Honeycombed light wall plate manufacturing technique

A production process and honeycomb technology, which is applied in the field of improved structure of honeycomb light wall panels, and can solve the problems of easy perforation, difficulty in decoration, reduction of wall panel strength or sound insulation effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 (inner wall panel)

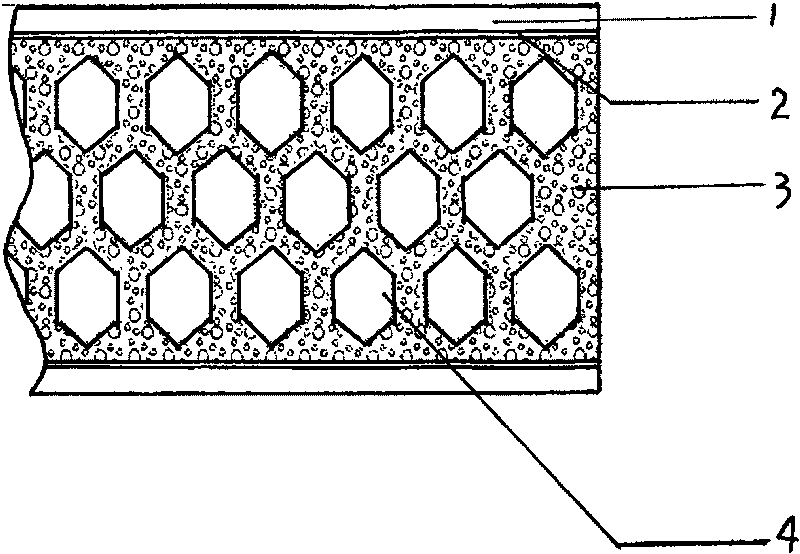

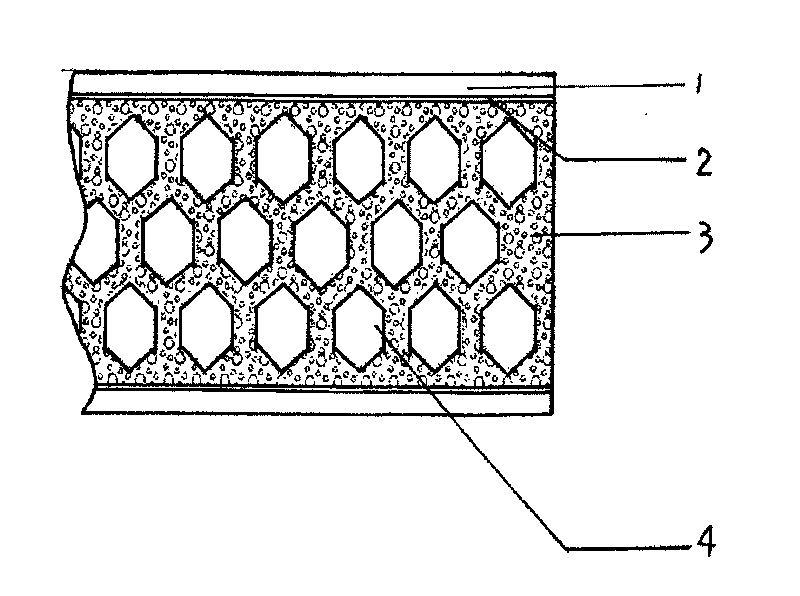

[0027] See attached figure 1 As shown, the surface layer 1 of the gypsum material is provided on both sides of the honeycomb light wallboard, and the surfaces of the surface layer 1 on both sides are smooth and smooth, and no secondary plastering surface is required; the inside of the surface layer 1 is sequentially provided with The reinforcement layer 2 and the composite material layer 3 used for fillers; in order to reduce the weight of the wallboard, it has strength, and a honeycomb shape formed by honeycomb holes 4 is interlacedly distributed inside the composite material layer 3 . Closed ring ribs are formed between adjacent honeycomb holes 4, which have large volume, small amount of consumables, not easy to deform, and strong resistance to compression and bending. It uses honeycomb bionics to improve the strength / quality ratio of wall panels important evidence is provided.

[0028] The process steps of the wall panel:

[0029]...

Embodiment 2

[0037] Embodiment 2 (external wall panel)

[0038] The difference between this embodiment 2 and embodiment 1 is that the gypsum material is changed to a sulphoaluminate cement material in steps 2, 4, and 7; the volume ratio of its sulphoaluminate cement to polyphenylene particles is also 3:7; Other process steps are the same as in Example 1, so they are omitted.

[0039] In the above two embodiments, the mentioned staggered holes inside the wall panels are preferably honeycomb holes; depending on the actual application, they may also be staggered circular holes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com