Plasma display apparatus

A plasma and display technology, applied in the field of plasma display, can solve the problems of rising manufacturing cost of plasma display panels, and achieve the effects of reducing manufacturing cost, improving discharge diffusion efficiency, and reducing initial discharge voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, preferred embodiments of the present invention will be described in detail based on the drawings.

[0039] However, it goes without saying that the plasma display according to the present invention is not limited to the embodiments described in this specification, and multiple embodiments are possible.

[0040] Below, refer to the attached figure 2 ~ attached Figure 17 , the plasma display related to the present invention will be described in detail.

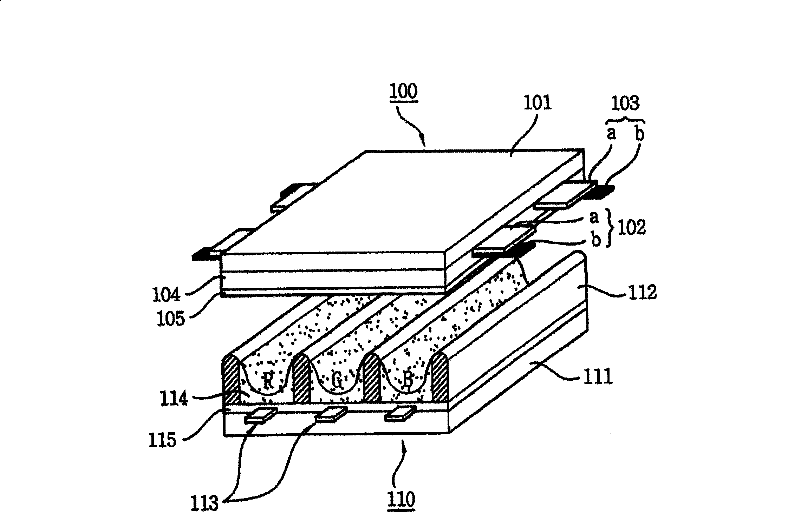

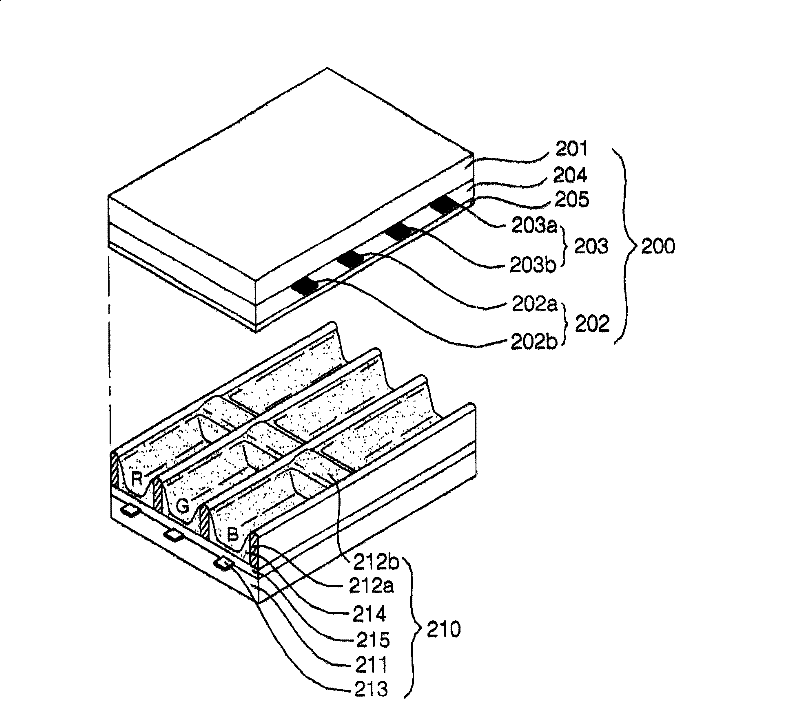

[0041] figure 2 It is a perspective view showing one embodiment of the panel included in the plasma display according to the present invention.

[0042] As shown in the figure, the plasma display panel includes an upper panel 200 and a lower panel 210 bonded at a predetermined interval. Address electrodes 213 formed on lower substrate 211 in a direction intersecting sustain electrode pairs 202 and 203 , and partition walls 212 formed on lower substrate 211 and partition a plurality of discharge cells are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com