Cylinder type waterproof pressure-endurable ballasting

A pressure-resistant cabin and cylindrical technology, which is applied in the direction of electrical equipment shells/cabinets/drawers, electrical components, etc., can solve problems such as poor sealing effects, achieve small frontal resistance coefficient, small frontal resistance, and enhanced resistance corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

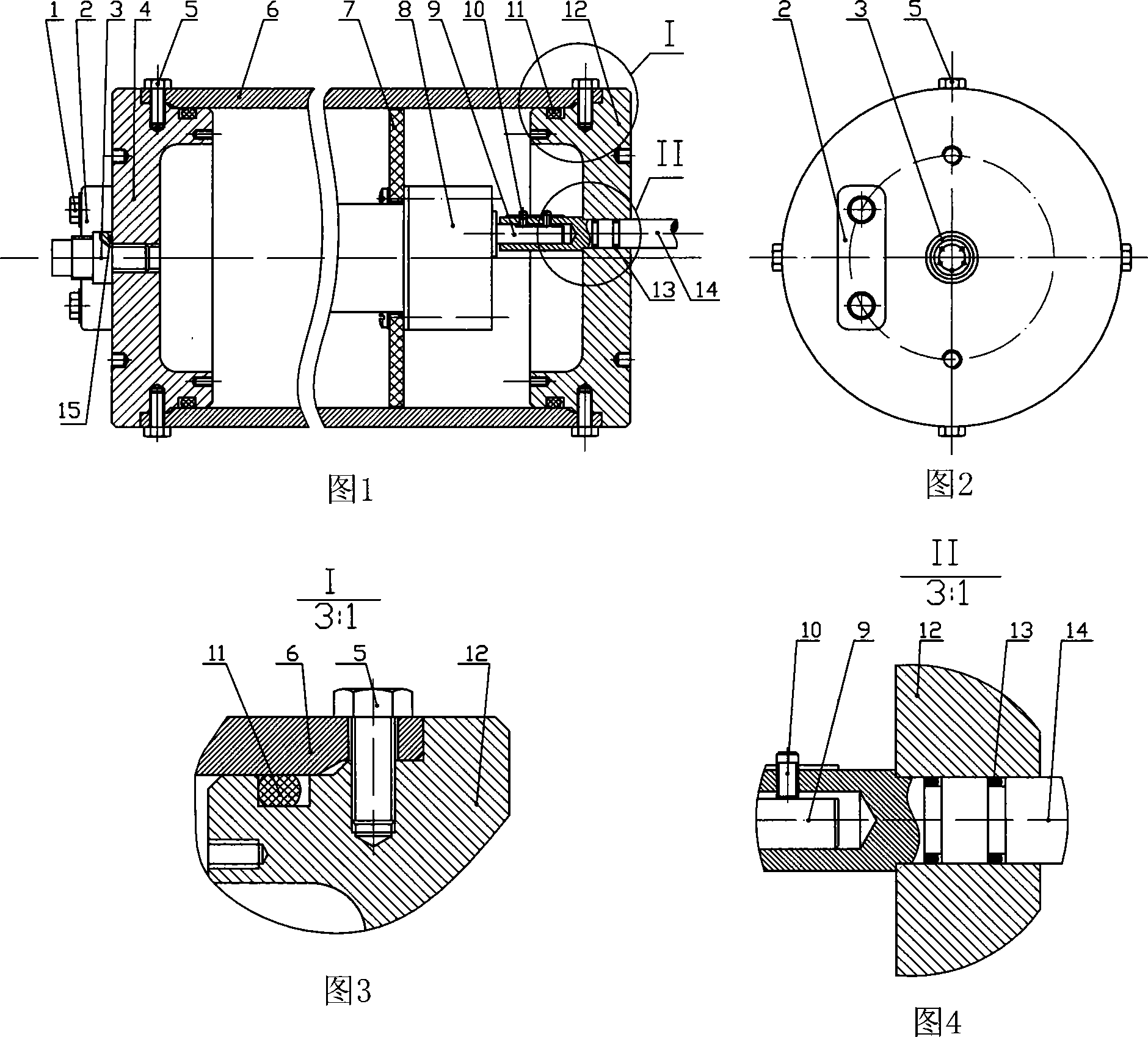

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

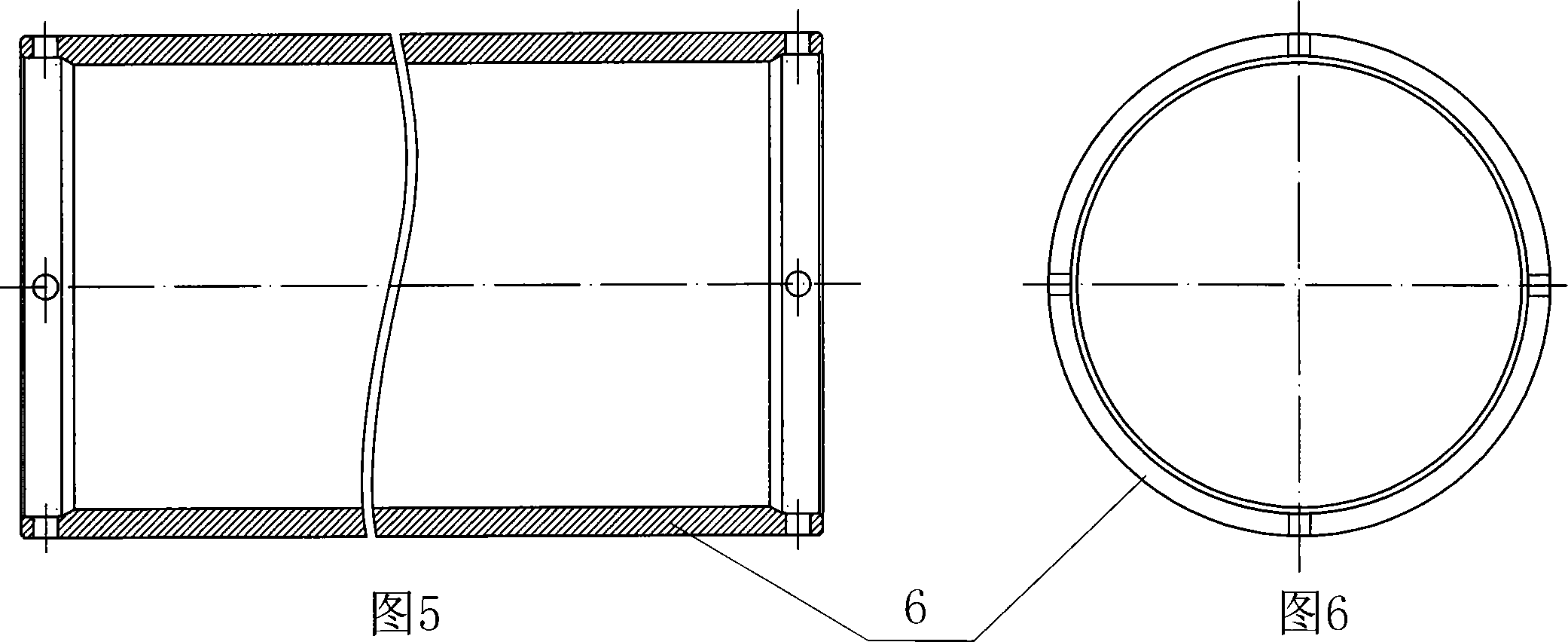

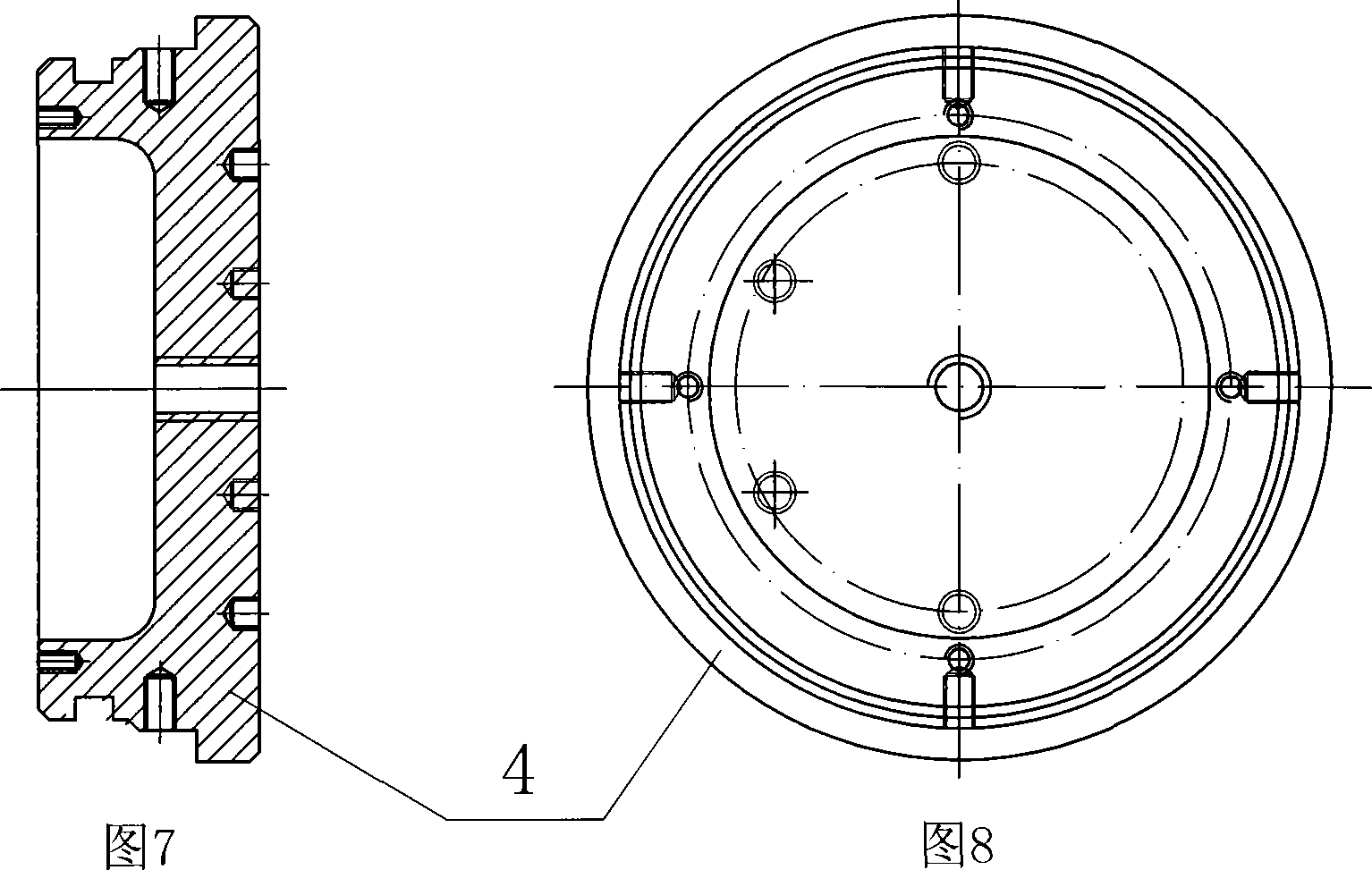

[0041] As shown in Figure 1, the cylindrical watertight pressure-resistant cabin of the present invention includes a sealed shell and additional facilities. The sealed shell is composed of a left end cover, a cylinder and a right end cover, and the additional facilities include sacrificial anodes, cable watertight plugs and Motor extension shaft, etc. It is mainly composed of left end cover 4, cylinder 6, right end cover 12, sacrificial anode 2, cable watertight plug 3, motor extension shaft 14, O-ring 11, O-ring 13, O-ring 15 and fastening bolt 5, etc. . The whole device is based on the left end cover 4, the cylinder 6 and the right end cover 12 connected by fastening bolts 5 and O-ring 11 to form a sealed shell frame; this frame is attached with sacrificial anode 2, cable watertight plug 3 and motor extension shaft 14.

[0042] As shown in Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com