Biochar restorer for heavy-metal polluted marine deposits and preparation and restoration methods for biochar restorer

A marine sediment and repair method technology, applied in the field of biochar restoration agent and its preparation, can solve the problems of weak heavy metal adsorption capacity, marine heavy metal pollution, low biochar density, etc., and achieve the reduction of heavy metal bioavailability and abundance and the effect of increasing diversity and decreasing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

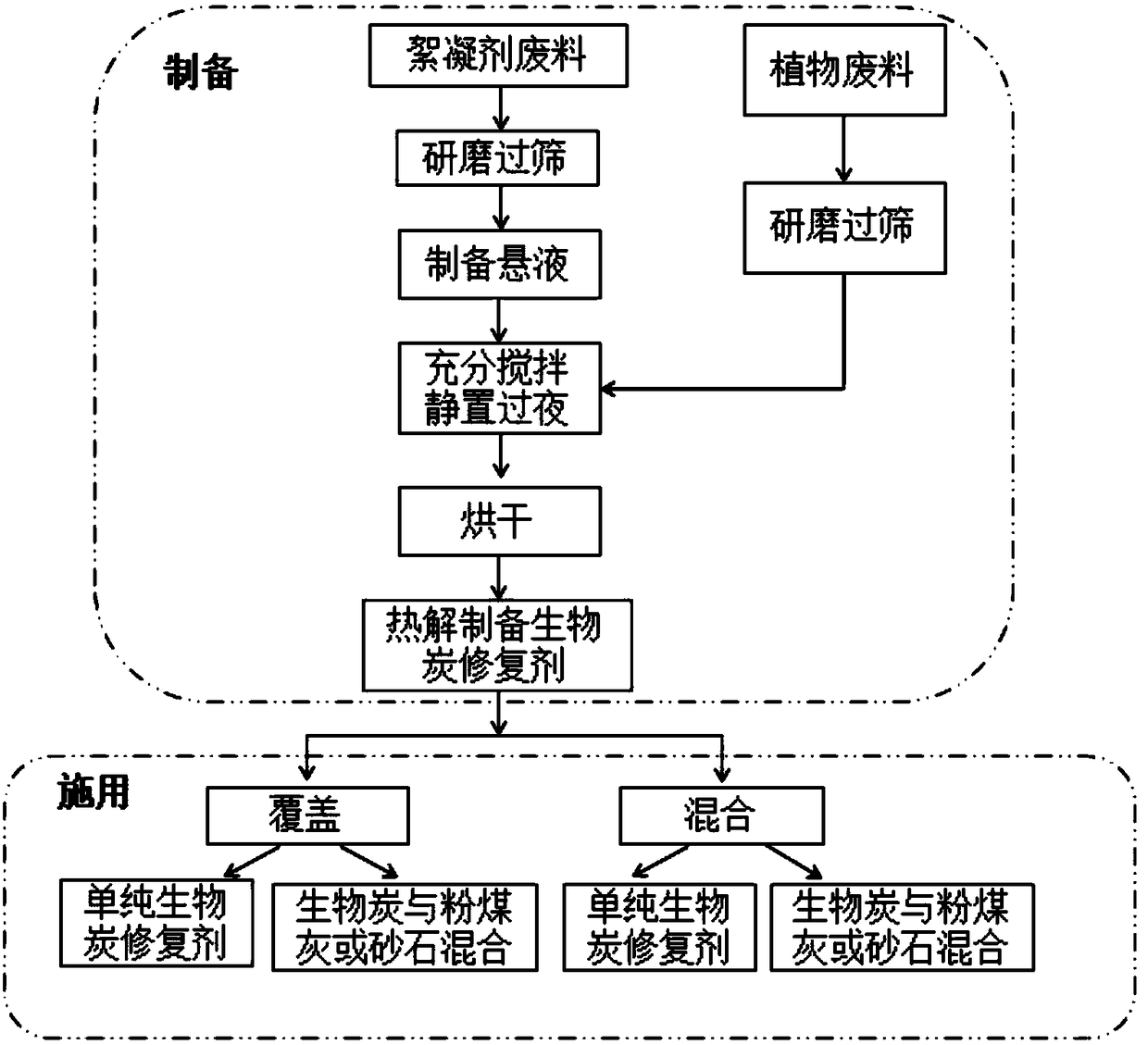

[0033] A preparation method of a biochar remediation agent for heavy metal-polluted marine deposits, comprising the steps of:

[0034] 1) Raw material treatment: dry the plant raw material at 60°C to constant weight, crush it through a 60-mesh sieve; dry the flocculant waste from sewage treatment, and crush it through a 60-mesh sieve; The above-mentioned plant raw materials were mixed evenly with the flocculant waste at a mass ratio of 1:1, and left to stand for 12 hours; the supernatant was removed, dried at 105°C to constant weight, and pulverized to obtain mixed raw materials;

[0035]2) Preparation of restorative agent: take the mixed raw materials and put them in a container, and carry out pyrolysis in a closed electric furnace, the pyrolysis atmosphere is nitrogen atmosphere, pyrolysis at 500°C, and the heating rate is 5°C·min -1 After the pyrolysis is over, keep the nitrogen atmosphere, cool to 25°C under the protection of nitrogen, and obtain the in-situ biochar remedi...

Embodiment 2

[0039] In this example, the preparation method described in Example 1 is used to prepare the biochar restoration agent, and the obtained biochar restoration agent is applied to the in-situ restoration of heavy metal polluted marine sediments:

[0040] The biochar remediation agent prepared by the above preparation method is applied in situ to heavy metal contaminated deposits, the application method is: directly cover the biochar remediation agent on the sediment polluted by heavy metals; the biochar remediation agent The coverage uses a crawler-type suspension jet machine to cover the biochar-based remediation agent on the surface of the heavy metal-contaminated sediment, and the coverage thickness is 10mm.

Embodiment 3

[0042] In this example, the preparation method described in Example 1 is used to prepare the biochar restoration agent, and the obtained biochar restoration agent is applied to the in-situ restoration of heavy metal polluted marine sediments:

[0043] The biochar remediation agent prepared by the above preparation method is applied in situ to the heavy metal polluted sediment, and the application method is: directly mixed with the heavy metal contaminated sediment; the mixing of the biochar remediation agent uses a ship-borne rotary tiller to The biochar-based remediation agent was mixed with heavy metal-polluted sediments to a mixing depth of 30 cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com