Acid resistant particles of an alkaline earth metal carbonate

A technology of alkaline earth metals and carbonates, applied in nanotechnology for materials and surface science, thin material processing, fibrous fillers, etc., can solve the problem of unsatisfactory performance of hydrophobic coated carbonate particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

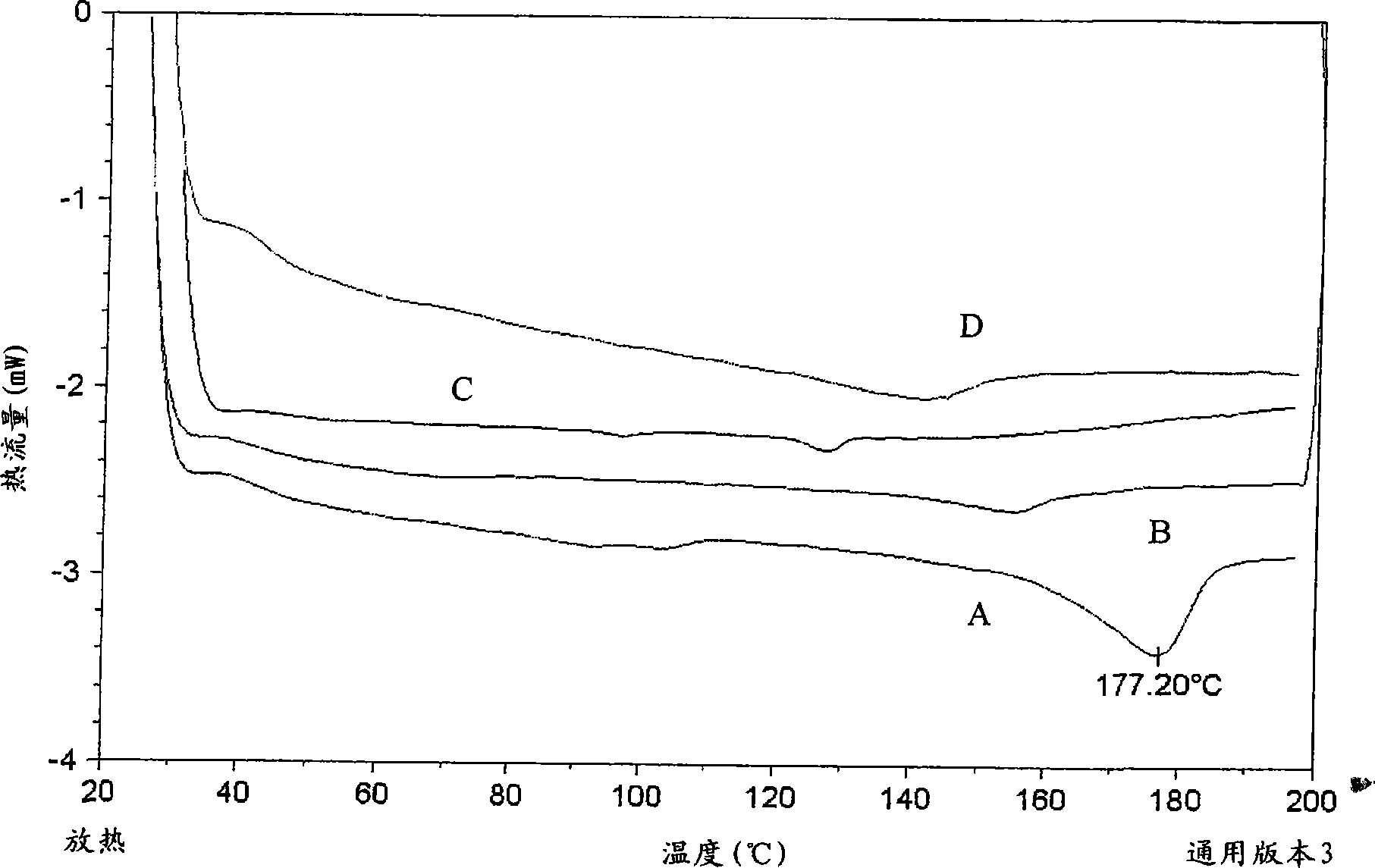

Image

Examples

Embodiment 1

[0095] Example 1 (particles according to the invention)

[0096] In the first step, 500 liters of 200 g / L uncoated precipitated carbonic acid were treated with 2.8 kg stearin / 100 kg of PCC, i.e., 28 L of an aqueous emulsion (first coating agent) containing 10 wt % stearin Suspensions of calcium, said uncoated precipitated calcium carbonate characterized by a base particle size (d p ) is 70nm and the specific surface area (BET) is 20m 2 / g. The particles were exposed to the emulsion for 45 minutes at 75°C.

[0097] The particles were then separated from the emulsion by a filter, dried in an oven at 105°C until the water content was below 3 g / kg, and milled.

[0098] In a second step, 3.35 kg of stearin (second coating agent) was injected into the Cell Mill dryer containing 100 kg of previously coated PCC. Adjust the outlet temperature at 180-200°C. After 2 minutes, all solids were recovered.

Embodiment 2~5

[0108] Particles were prepared according to the procedure of Example 1, except that the precipitated calcium carbonate particles were coated with 4.5, 4.8, 5.5 and 6.9 kg of stearin per 100 kg of precipitated calcium carbonate, respectively.

Embodiment 6

[0110] Particles were prepared according to the procedure of Example 1, except that abietic acid was used instead of stearic acid to coat the precipitated calcium carbonate particles in an amount of 5.5 kg abietic acid per 100 kg precipitated calcium carbonate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dispersity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com