Transformer

A technology of transformers and conductors, applied in the field of transformers, can solve problems such as reducing the coupling degree of windings, and achieve the effects of improving efficiency, high coupling degree, and high current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

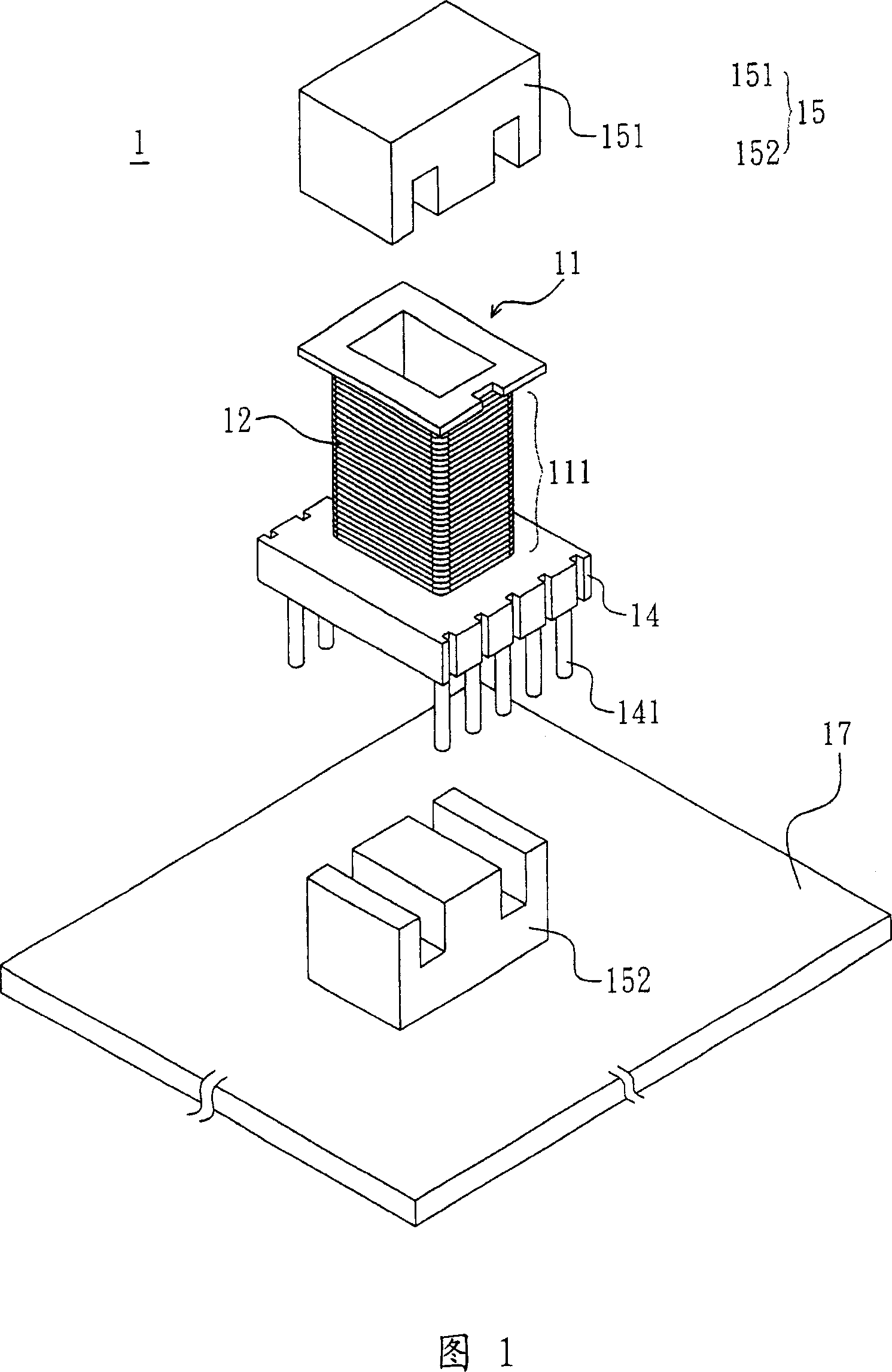

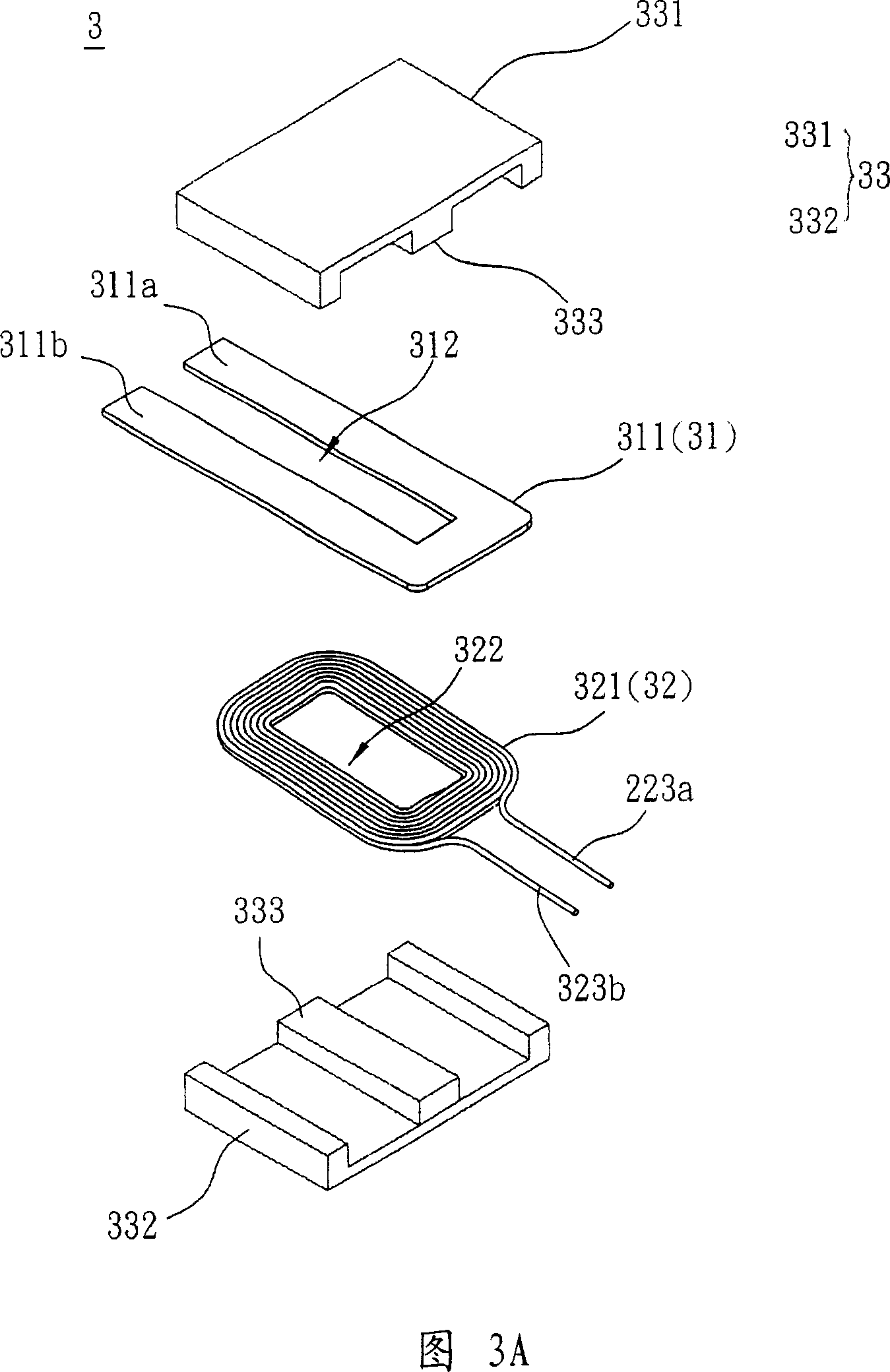

[0049] A transformer according to a preferred embodiment of the present invention will be described below with reference to related drawings, wherein the same elements will be described with the same reference symbols.

[0050] Please refer to FIG. 3A and FIG. 3B at the same time, which is a schematic diagram of a transformer according to a preferred embodiment of the present invention. A transformer 3 according to a preferred embodiment of the present invention includes a first conductor 31 , a second conductor 32 and an iron core 33 . The transformer 3 of this embodiment can be used to modulate the voltage or current of a power supply.

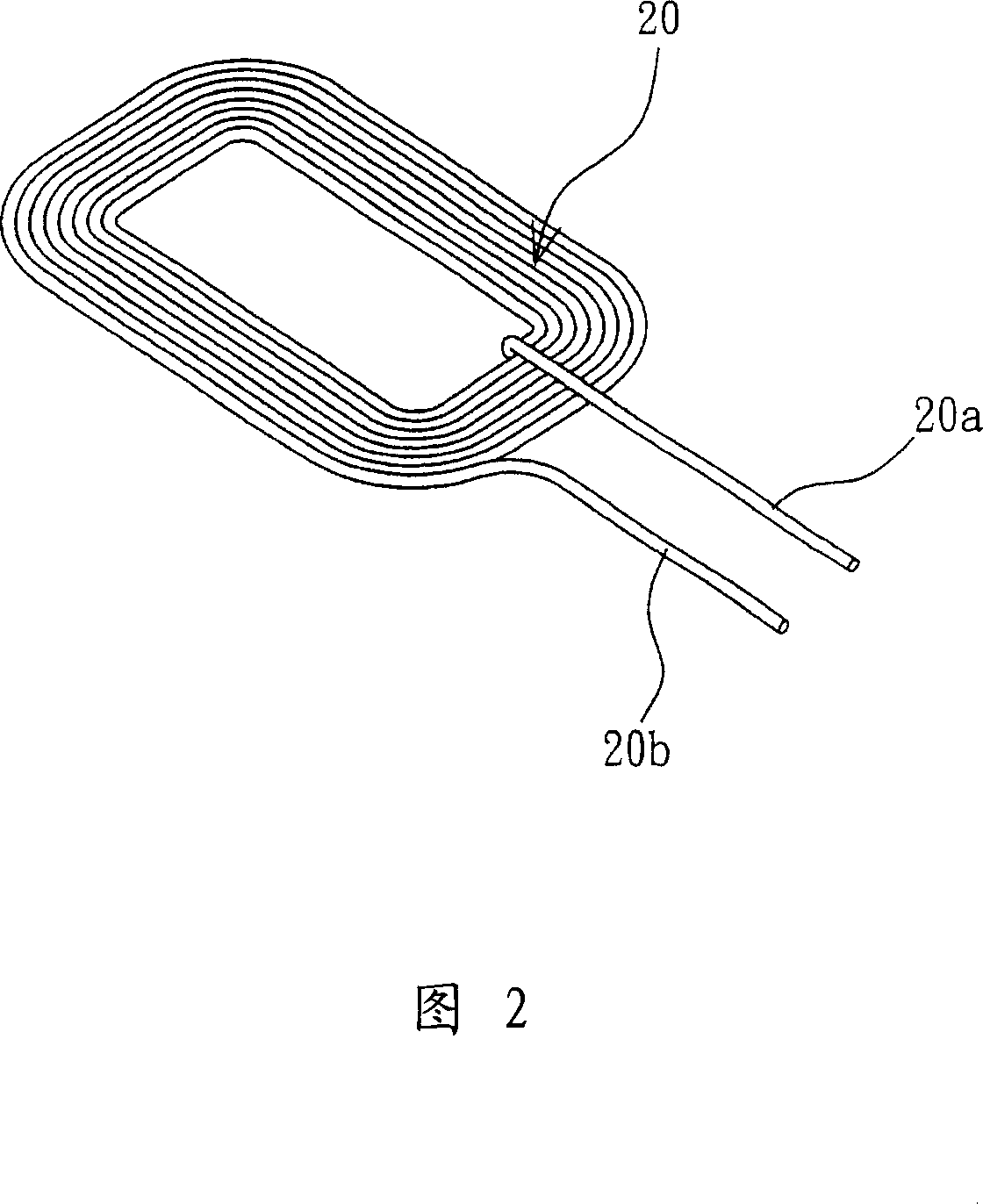

[0051] The first conductor 31 includes at least one conductive sheet 311 , the second conductor 32 includes at least one multilayer spiral coil 321 , and the first conductor 31 and the second conductor 32 are electromagnetically coupled. In this embodiment, the conductive sheet 311 can be a copper sheet.

[0052] The multi-layer spiral coi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com