Method for injecting retarder to coal body

A technology of chemical inhibitor and coal body, which is used in earth-moving drilling, safety devices, mining equipment, etc., can solve the problem that the inhibitor is not successful enough to prevent fire, the inhibitor cannot evenly wet and wrap the coal body, and the inhibitor cannot completely Play the role of inhibition and other problems to achieve the effect of reducing concentration, prolonging the natural ignition period, and enhancing the effect of dust reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

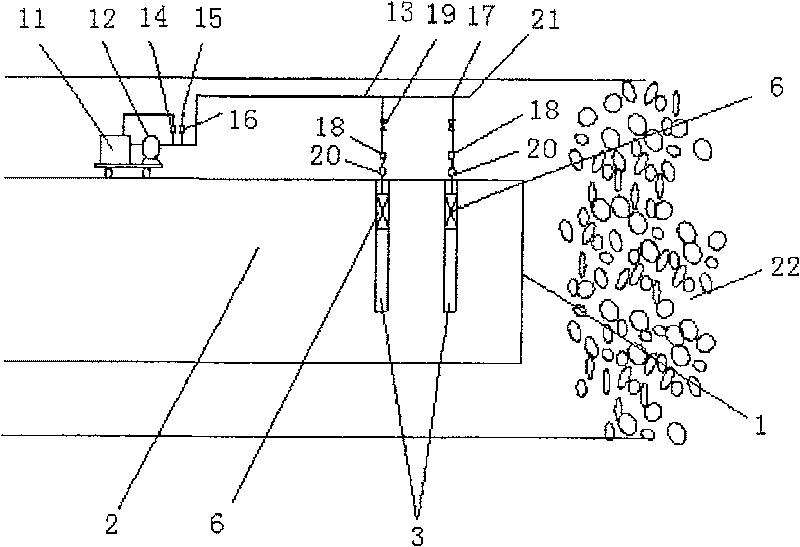

[0044] The method of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0045] like figure 1 Shown, the inventive method comprises the following steps:

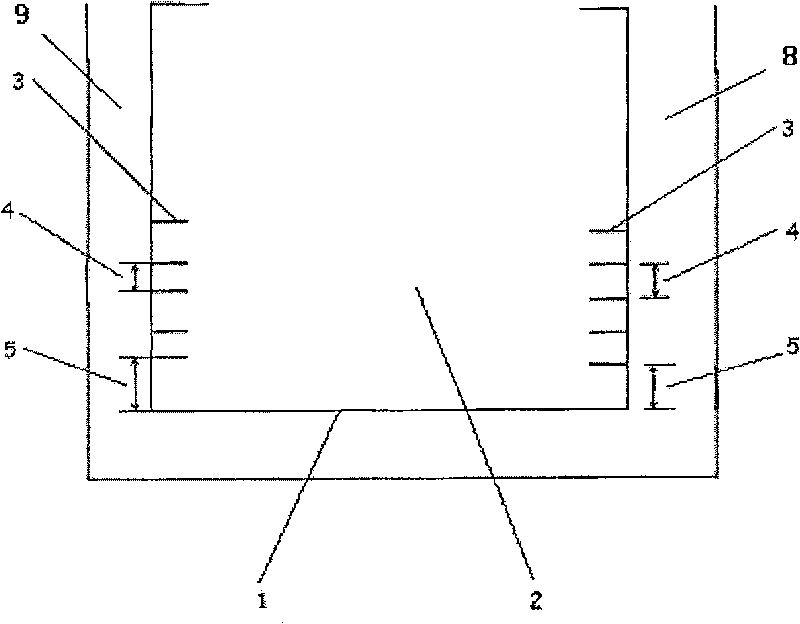

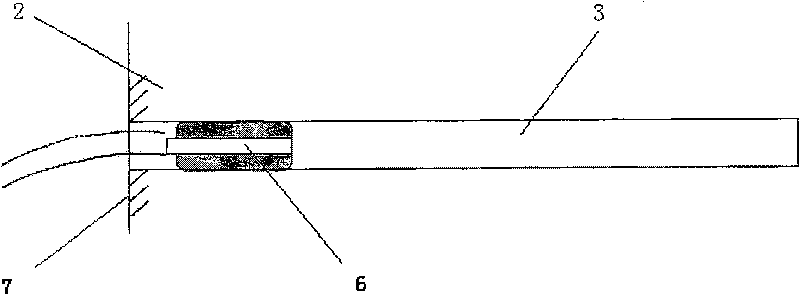

[0046] 1. Drill several boreholes 3 in parallel in the middle of the coal seam 2 of the top-coal caving working face 1 in the coal mine. The diameter of the boreholes 3 is 65-75mm. The depth is 90 meters. In order to facilitate the discharge of drilling cuttings, the borehole 3 has an elevation angle of 1 to 2°; in order to prevent the coal walls at both ends of the fully mechanized caving face 1, the two ends of the working face 1 and the adjacent nearest borehole 3 The distance 5 is not less than 10m.

[0047] 2. Use an emulsion pump to inject inhibitor solution into each coal seam borehole 3;

[0048] The amount of inhibitor solution injected into each borehole 3 is determined according to the following formula:

[0049] Q=L·B·M·γ·ΔW·K (1)

[0050]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com