High pressure operation quick release rectification circuit

A rectifier circuit, high-voltage technology, applied in the direction of electromagnets, electrical components, electromagnets with armatures, etc., can solve the problems of affecting the starting and stopping performance of the motor, affecting the service life of the motor, and low voltage at both ends of the brake coil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

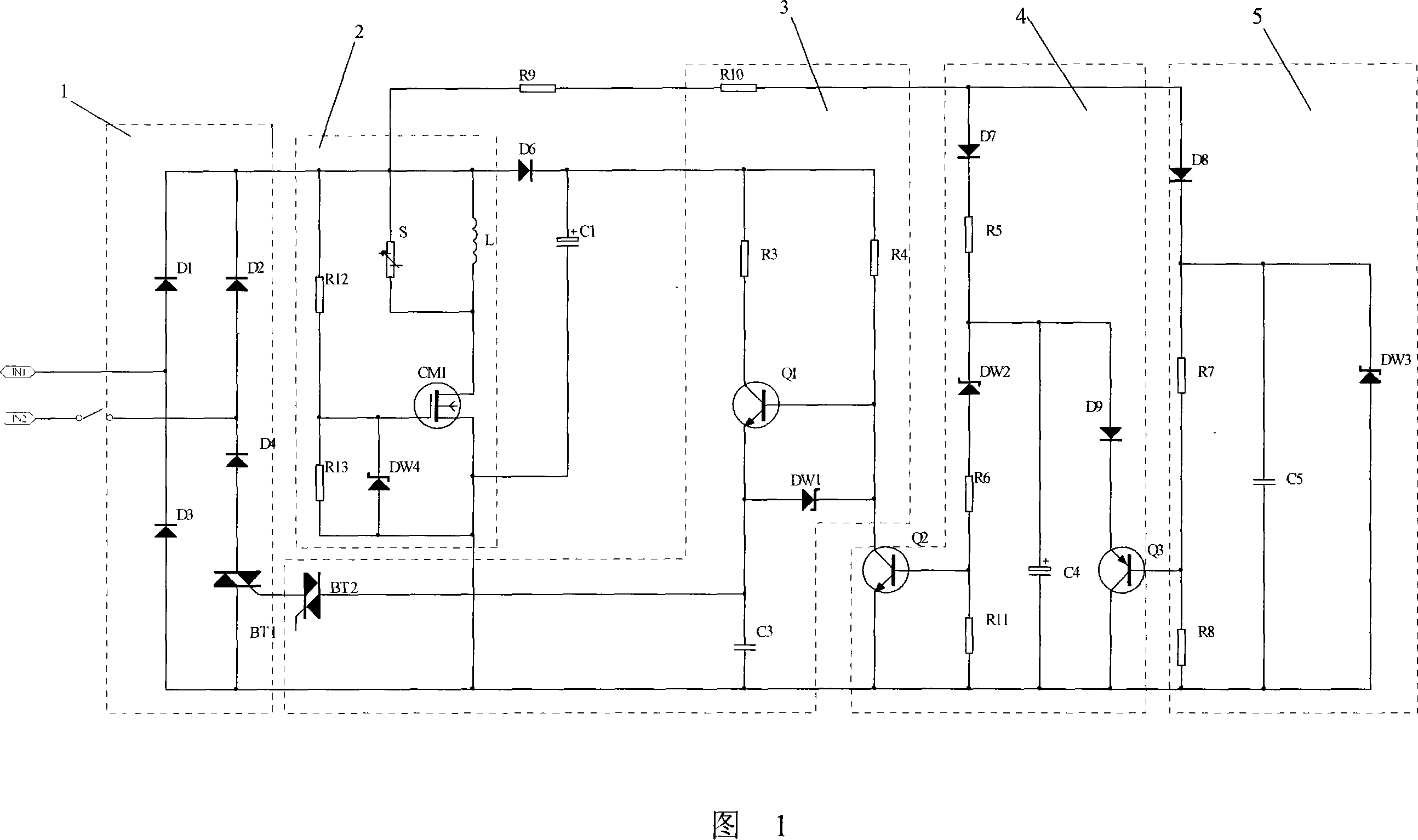

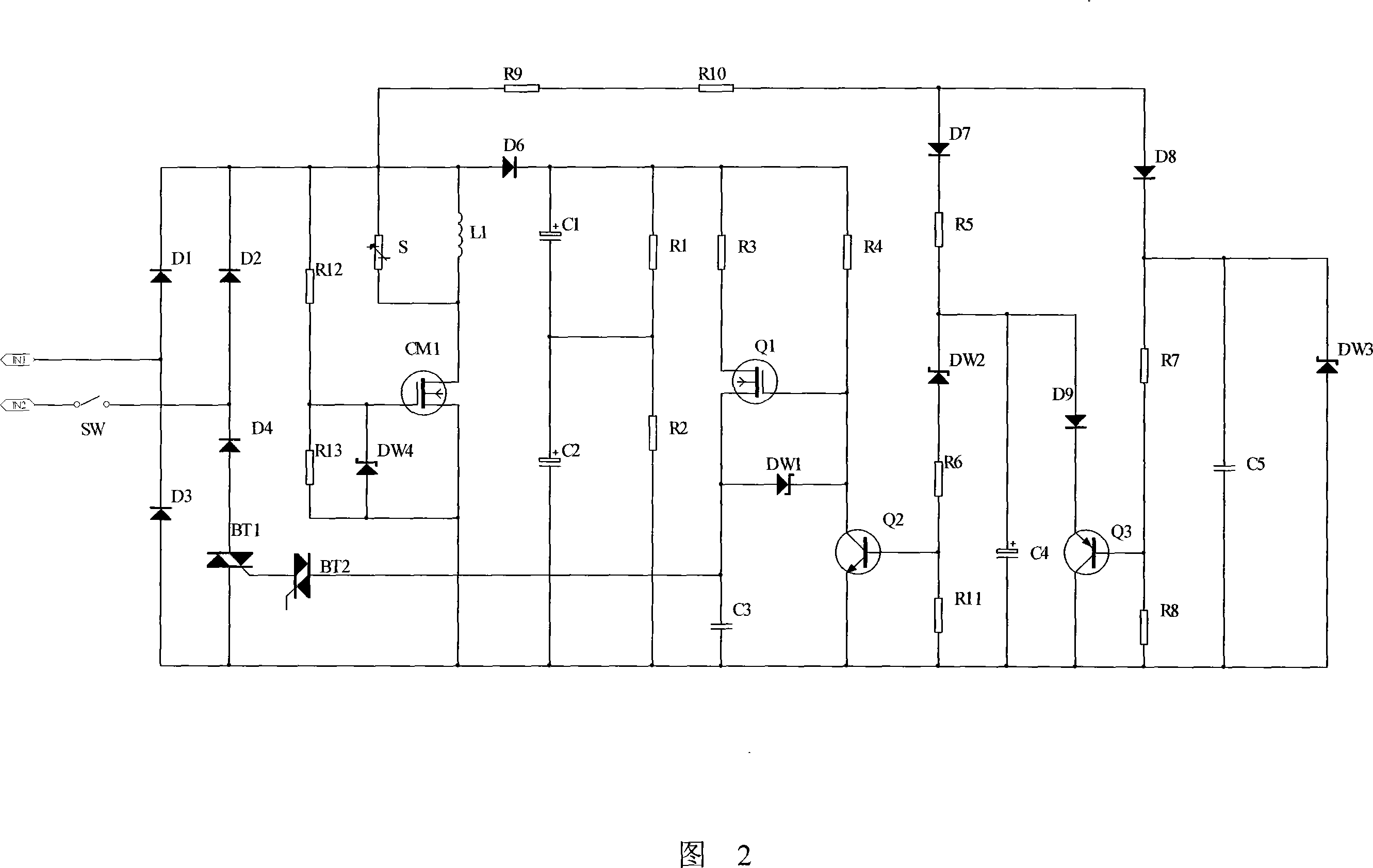

[0017] As shown in Figure 1, the high-voltage pull-in quick-release rectifier circuit shown in the first embodiment of the present invention, the power supply voltage of the motor in this embodiment is 220V, the high-voltage pull-in quick-release rectifier circuit includes a bridge rectifier circuit 1, and the bridge A high-voltage pull-in circuit 2 connected in parallel with a type rectifier circuit, a trigger circuit 3 and a timing circuit 4.

[0018] The rectifier circuit 1 rectifies the alternating current input by the motor into direct current and supplies it to the brake or clutch (the brake is taken as an example below). The input terminal of the rectifier circuit 1 is connected to the motor power switch SW, including diodes D1, D2, D3, D4 and bidirectional The bridge rectifier circuit composed of thyristor BT1, in other embodiments, triac BT1 may also be a unidirectional thyristor. The rectifier circuit 1 also includes a parallel filter circuit, which is composed of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com