Method for preparing inorganic Nano / micro tube

An inorganic nano- and micro-tube technology, which is applied in separation methods, chemical instruments and methods, welding equipment, etc., can solve the problems of inability to prepare nano-tubes with uniform morphology, and limit the application of materials, so as to avoid design problems and preparation processes. Simple and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The method for preparing inorganic nanometer / microtube of the present invention, carries out as follows successively:

[0031] First weigh an appropriate amount of solvent, then weigh the weak acid salt of the metal ion to prepare a concentration and polymer to prepare a polymer solution with a concentration range of 1% to 80%, and the molar ratio of the inorganic salt ion to the polymer ranges from 0.05 to 3 ;The aging temperature range of electrospinning precursor solution is -10℃~95℃;

[0032] Put the mixed solution into a constant temperature water bath for low-temperature aging, and the aging time is 0-120 days to obtain an electrospinning precursor solution;

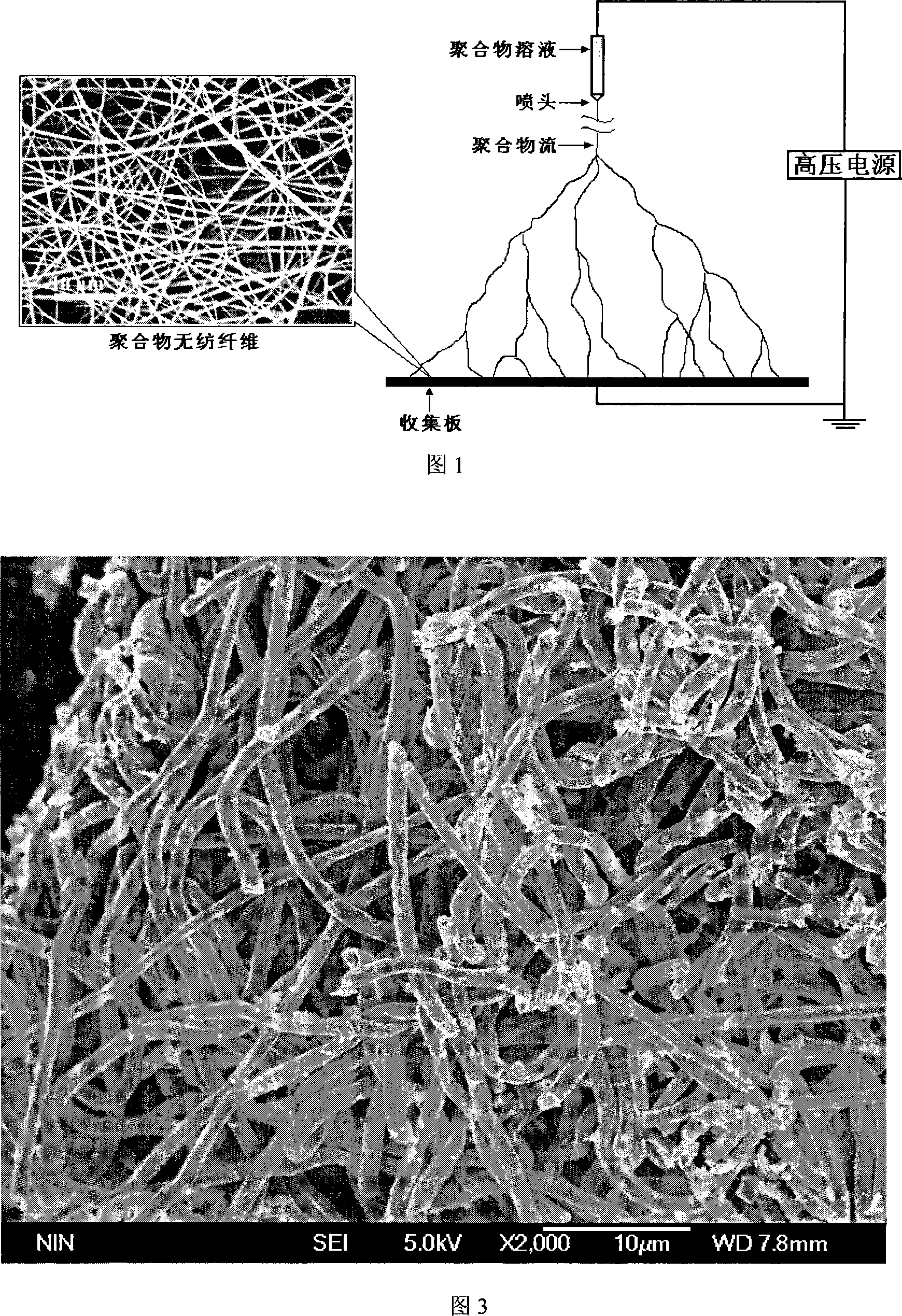

[0033] The precursor solution was electrospun on a conventional single-tube electrospinning device, and the electrospun product was collected with a conductive metal plate covered with aluminum foil; the ambient temperature range during the electrospinning process was 0°C to 150°C, and the environment during...

Embodiment 1

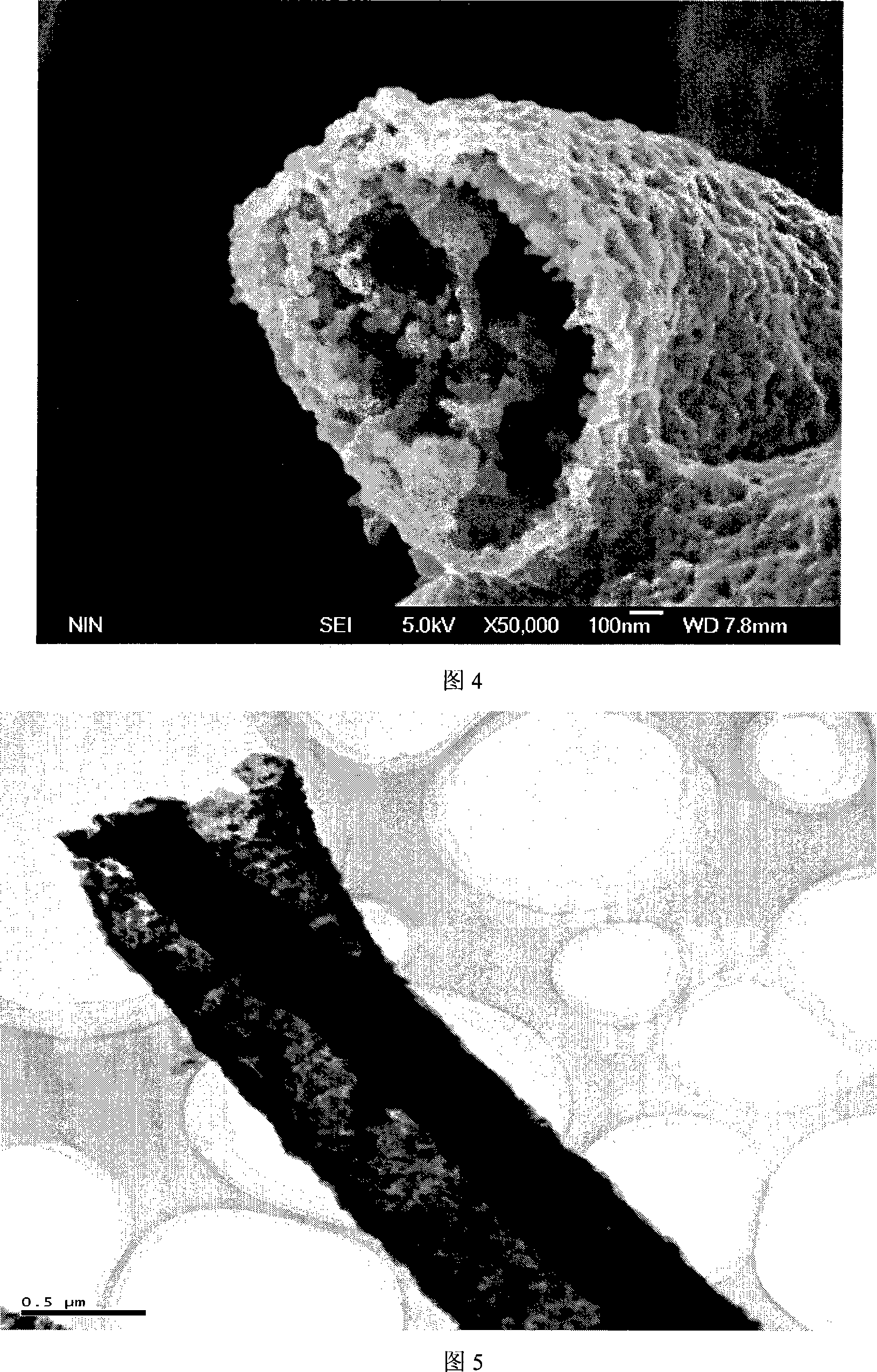

[0053] First add 14g methanol and 3g ethanol solution into the reaction flask, after stirring evenly, add 1.0g Zn(CH 3 CH 2 O) 2 4H 2 O and 1.0gMn(CH 3 CH 2 O) 2 4H 2 O crystal, after stirring to completely dissolve the inorganic salt, add 2.0g of polyvinylpyrrolidone (referred to as PVP, K90, Mw=1,000,000~1,500,000) powder, after the PVP powder is completely dissolved, weigh the solution and put it in a constant temperature water bath The pot is aged at 24°C. During the aging process, the volatilized solvent is timely compensated. After the solution was aged for 20 days, the required electrospinning precursor solution was prepared. Take an appropriate amount of this electrospinning precursor solution and add it to a glass nozzle equipped with a No. 9 injection needle, turn on the power supply, and perform electrospinning at a DC voltage of 12.0 kV. The distance between the needle and the collecting plate is 9.0 cm. The temperature was 23°C and the relative humidity wa...

Embodiment 2

[0055] First add 14g methanol and 1g ethanol solution into the reaction flask, stir evenly, then add 2.0g Mn(CH 3 CH 2 O) 2 4H 2 O was added to the volumetric flask, and after the inorganic salt was completely dissolved, 2.0g of PVP (K90) powder was added and stirred. After the PVP powder was completely dissolved, the solution was weighed and placed in a constant temperature water bath for aging at 26°C. During the aging process, timely compensate for the volatilized solvent. After the solution was aged for 14 days, the electrospinning precursor solution was obtained. Take an appropriate amount of precursor solution and add it to a glass nozzle equipped with a No. 8 needle for injection, turn on the power supply, and perform electrospinning at a DC voltage of 9.0kV. The distance between the needle and the collecting plate is 10.0cm, and the electrospinning ambient temperature The temperature is 24°C and the relative humidity is 53%. A plain copper plate covered with alumi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com