Method for manufacturing a periodically-poled structure

A manufacturing method and polarization technology, applied in the fields of nonlinear optics, instruments, optics, etc., can solve the problems such as the failure to improve the manufacturing yield of wavelength conversion elements, crystal damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

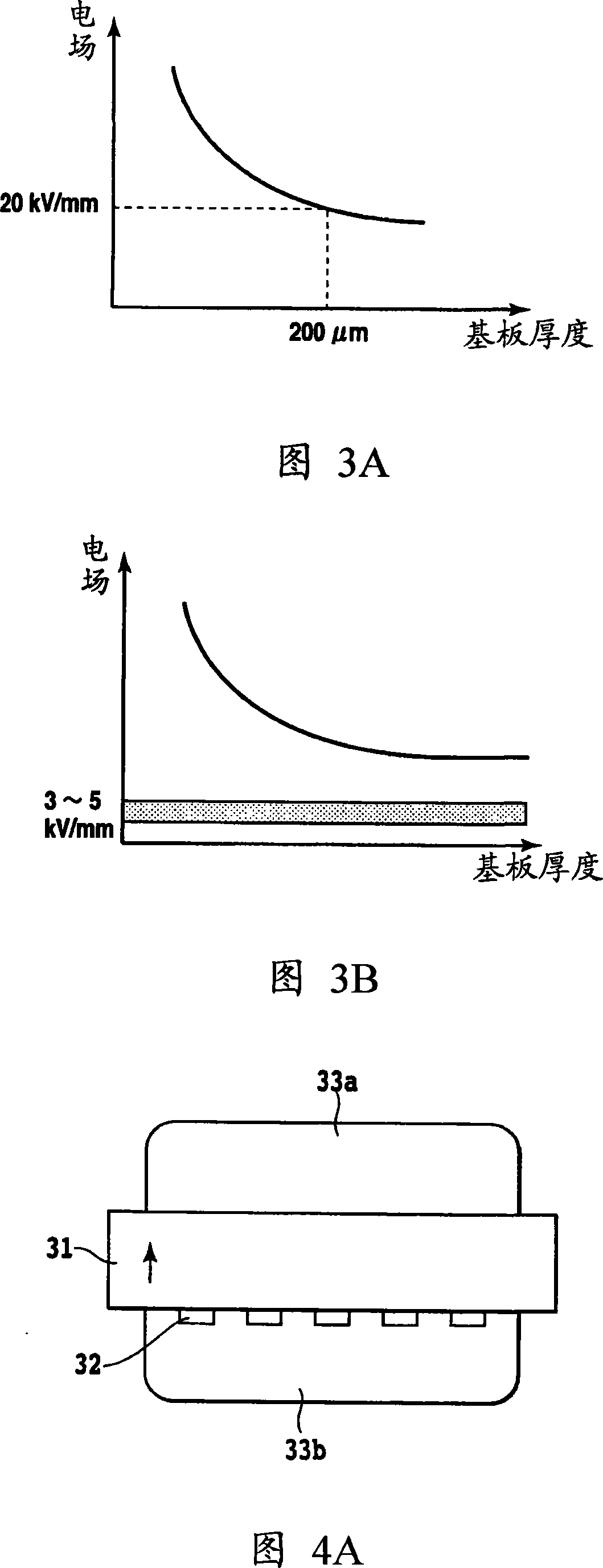

[0041] FIG. 5 shows a method of manufacturing the periodic polarization inversion structure according to the first embodiment. In Example 1, a 3-inch Zn-doped LN substrate with a substrate thickness of 300 μm was used as the secondary nonlinear optical crystal. The LN substrate 41 is mono-domained, and a resist pattern 42 corresponding to a periodic polarization inversion structure is formed on the -Z surface.

[0042] Fabrication of the resist pattern 42 is performed by an ordinary photolithography process. After the organic cleaning, the surface of the LN substrate 41 is subjected to lipophilic treatment, and then S1818 resist (Resist) manufactured by Shipley Co., Ltd. is dropped on the substrate to carry out spin coating. The resist film after spin coating is Drying and curing by baking in a constant temperature oven. The substrate will not be damaged by heating during coating or subsequent cooling. This is because the substrate thickness of the LN substrate 41 is 300 mi...

Embodiment 2

[0047] In Example 2, the same method as in Example 1 was used to fabricate a periodic polarization inversion structure on a 3-inch Zn-doped LN substrate with a substrate thickness of 5 mm. Manufacture of a resist pattern corresponding to a periodic polarization structure was carried out in the same manner as in Example 1, and a resist pattern with a period of 4.5 microns was produced.

[0048] FIG. 6 shows a method of manufacturing the periodic polarization inversion structure according to the second embodiment. In Example 2, the polarization inversion structure was produced in a state where the LN substrate 41 was heated by housing the container 43 used in Example 1 in a mantle heater. The container 43 is made of polycarbonate having excellent heat resistance. Here, the thermocouple 52 was heated to 90° C. in a state where the container 43 was housed. The LN substrate 41 is not damaged during heating. This is because the LN substrate 41 has a thickness of 5 mm and is highl...

Embodiment 3

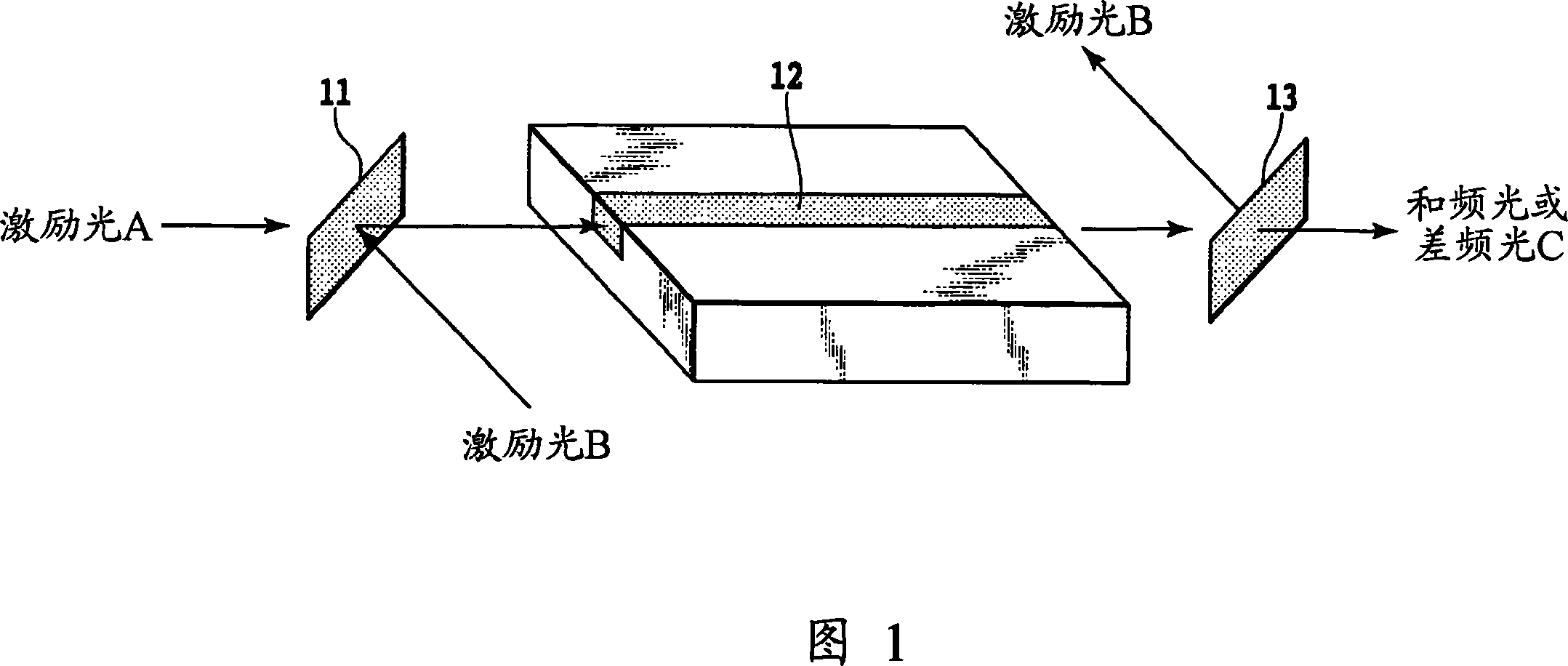

[0053] In the same manner as in Example 1, a periodic polarization inversion structure was fabricated using a 3-inch Zn-doped LN substrate with a substrate thickness of 300 μm. Manufacture of a resist pattern corresponding to a periodic polarization structure was carried out in the same manner as in Example 1, and a resist pattern with a period of 28.5 microns was produced. A strip-shaped element is cut out from the produced LN substrate in a direction perpendicular to the periodic polarization inversion structure, and then both end surfaces of the cut element are ground. When excitation light with a wavelength of 1560 nm and excitation light with a wavelength of 1060 nm are incident on the element in a direction perpendicular to the periodic polarization inversion structure, difference frequency light as mid-infrared light with a wavelength of 3.3 μm can be generated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com