Adsorbent in use for separating heating element Cs, preparation and application

An adsorbent and element technology, which is applied in the post-processing field of high-level radioactive waste in the nuclear industry, can solve problems such as chromatography research and technological process that have not yet been reported, and achieve the effects of good identification ability, high adsorption capacity and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

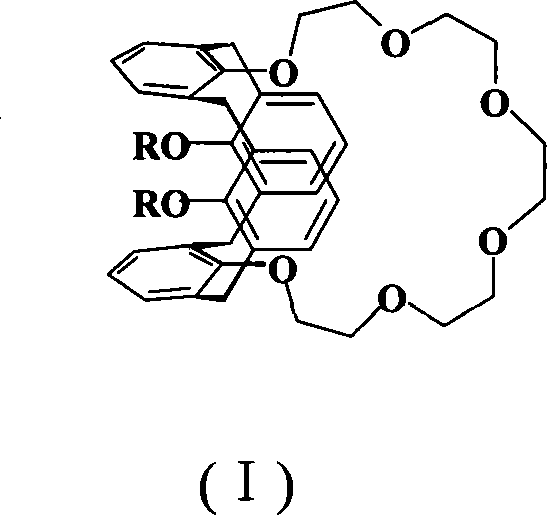

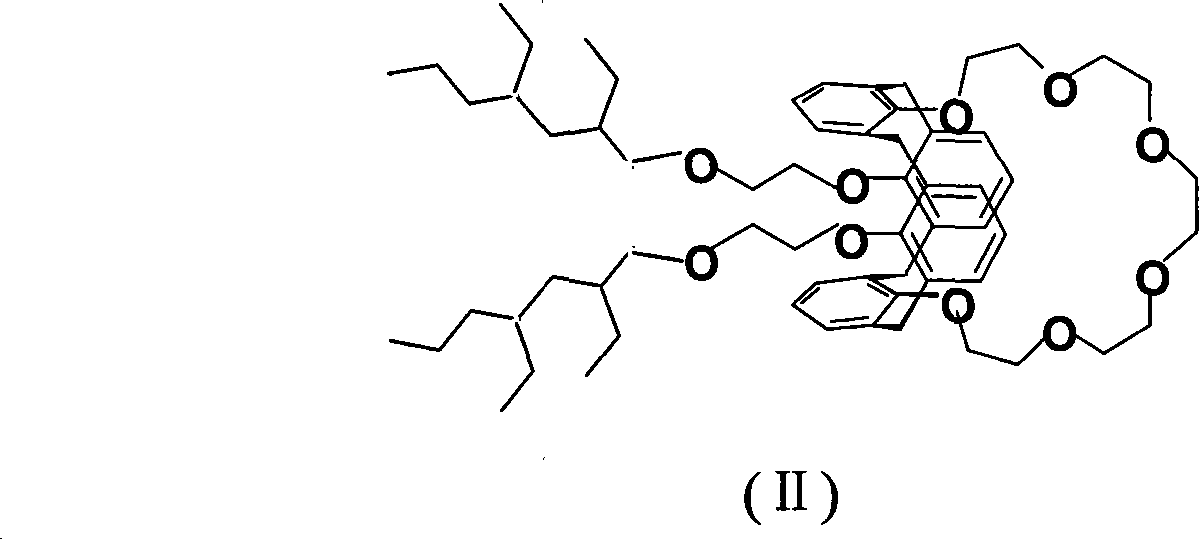

[0036] Embodiment 1 Adsorbent Calix[4]arene-R14 / SiO 2 - Preparation of P

[0037] Dissolve 100 g of Calix[4]arene-R14 (with structural formula (II)) and 60 g of tributylphosphate (TBP) in 500 mL of dichloromethane and mix well; add 200 g of polymer-coated macroporous SiO 2 (SiO 2 -P) Stir evenly to volatilize most of the dichloromethane until the material is in a nearly dry state, and then vacuum-dry the nearly dry material at 45° C. for 24 hours.

Embodiment 2

[0038] Example 2 Adsorbent Calix[4]arene-R14 / SiO 2 - Preparation of P

[0039] Dissolve 100 g of Calix[4]arene-R14 and 40 g of tributylphosphate (TBP) in 2000 mL of dichloromethane and mix well; add 1000 g of polymer-coated macroporous SiO 2 (SiO2-P) Stir evenly to volatilize most of the dichloromethane until the material is in a nearly dry state, and then dry the nearly dry material in vacuum at 45°C for 24 hours.

Embodiment 3

[0040] Example 3 Adsorbent Calix[4]arene-R14 / SiO 2 - Preparation of P

[0041] Dissolve 100 g of Calix[4]arene-R14 and 100 g of tributylphosphate (TBP) in 3000 mL of dichloromethane and mix well; add 1500 g of polymer-coated macroporous SiO 2 (SiO 2 -P) Stir evenly to volatilize most of the dichloromethane until the material is in a nearly dry state, and then vacuum-dry the nearly dry material at 45° C. for 24 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com