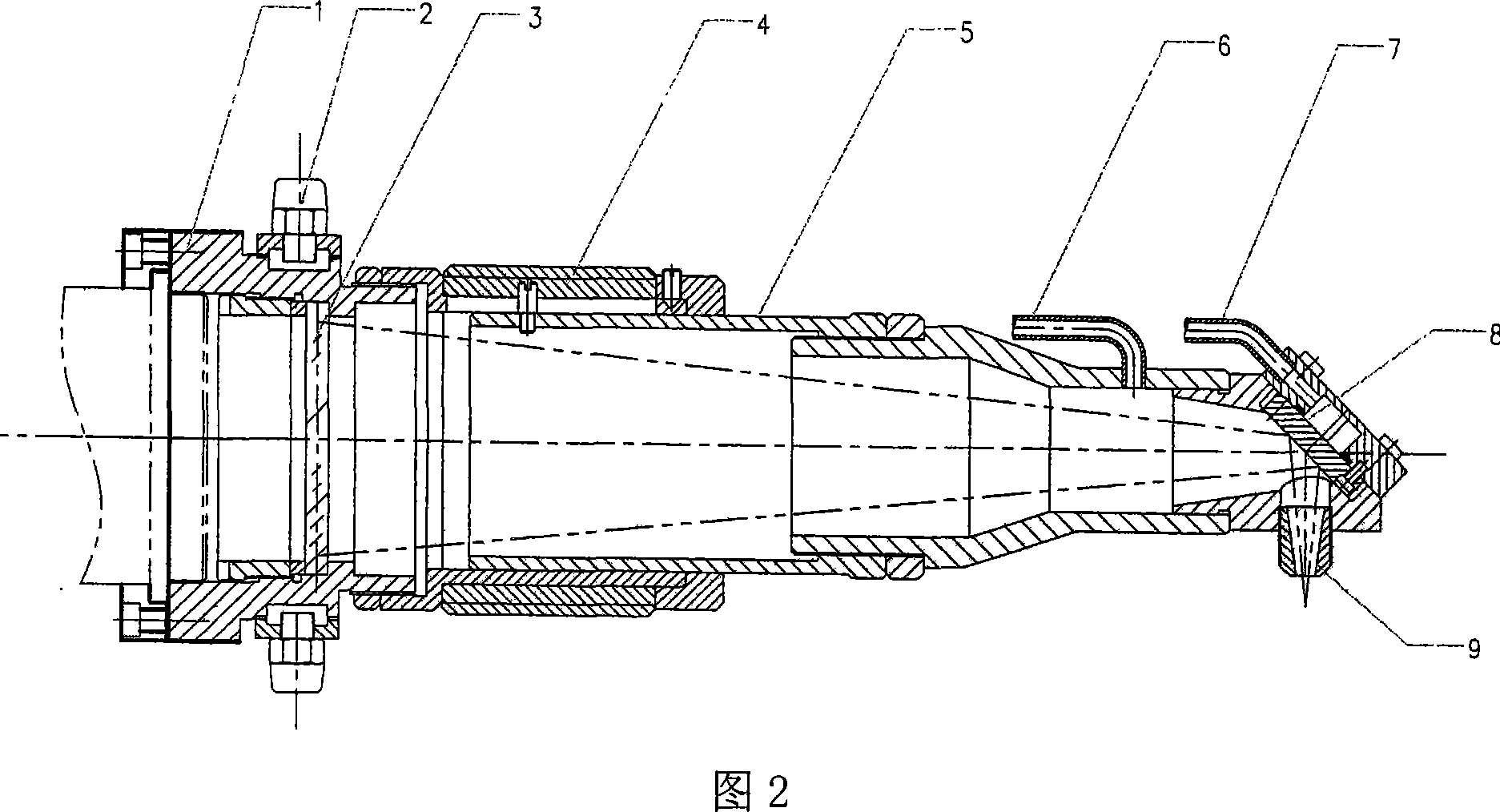

[0018] Because the distance between the blades of the steam turbine and the distance between the last stage of the steam turbine and the second last stage is very small, ordinary laser working heads cannot achieve cladding. Therefore, optical path turning and secondary focusing technologies are adopted in the laser working head to achieve The laser working head can reach the repair position, as shown in Figure 2. The laser working head is connected to the coupling output device of the laser through the connection seat 1, and the transmission mirror 3 made of ZnSe material is cooled through the cooling water circuit 2. The transmission mirror 3 realizes the initial convergence of the laser beam, and the length of the laser head is adjustable. Relying on the outer sleeve 4 and the inner sleeve 5 to achieve expansion and contraction, the protective gas 6 prevents impurities f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com