Liquid crystal display apparatus and method of restoring defected pixel

A liquid crystal display device, pixel electrode technology, applied in static indicators, nonlinear optics, instruments, etc., can solve problems such as defects, short-circuit bright spots or lines of pixel electrodes, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

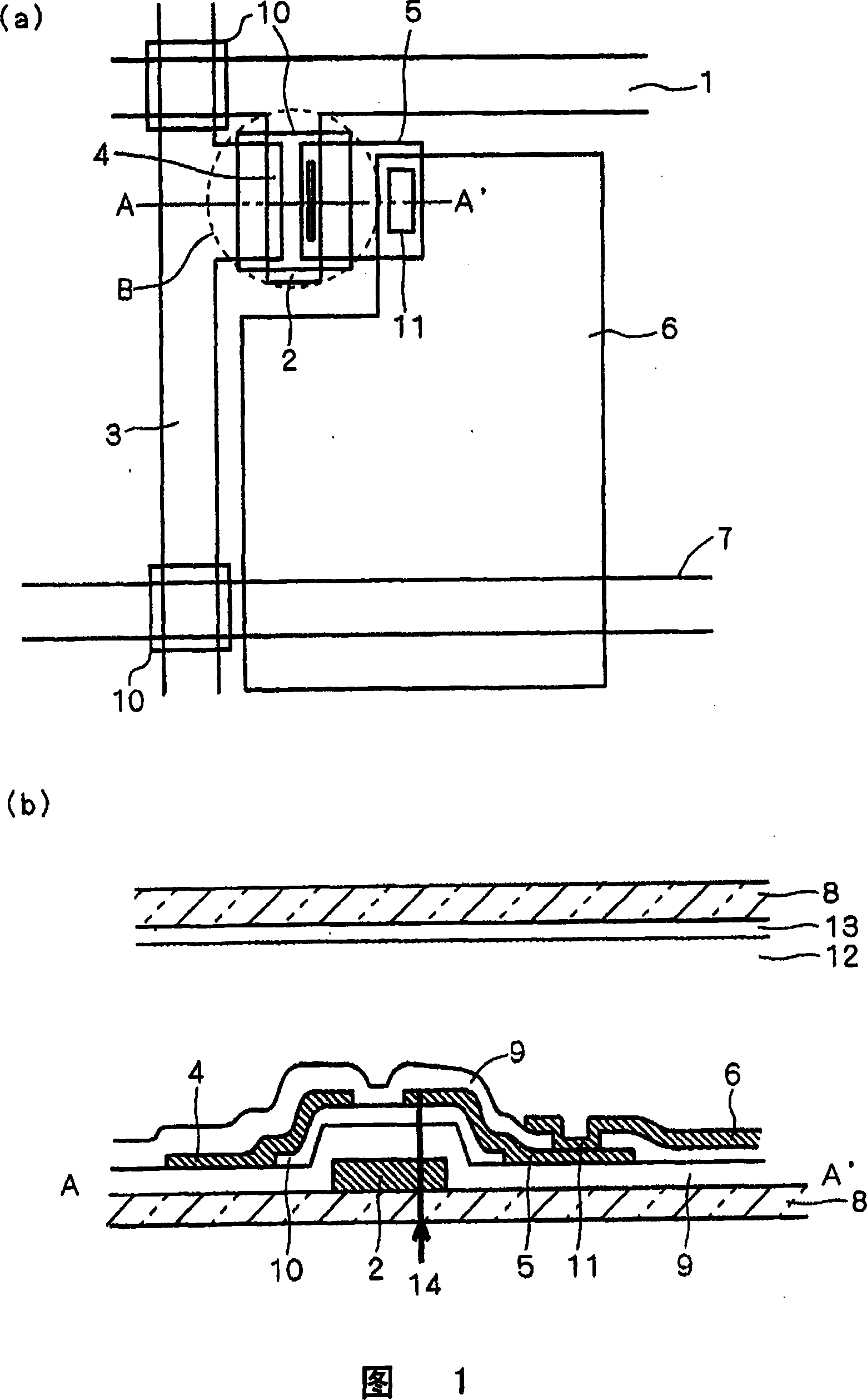

[0022] 1( a ), ( b ) show a plan view and a cross-sectional view of a liquid crystal display device according to this embodiment. Wherein, Fig. 1(a) shows a plan view of a pixel portion of the array substrate, and Fig. 1(b) shows a cross-sectional view along A-A' of Fig. 1(a). The liquid crystal display device of this embodiment has a structure in which pixels are arranged in a matrix, and each pixel is driven by a thin film transistor (TFT) which is a thin film active element.

[0023] In the liquid crystal display device of this embodiment, as shown in FIGS. An insulating film 9 is provided in two layers, and an amorphous silicon (a-Si) film 10 as a semiconductor active film is provided in a third layer. Furthermore, in the liquid crystal display device of this embodiment, the source wiring 3, the source electrode 4, and the drain electrode 5 are provided in the fourth layer, the insulating film 9 is provided in the fifth layer, and finally the pixel electrode 6 is provided...

Embodiment approach 2

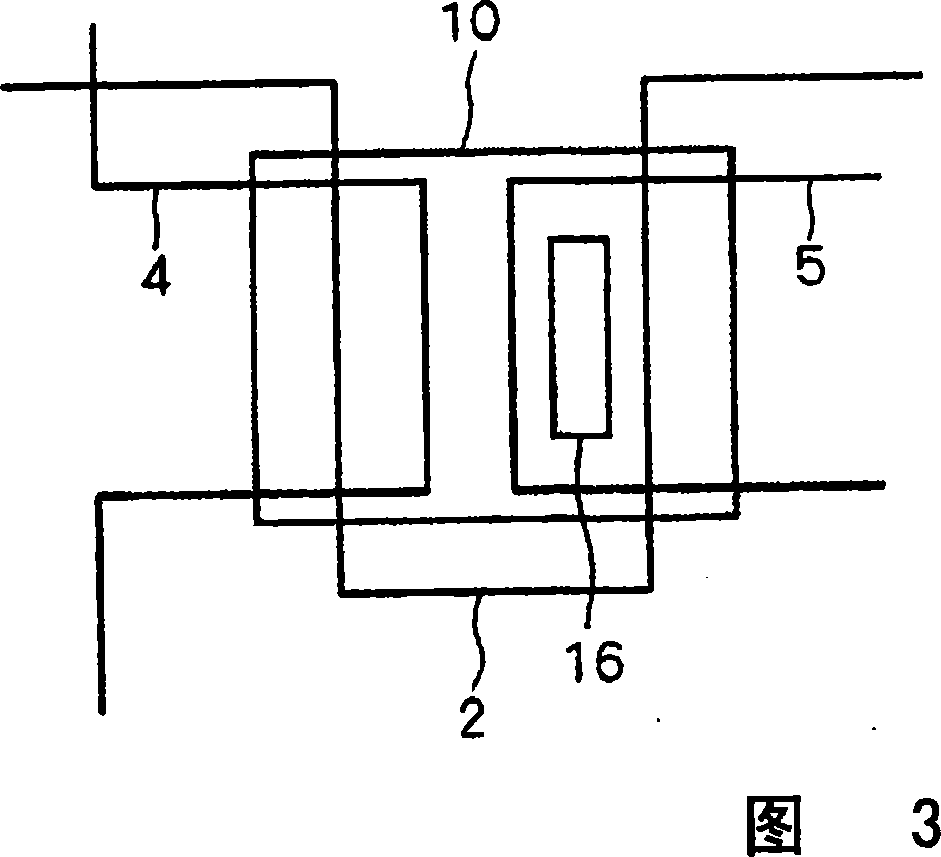

[0034] FIG. 3 is an enlarged view showing a TFT of the liquid crystal display device of the present embodiment. In FIG. 3 , a hole 16 is provided on the drain electrode 5 at a position where the gate electrode 2 and the drain electrode 5 planarly overlap each other. The hole 16 provided may have any shape as long as it is located at a position where the gate electrode 2 and the drain electrode 5 planarly overlap each other. In addition, in the present embodiment, the hole 15 is not provided on the gate electrode 2 .

[0035] In addition, in this embodiment, since the hole 15 is not opened in the gate electrode 2, the position of the hole 16 provided in the drain electrode 5 cannot be confirmed from the glass substrate side. Therefore, when a bright spot defect caused by a malfunction of the TFT occurs, as shown in FIG. The hole 16 is used to determine the irradiation position of the laser light 14 .

[0036] However, compared with the case where the gate electrode 2 and the...

Embodiment approach 3

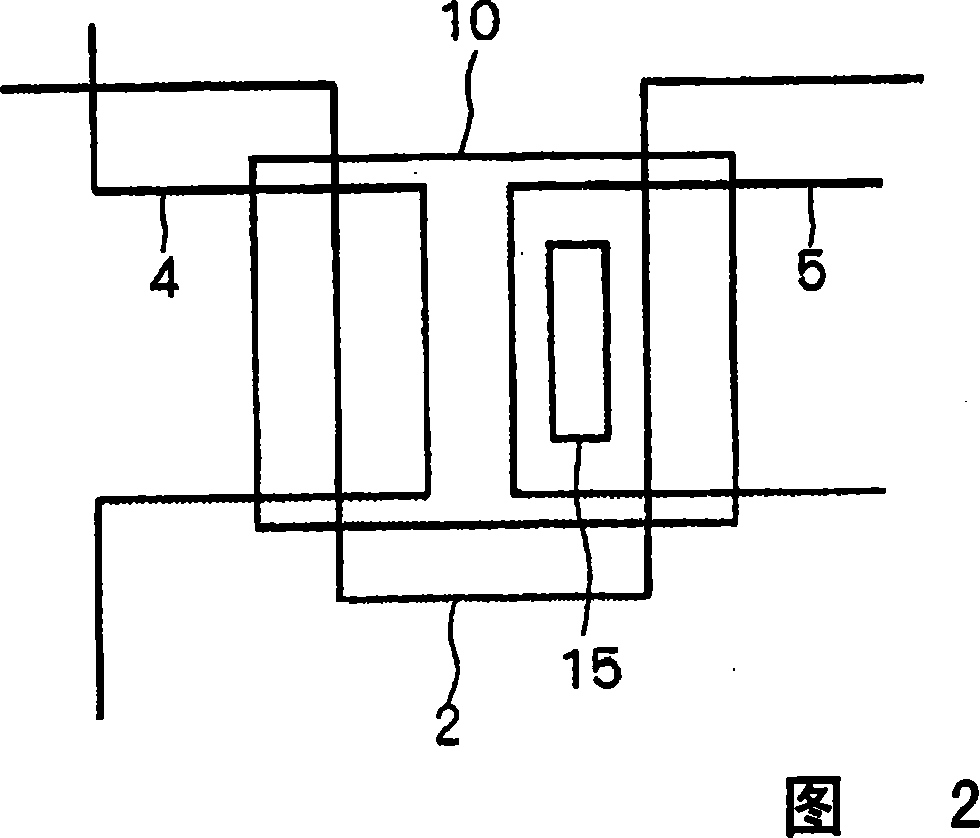

[0039] The structure of the liquid crystal display device of Embodiment 1 is such that, as shown in FIG. 2 , a hole 15 is provided in the gate electrode 2 at a position where the gate electrode 2 and the drain electrode 5 planarly overlap each other. On the other hand, the structure of the liquid crystal display device according to the second embodiment is such that, as shown in FIG. 3 , hole 16 is provided in drain electrode 5 at a position where gate electrode 2 and drain electrode 5 planarly overlap each other.

[0040] The liquid crystal display device of this embodiment employs a combination of Embodiment 1 and Embodiment 2. That is, the structure of the liquid crystal display device of the present embodiment is: the hole 15 is provided on the gate electrode 2 at the position where the gate electrode 2 and the drain electrode 5 planarly overlap each other, and the hole 15 is provided at the position where the gate electrode 2 and the drain electrode 5 planarly overlap each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com