Nitride-based semiconductor light emitting diode

A nitride semiconductor, nitride-based technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of reducing the reliability and yield of nitride-based semiconductor LEDs, and unstable characteristics of nitride-based semiconductor LEDs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0039] First, a nitride-based semiconductor LED according to a first embodiment of the present invention will be described with reference to FIGS. 4 and 5 .

[0040] 4 is a plan view showing the structure of a nitride-based semiconductor LED according to a first embodiment of the present invention, and FIG. 5 is a cross-sectional view taken along line V-V' of FIG. 4 .

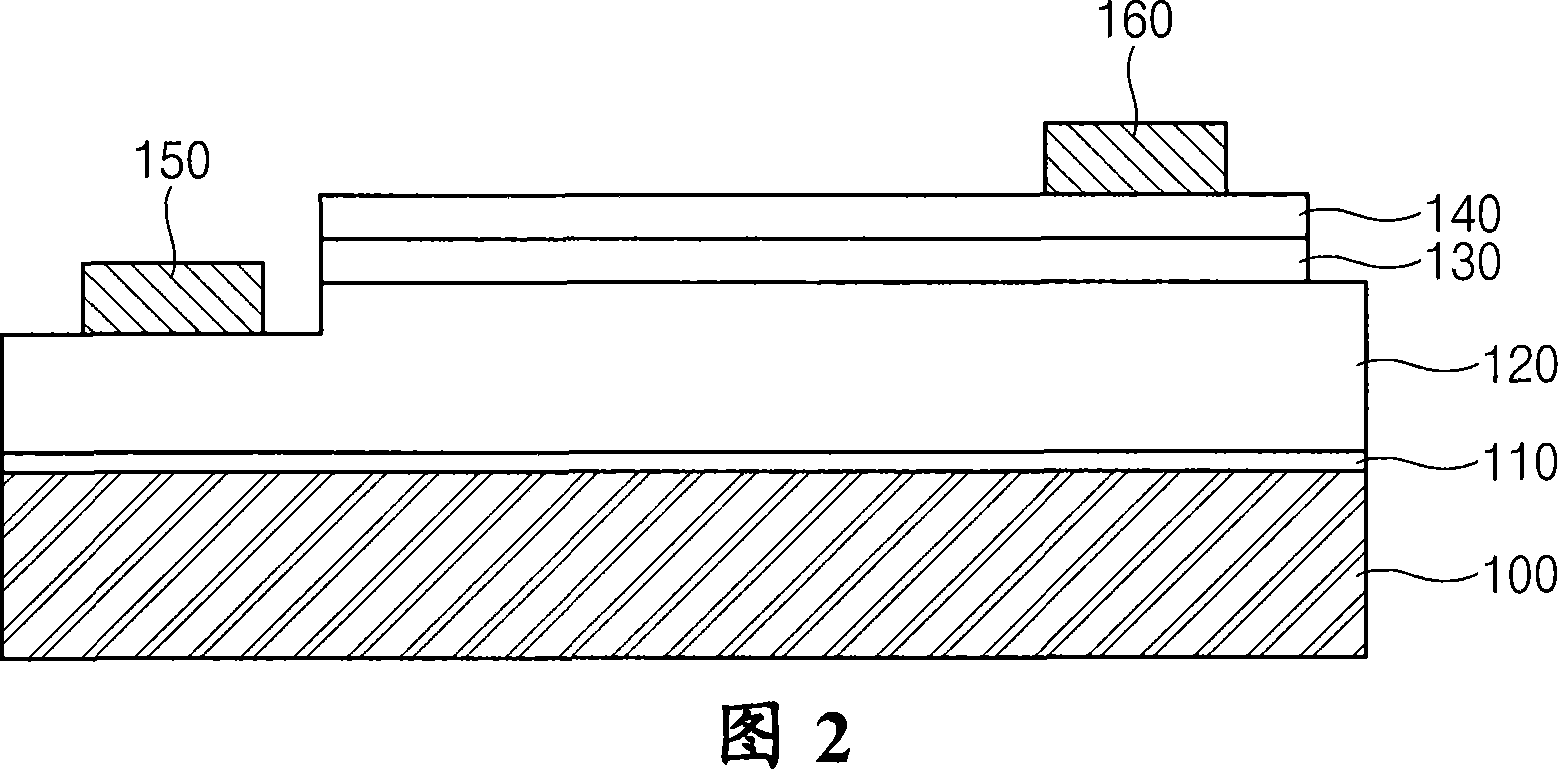

[0041] As shown in FIG. 4 and FIG. 5, the nitride-based semiconductor LED according to the first embodiment of the present invention includes an optically transparent substrate 100 and a light emitting structure, wherein a buffer layer 110, an n-type nitride semiconductor layer 120, an active layer 130 , and a p-type nitride semiconductor layer 140 are sequentially laminated on the substrate 100 .

[0042] The substrate 100 may be a heterogeneous substrate, such as a sapphire substrate and a silicon carbide (SiC) substrate, or a homogeneous substrate, such as a nitride substrate, which is suitable for growing a...

no. 2 example

[0059] Next, a nitride-based semiconductor LED according to a second embodiment of the present invention will be described in detail with reference to FIG. 7 . However, descriptions of components in the second embodiment that are the same as those in the first embodiment will be omitted.

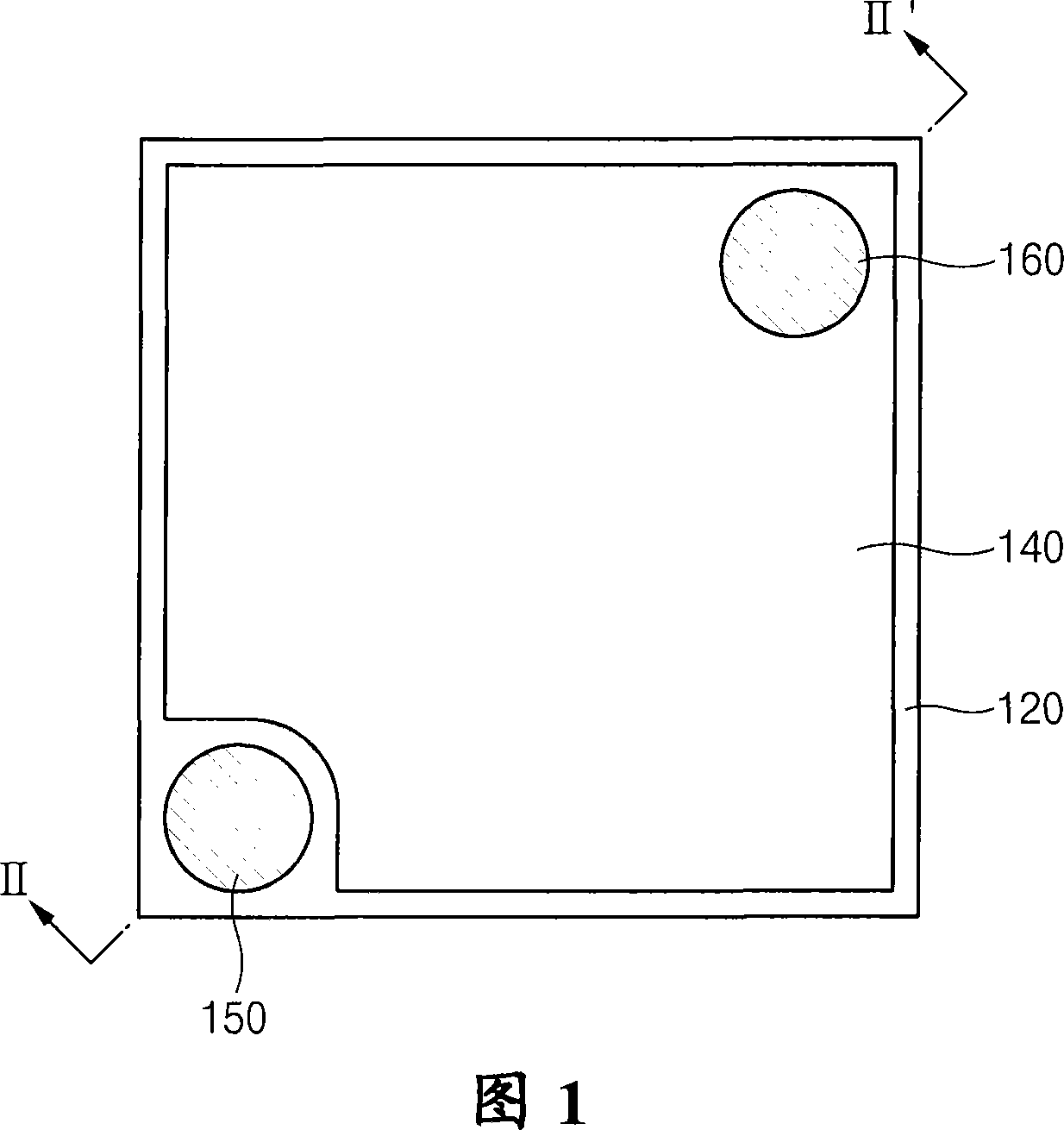

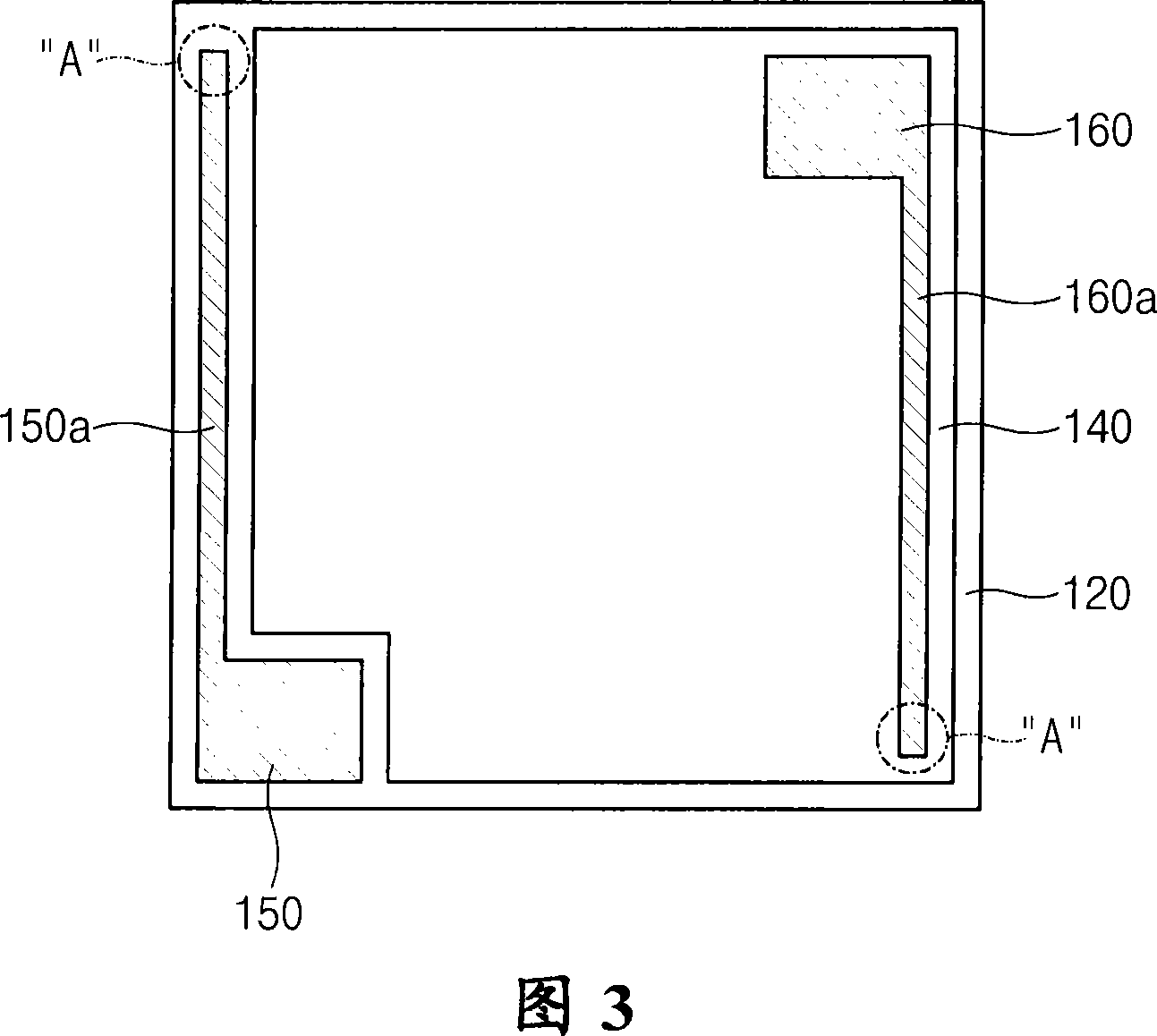

[0060] Fig. 7 is a plan view showing the structure of a nitride-based semiconductor LED according to a second embodiment.

[0061] As shown in FIG. 7, the nitride-based semiconductor LED according to the second embodiment has almost the same structure as that of the nitride-based semiconductor LED according to the first embodiment. However, in the second embodiment, the n-electrode 150 and the p-electrode 160 are formed in a hemispherical shape instead of a rectangular shape. In addition, two p-type branch electrodes 160a are arranged in a finger shape so that the p-type branch electrodes 160a are parallel to each other.

[0062] Similar to the first embodiment, n-type and p-type ESD pads ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com