Conveyer belt made from rubber with metal core fabric

A metal core and conveyor belt technology, applied in the field of conveyor belts, to achieve reasonable structural design, prevent structural elongation of fabrics, and overcome delamination and peeling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

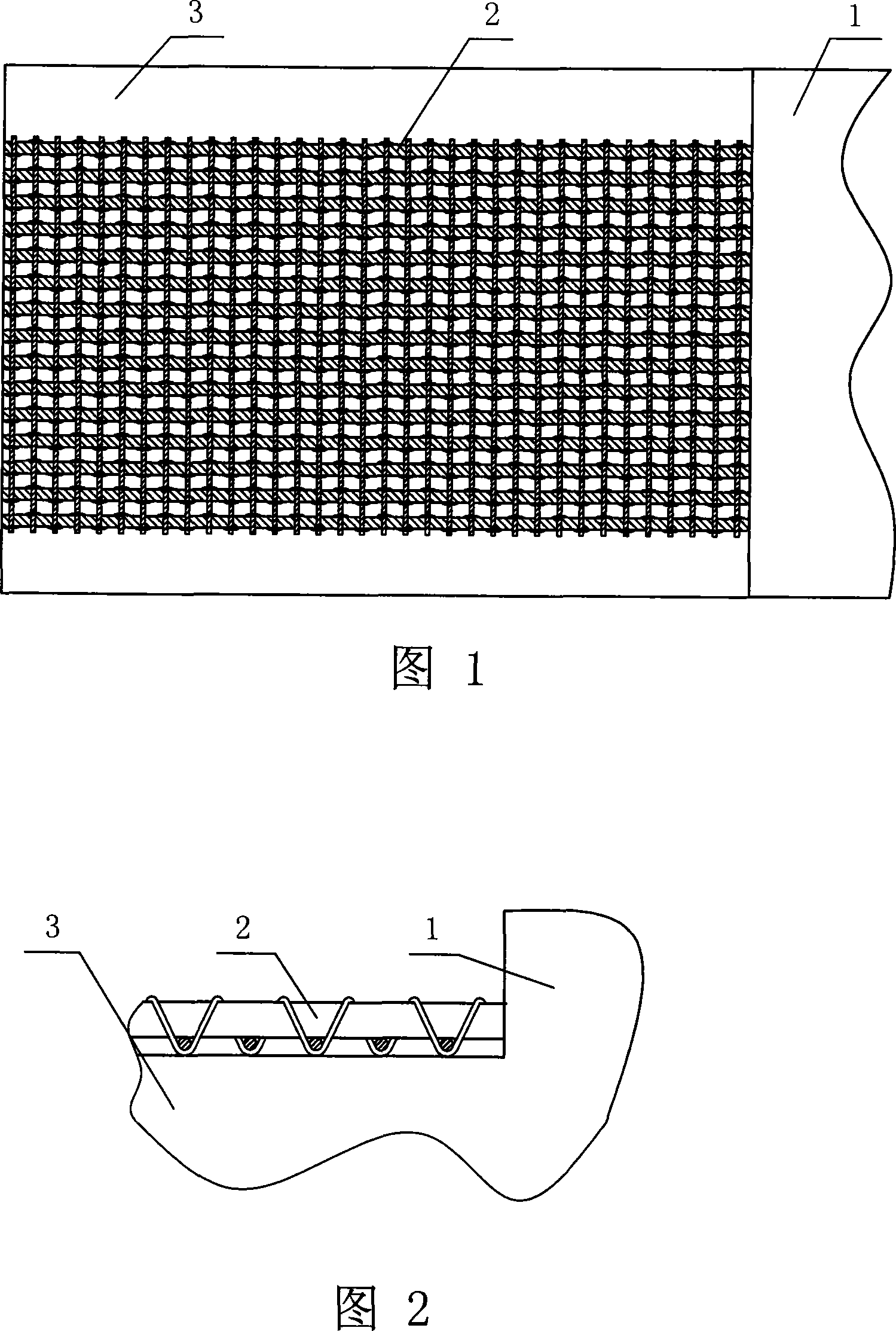

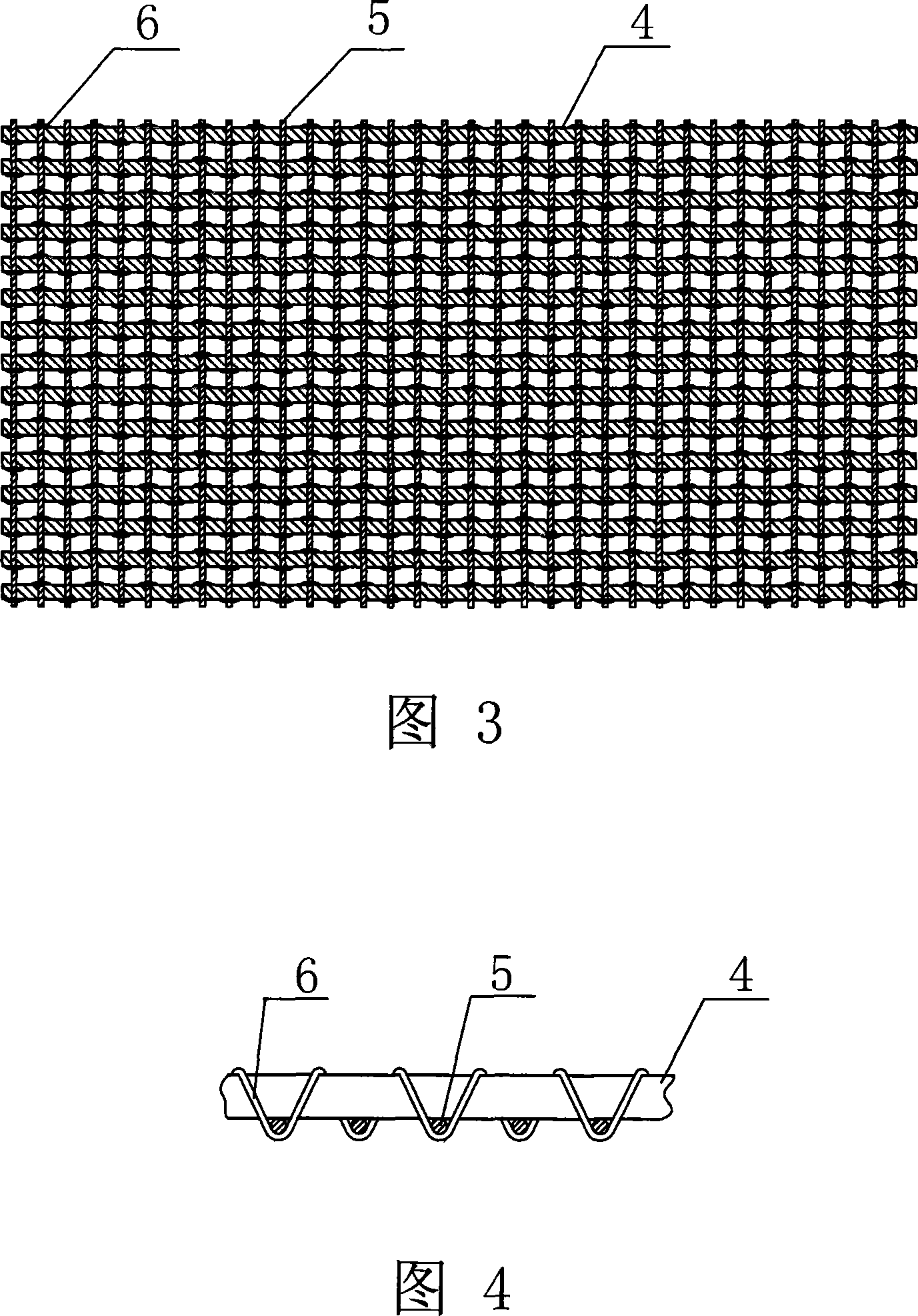

[0014] The specific structure of the present invention will be described in detail according to FIGS. 1 to 4 . The conveyor belt includes an upper cover glue 1, a lower cover glue 3 and a skeleton bonded therebetween. Wherein the skeleton adopts the straight warp and straight weft metal core cloth 2 woven by metal warp threads 4, metal weft threads 5 and metal twisted warp threads 6. The metal warp 4 adopts steel wire rope, the metal weft 5 adopts steel wire or steel wire rope, and the metal twisted warp 6 adopts metal materials such as iron wire instead of traditional natural fiber or chemical fiber. These metal materials have sufficient sources, convenient procurement, and relatively low cost, such as 9,000 yuan / ton for steel wire rope and 23,000 yuan / ton for nylon.

[0015] The uniqueness of the present invention is just that: 1, metal warp thread 4 adopts steel wire rope, and the breaking strength of steel wire rope is far greater than nylon, polyester fiber of the same d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com