Plane multi-freedom altrasonic electric machine of single vibrator longtitude bend sandwich changer type

A technology of ultrasonic motors and transducers, which is applied in the direction of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc. The output torque is small, the four driving feet are difficult to guarantee, etc., and the position and excitation combination are easy to determine, the vibration mode is simple, and the output force is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

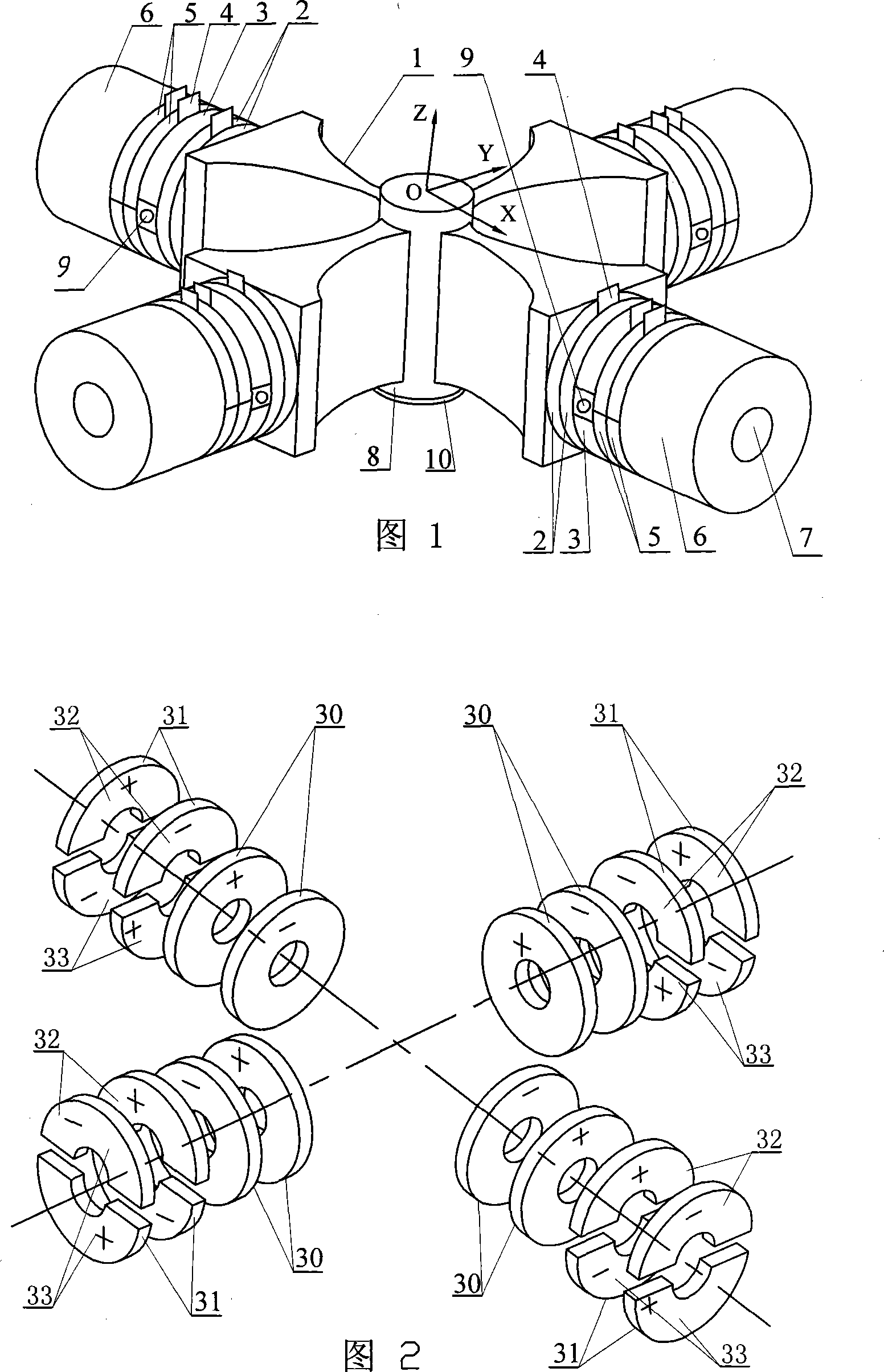

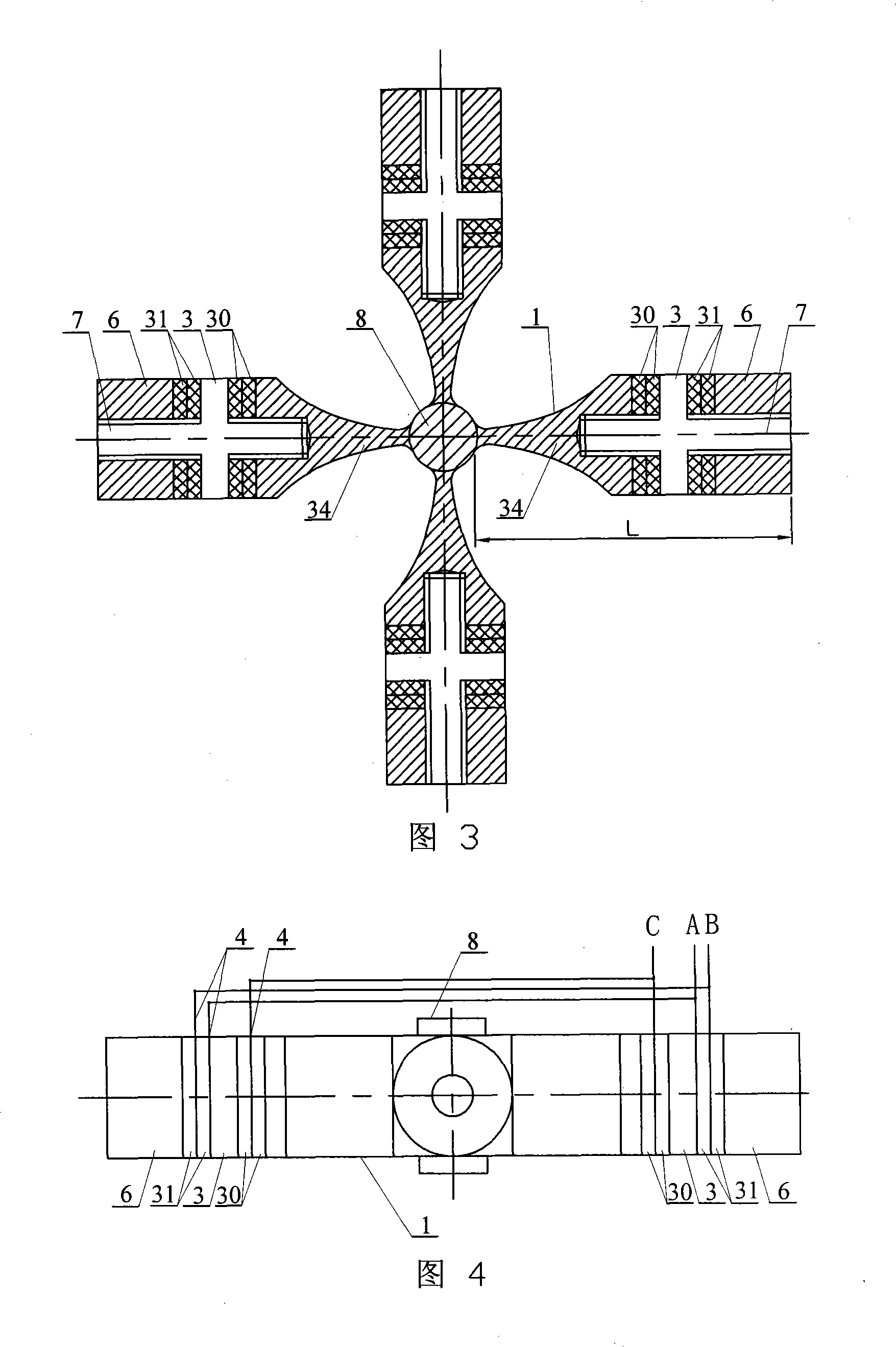

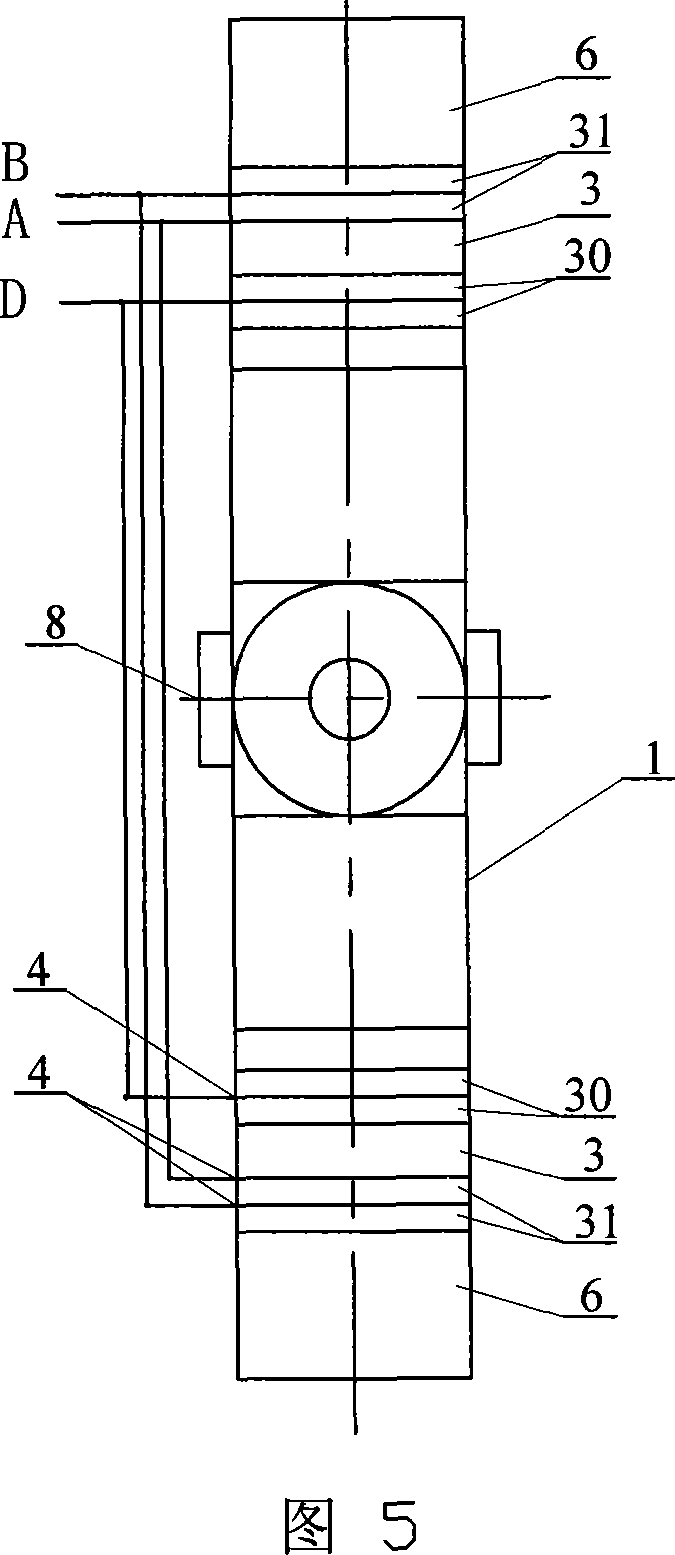

[0007] Specific embodiment 1: This embodiment will be described with reference to Figs. 1 to 5, this embodiment is composed of a single vibrator longitudinal bending sandwich transducer and a driving foot 8; the single vibrator longitudinal bending sandwich transducer is a cross orthogonal luffing The rod 1, the longitudinal vibration piezoelectric ceramic sheet group 2, the flange 3, the electrode copper sheet 4, the bending vibration piezoelectric ceramic sheet group 5, the end cover 6, and the stud 7; the vertical of the cross orthogonal horn 1 A stud 7 is provided on the axis, and the stud 7 is provided with a flange 3, the flange 3 is located at the nodal position of the longitudinal vibration of the single vibrator longitudinal bending sandwich transducer, and the flange 3 is orthogonal to the cross luff The stud 7 between the large end faces of the rod 1 is equipped with a longitudinal vibration piezoelectric ceramic sheet group 2, and the stud 7 between the flange 3 and th...

specific Embodiment approach 2

[0008] Specific embodiment 2: This embodiment will be described with reference to FIG. 3. The cross orthogonal horn 1 of this embodiment is composed of four horns 34 orthogonal in the same plane; the cross section of the horn 34 is Rectangular, the length L of the horn 34 is 1 / 4 or 1 / 2 the longitudinal vibration wavelength. With this arrangement, the horn 34 can reduce the loss of vibration energy on the large end face of the horn 34, play a role in accumulating vibration energy, increase the amplitude and vibration speed of the driving foot 8, and greatly improve the performance of the ultrasonic motor . The other components and connection relationships are the same as in the first embodiment.

specific Embodiment approach 3

[0009] Specific embodiment 3: This embodiment is described with reference to FIG. 1. In this embodiment, two small conical holes 9 are drilled where the longitudinal bending vibration nodes of the outer cylindrical surface of the flange 3 overlap. This setting is used as the clamping point of the ultrasonic motor pre-tightening force mechanism to apply pre-tightening force to generate driving friction, or to drive the load there. Choosing to drill two small conical holes 9 at this position has the least influence on the vibration shape of the single vibrator longitudinal-bending sandwich transducer and can reduce energy loss. The other components and connection relationships are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com