Peg-pole-prestress supporting system and construction method thereof

A support system and construction method technology, applied in pillars/brackets, sheet pile walls, earthwork drilling and mining, etc., can solve the problem of shield machine efficiency not being fully utilized, and achieve strong ability to control segment deformation and easy monitoring , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

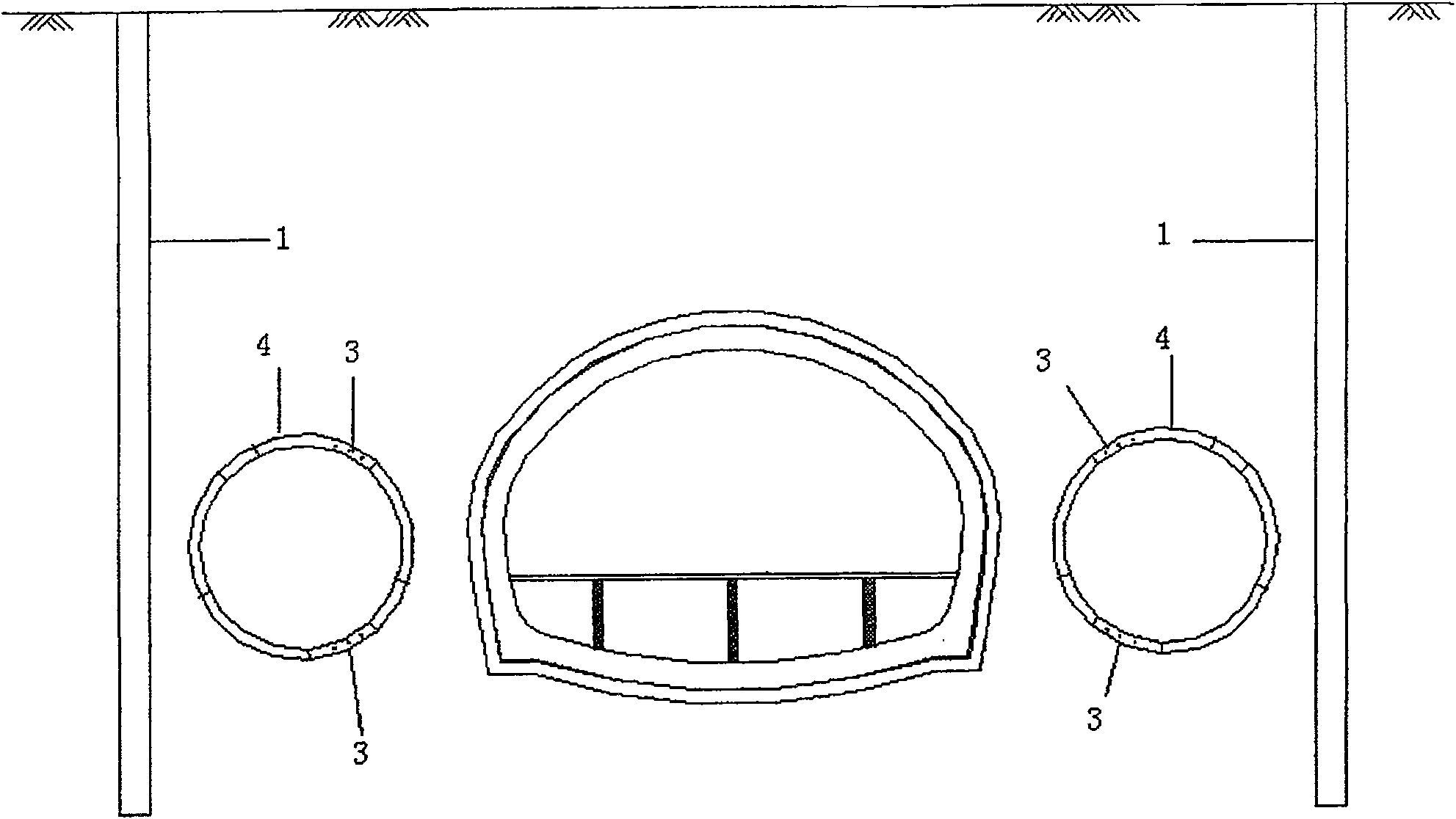

[0018] Embodiment 1: as figure 1 , as shown in 2,

[0019] A pile-column-prestressed support system construction method has the following steps:

[0020] 1) Set the distance from the pile row 1 to the shield tunnel and the diameter and spacing of the pile row 1;

[0021] Set row piles 1 near the outside of the shield tunnel with appropriate diameter and spacing to achieve the effect of isolating the soil.

[0022] 2) The temporary support column 2 erected in the shield tunnel segment 4 ensures the strength and stability of the temporary support column 2 of the shield tunnel;

[0023] After removing part of the shield tunnel segment 4 at the position of the transverse channel 7, the shield tunnel structure under the force of the entire ring segment 4 becomes an open-shaped unstable structure, which may produce relatively large pressure under the pressure of the surrounding soil layer. Large deformation causes the vertical deformation of the segment 4, and the temporary suppo...

Embodiment 2

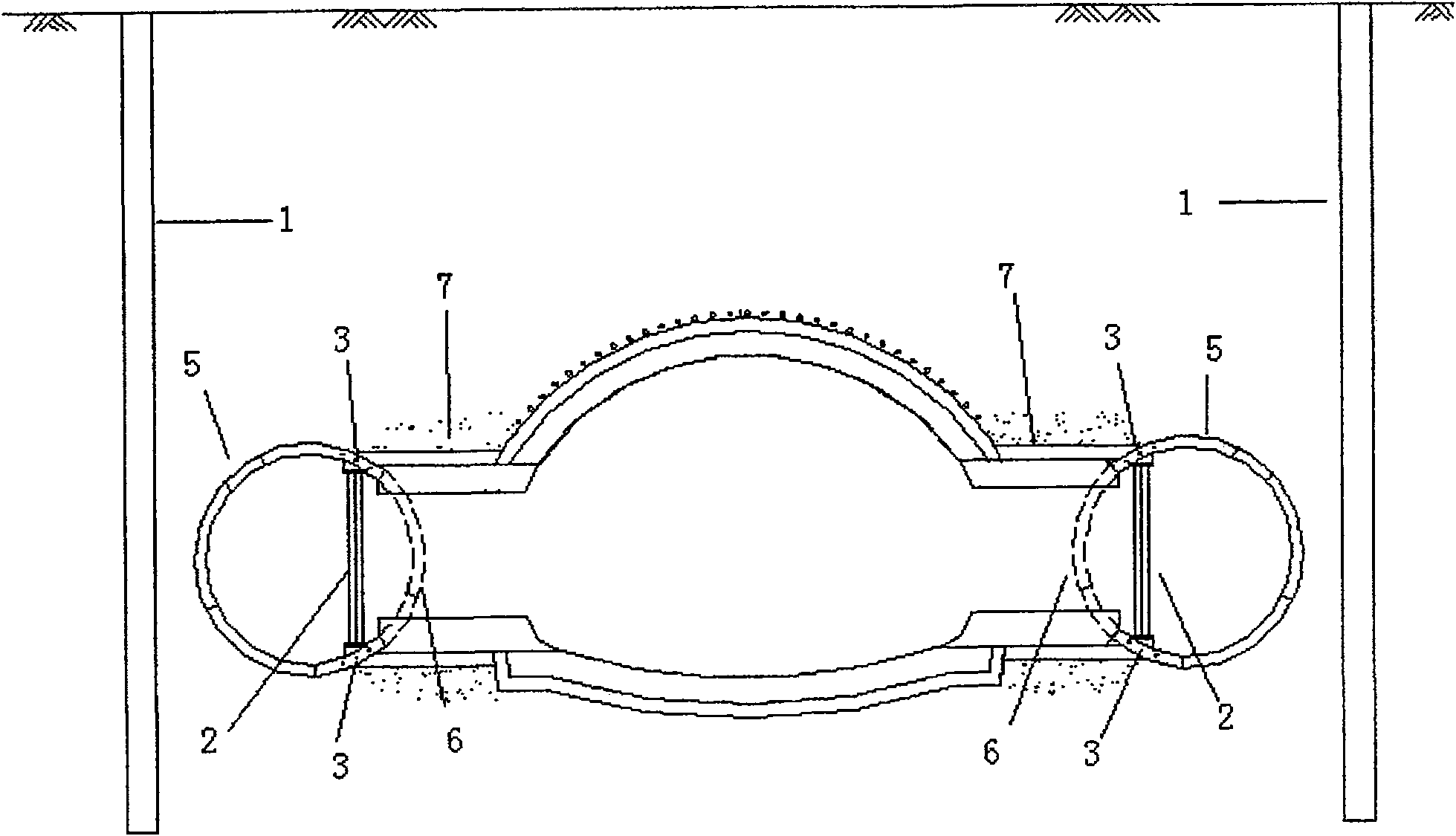

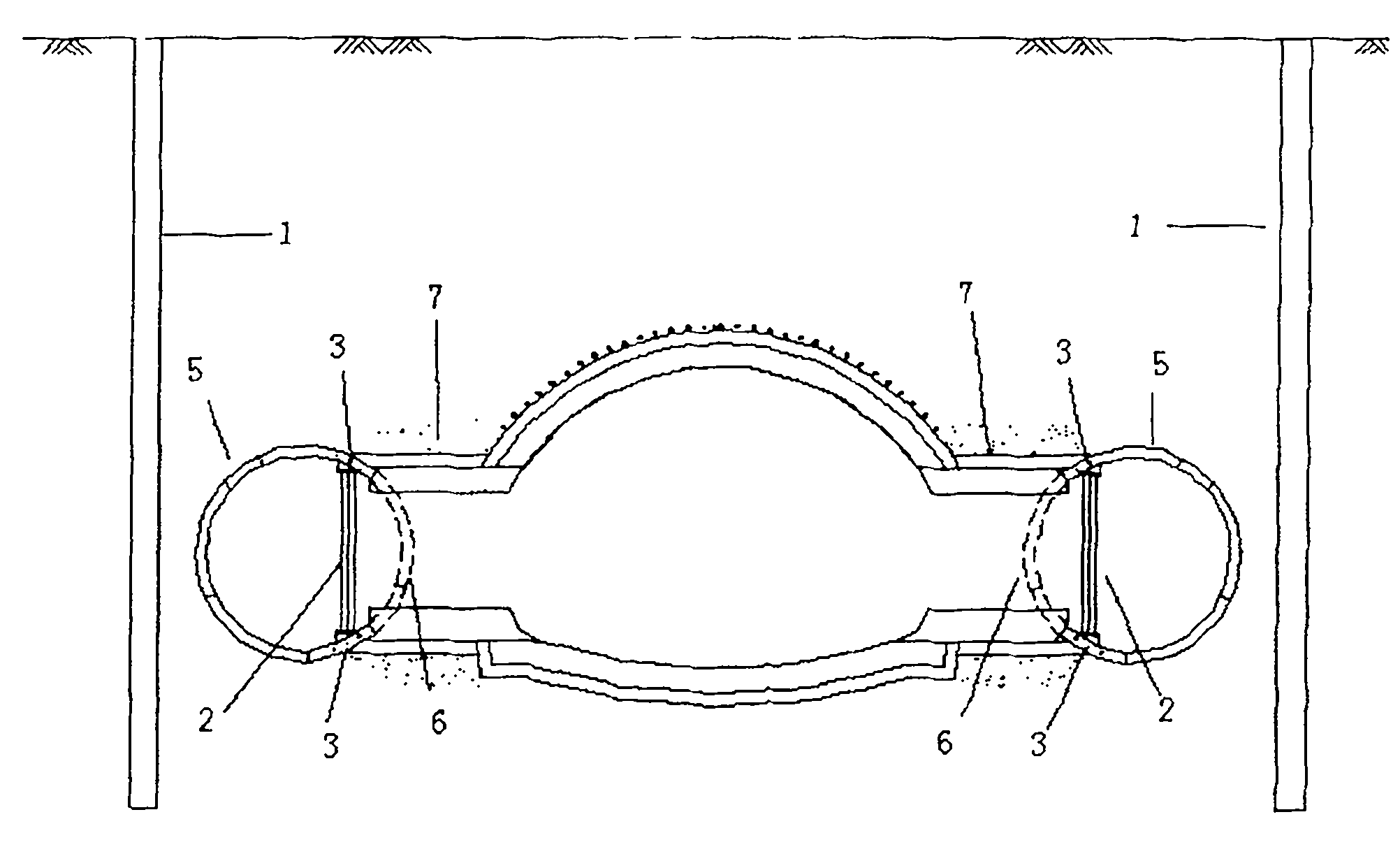

[0028] Embodiment 2: as figure 1 , as shown in 2,

[0029] A row of piles 1 is constructed close to the outside of the shield tunnel to isolate the soil; a vertical temporary support column 2 is erected on one side of the opening of the segment 4 in the shield tunnel, and at the same time, the remaining segment 5 at the opening and the The segments 4 are connected in series in the longitudinal direction through the prestressed steel cables 3 and stretched to form an overall load-bearing structure, thereby reducing the tension and opening tendency of the segment 5 retained at the opening during the breaking of the segment 4, and achieving The purpose of transferring the force system to the adjacent unremoved segment 4.

[0030] A construction method of a pile-column-prestressed support system: the steps are as follows;

[0031] (1) Pile row 1 with appropriate diameter and spacing is adopted near the outside of the shield tunnel to achieve the effect of isolating the soil;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com