Hardened resin coating

A technology of hardening resin and coating, which is applied in the direction of coating and liquid coating device on the surface, etc. It can solve the problems of general products without structure, increase the complexity of the process, and reduce the yield of the process, so as to save process cost and structure Simple and effective for improving warpage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

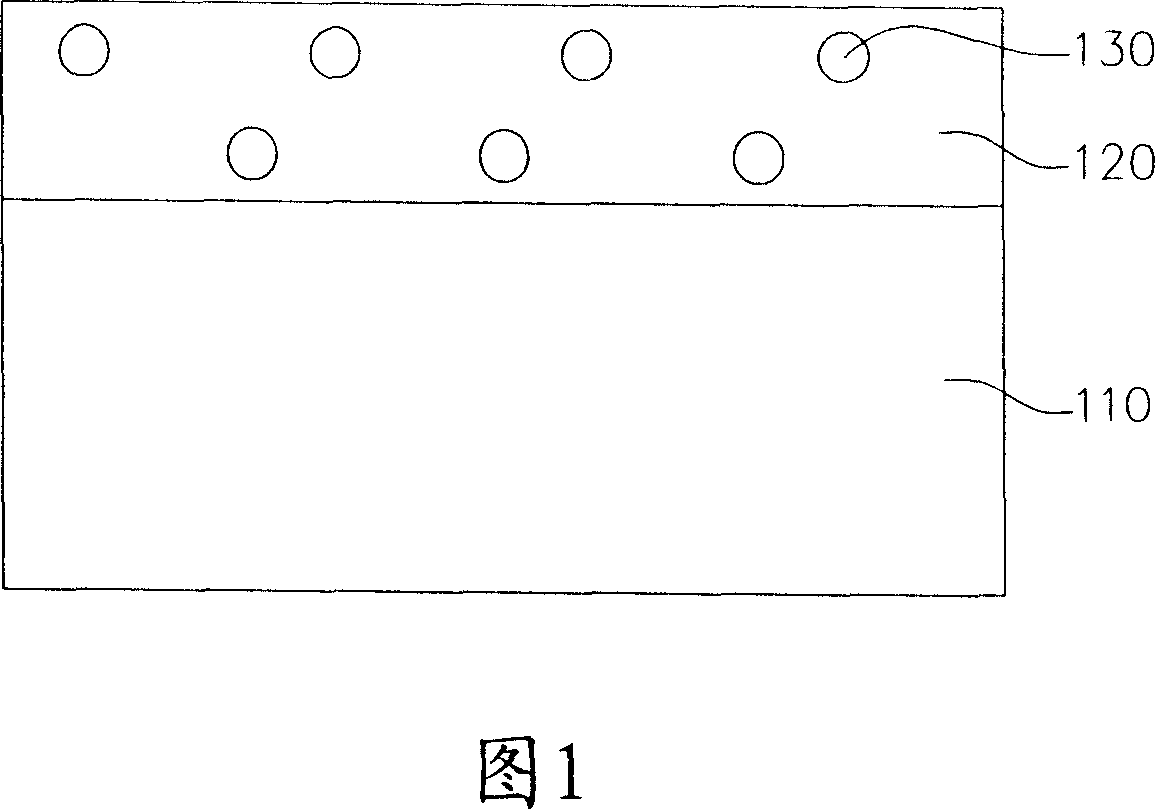

[0036] Please refer to FIG. 1 , which shows a schematic cross-sectional structure diagram of a cured resin coating according to a preferred embodiment of the present invention. In FIG. 1 , the resin coating 120 is located on the substrate 110 , and micron particles 130 with higher hardness are added in the resin coating 120 to increase the hardness of the resin coating 120 .

[0037] When the ultraviolet light irradiates the resin coating 120 to harden it, the resin coating 120 will undergo a cross-linking and hardening reaction. Since the cross-linking hardening reaction is fast, and the time is about 1-2 seconds, the resin coating 120 will cause stress concentration due to instantaneous shrinkage, and the resin coating 120 will warp. However, after micron particles 130 are added to the resin coating 120, the micron particles 130 can compensate for the shrinkage of the resin coating 120 during the cross-linking hardening process, reduce the warpage of the resin coating 120, a...

Embodiment 2

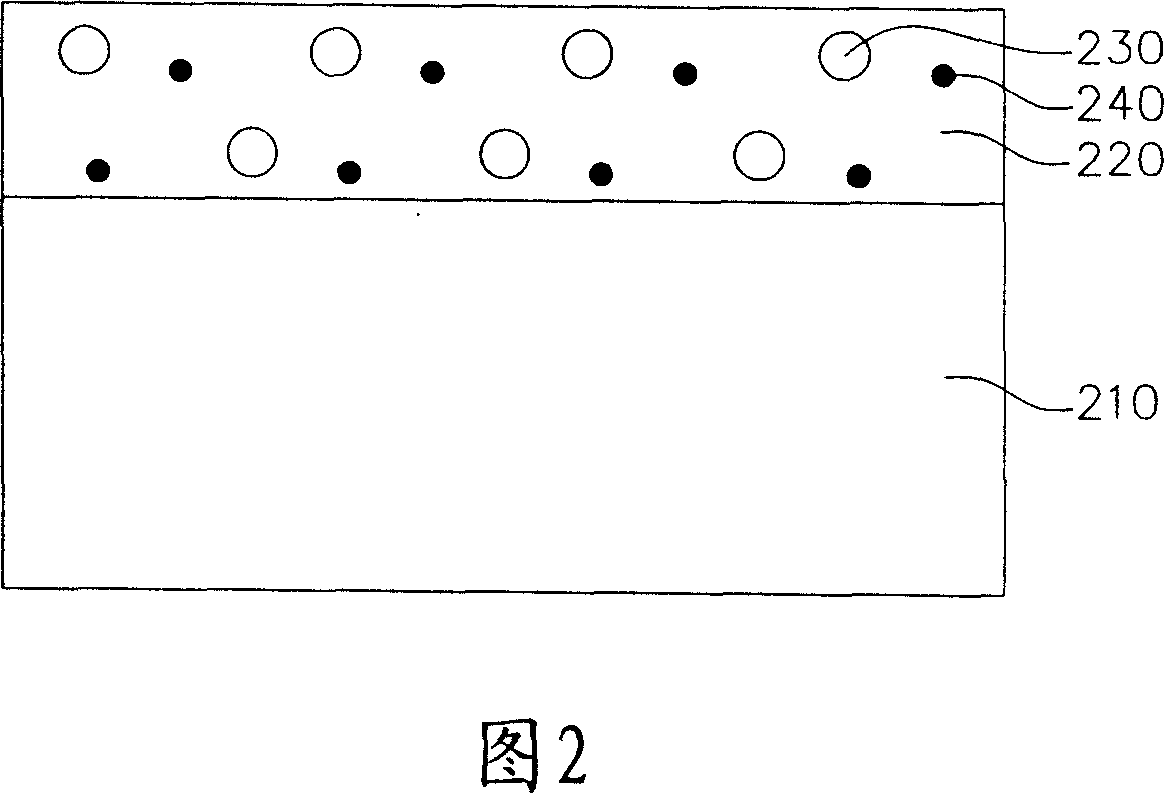

[0044] Please refer to FIG. 2 , which shows a schematic cross-sectional structure diagram of a cured resin coating according to another preferred embodiment of the present invention. In FIG. 2, the resin coating 220 is located on the base material 210. In addition to adding the micron particles 230 with higher hardness in the resin coating 220, nanoparticles 240 with higher hardness are added to further increase the hardness. The hardness of the resin coating 220 . The above-mentioned nanoparticles 240 have a particle size range of 5-100 nm, and their materials are preferably inorganic materials, such as silicon oxide, titanium oxide, or aluminum oxide. The materials of the base material 210 , the resin coating 220 and the micron particles 230 are the same as those described in the first embodiment, so they are not repeated here.

[0045] In this embodiment, the micro-particles 230 and the nanoparticles 240 are uniformly distributed in the resin coating 220 . If micron parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com