High strength hot rolled steel sheet having excellent stretch flangeability and its production method

A hot-rolled steel plate, tensile strength technology, applied in the field of high-strength hot-rolled steel plate, can solve the problems of poor shape freezing, increase the heating temperature of the billet, etc., and achieve excellent formability, high strength, and good stretch flangeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

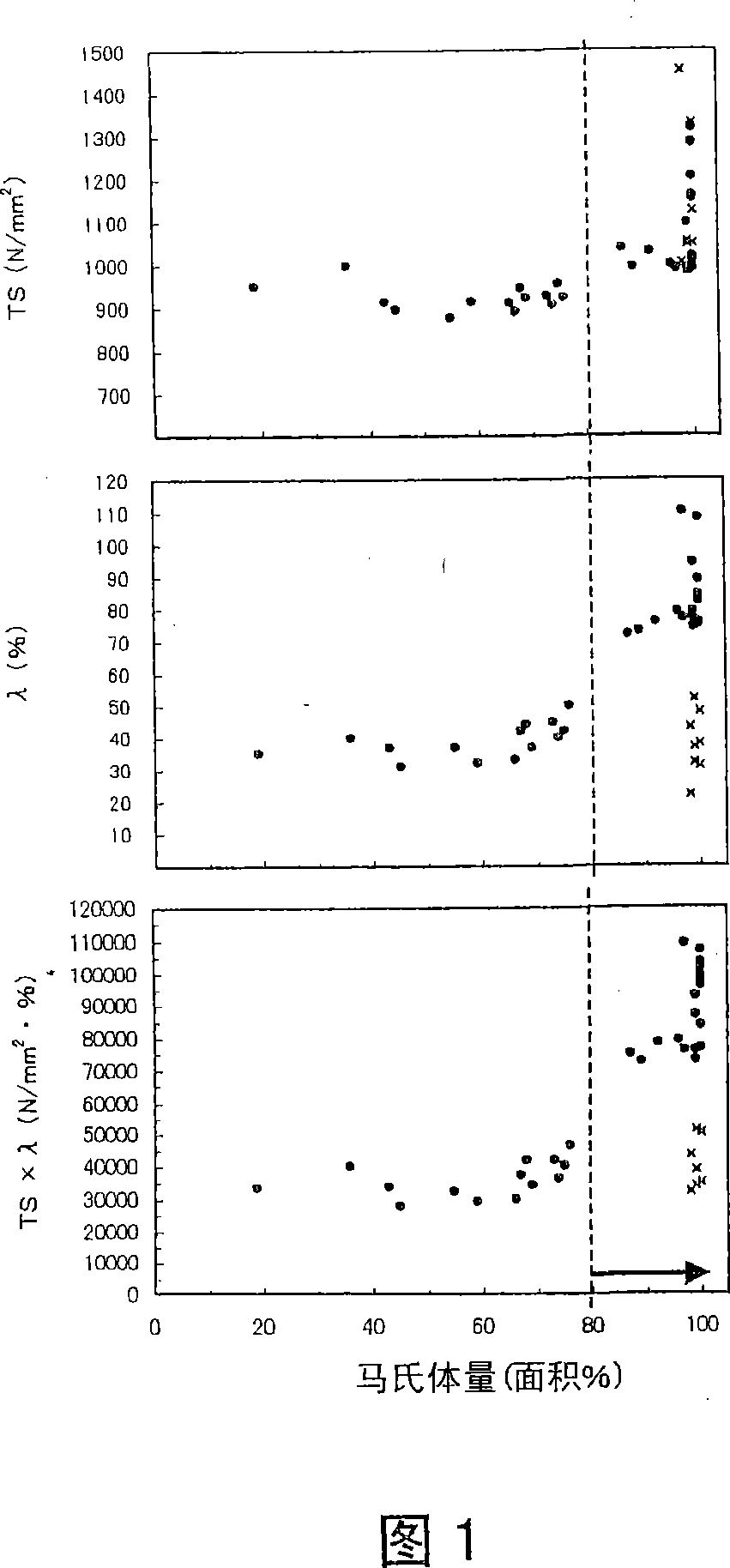

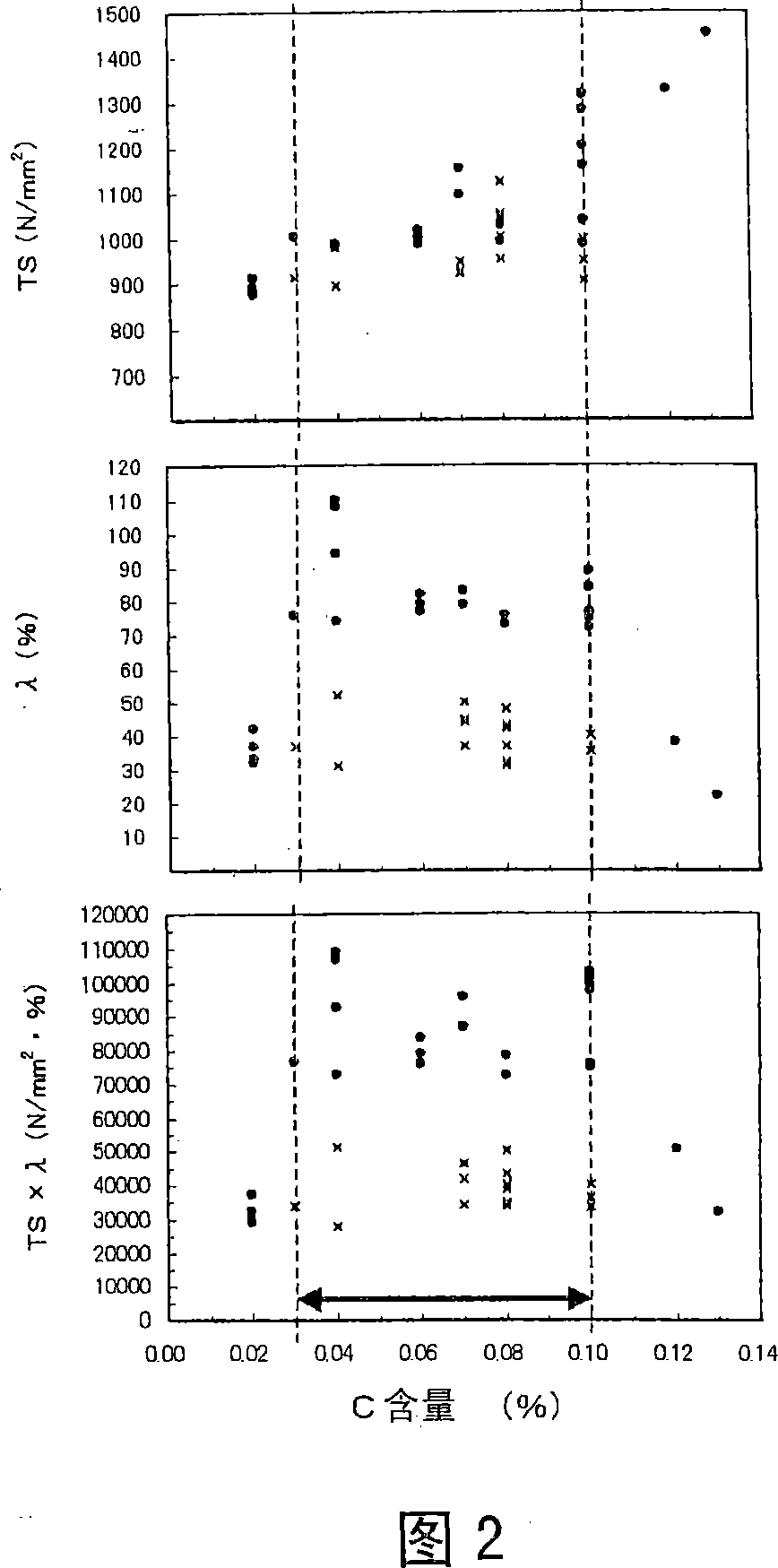

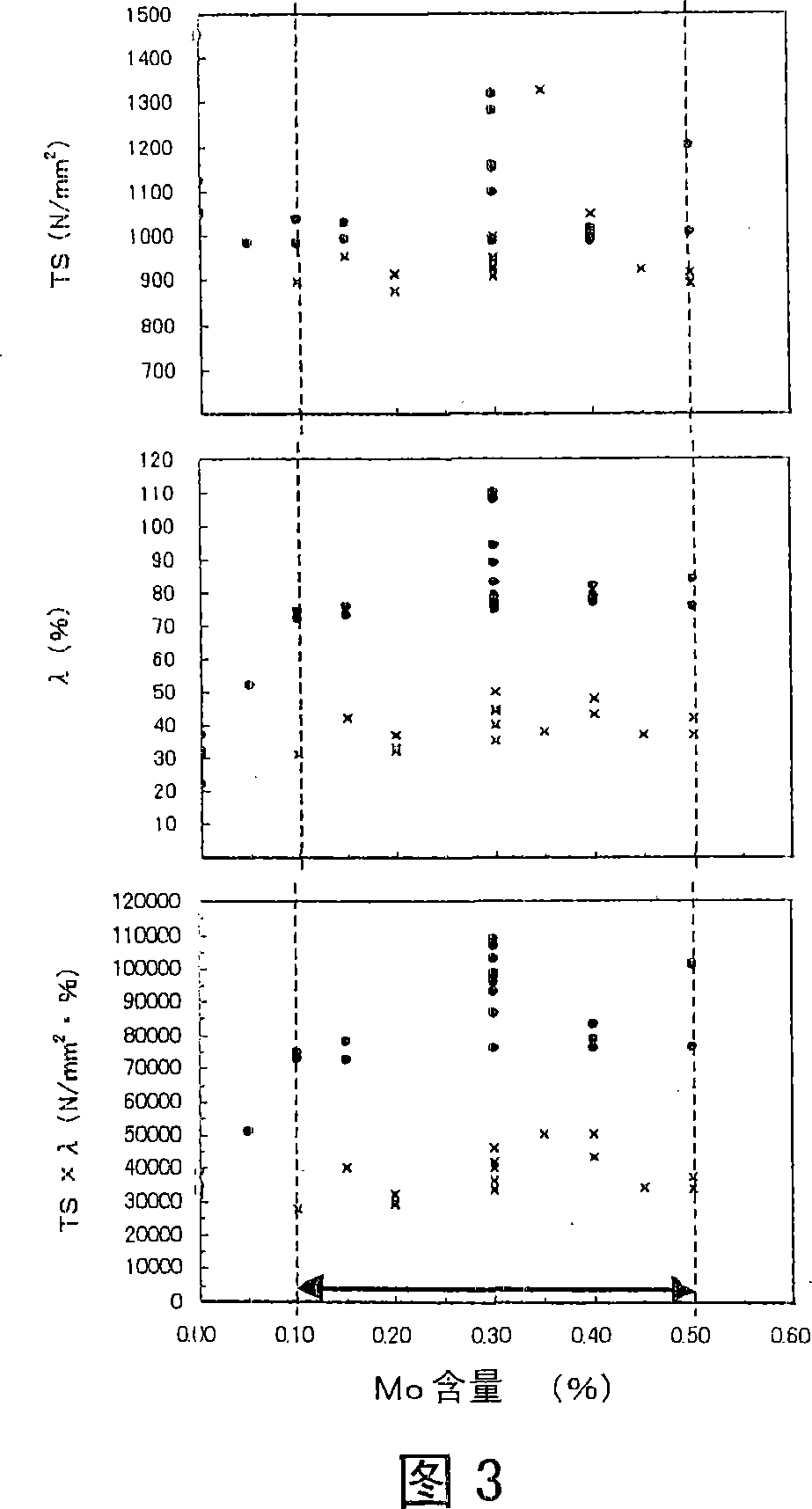

[0063] The steel materials with the composition shown in Table 1 were melted by vacuum melting method and then cast, and the obtained slabs were hot-rolled under the conditions shown in Tables 2 and 3 to obtain hot-rolled steel sheets. The metal structure of the obtained hot-rolled steel sheet was confirmed by the following method, and its physical properties were measured by the following method. The results are shown in Tables 2 and 3.

[0064] [metal organization]

[0065] Microstructure identification method: The longitudinal section of the steel plate is subjected to レペラ-(LePera) corrosion to form a state where the martensite phase and other phases can be visually distinguished. Next, after the C vapor deposition process was performed using the vacuum vapor deposition apparatus "JEE-4X" manufactured by JEOL Ltd., the structure was observed using the EPMA "JXA-8100" manufactured by JEOL Ltd. (magnification: 1000 times), based on which NIRECO The image analysis device "LUZ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com