Refrigerated container possessing anti collision board

A technology of refrigerated containers and anti-collision plates, which is applied in the direction of packaging, transportation and packaging, and the upper structure of trucks, etc., can solve the problems of easy damage of inner panels, achieve simple processing technology, reduce preparation time, and offset stress concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

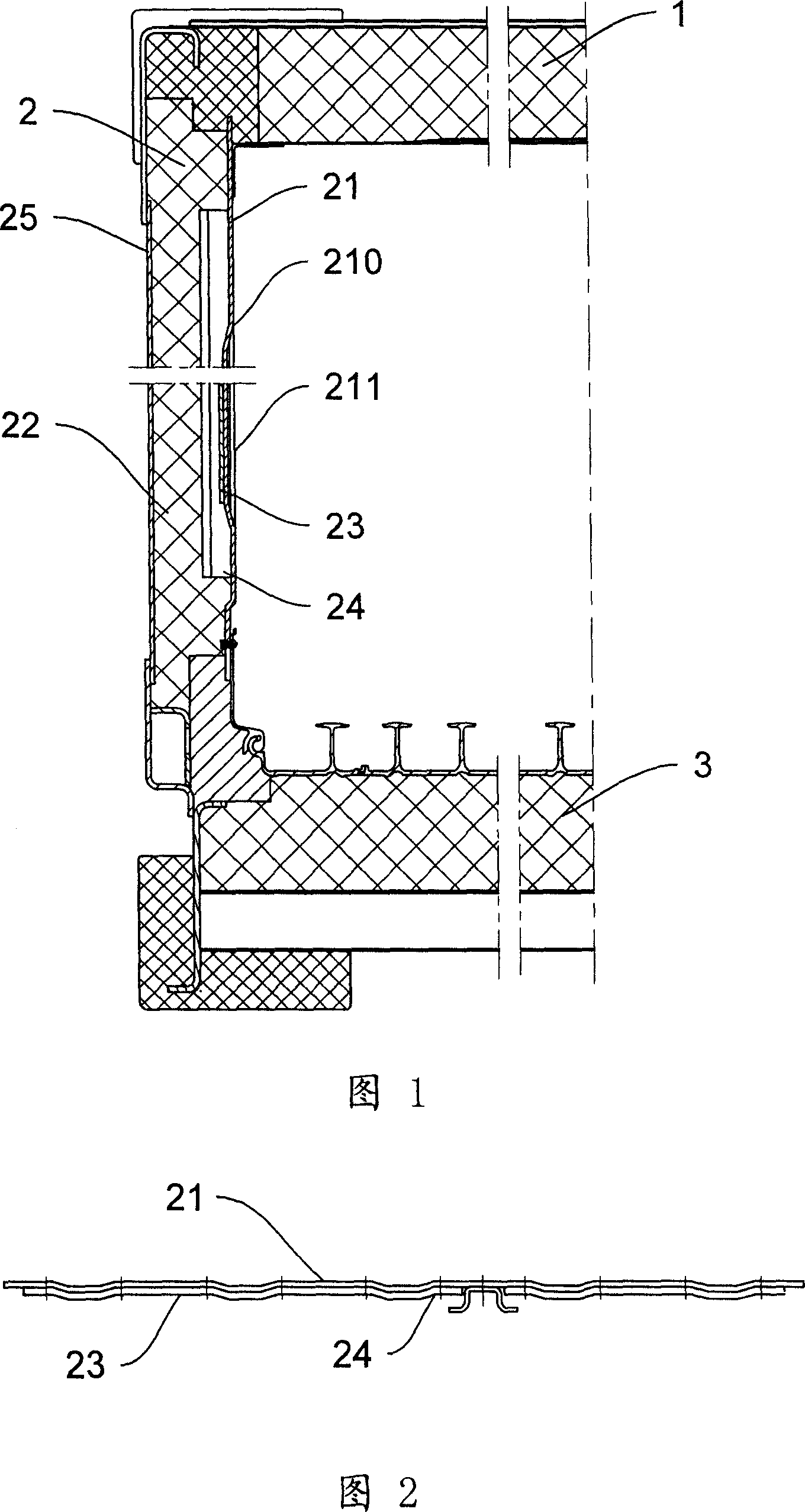

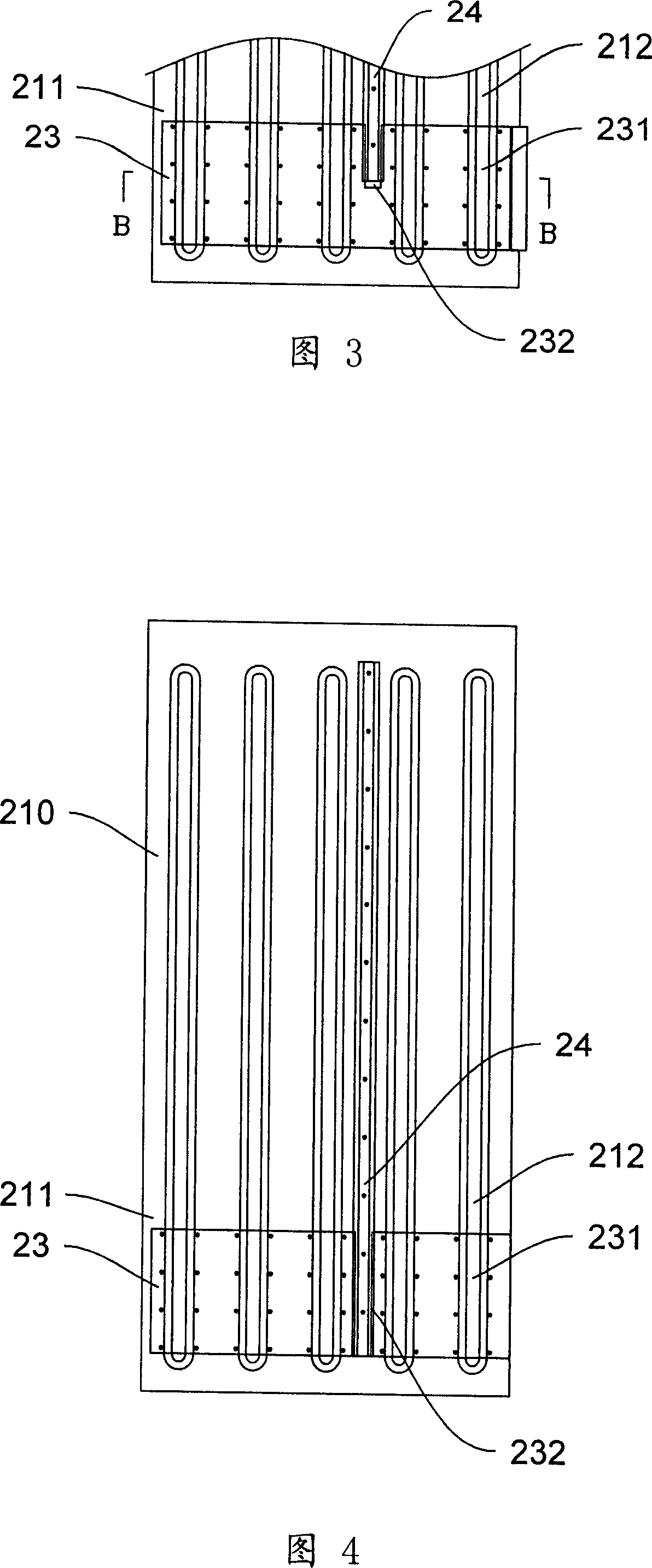

[0017] As shown in Figures 1, 2 and 3, in the refrigerated container with anti-collision panels according to the present invention, it includes a box surrounded by a roof 1, a side wall 2 and a floor 3, and the side wall 2 usually includes an inner side panel 21 , the outer panel 25 , and the foam layer 22 arranged between the inner panel 21 and the outer panel 25 . The outer surface of the inner side plate 21 is provided with a reinforcing rib 24 in the vertical direction, that is, a reinforcing rib 24 is provided between the outer side plate 25 and the inner side plate 21 and the reinforcing rib 24 is fixed on the inner side plate 21. The upper part 210 of the inner side board extends to the lower part of the inner side board 21 at a height of 400 mm from the lower end. An anti-collision plate 23 is provided on the outer surface of the inner side plate 21, and the anti-collision plate 23 covers the lower part 211 of the inner side plate by spot welding. The lower part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com