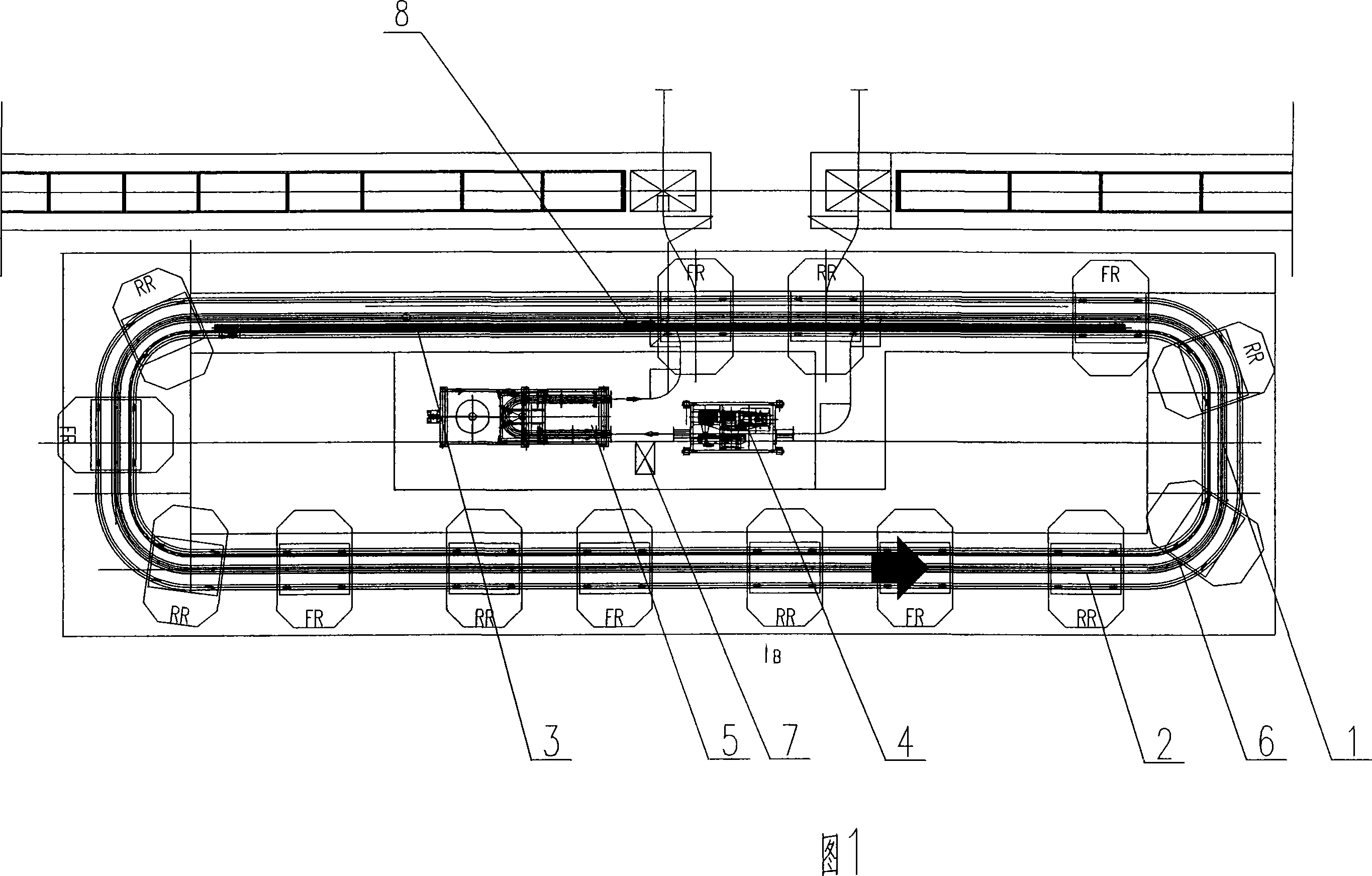

Annular front-rear axle variable stroke type conveying system

A conveying system, front and rear bridge technology, applied in conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of wasting working time and increasing labor intensity, and achieve a simple structure, reduce labor intensity, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

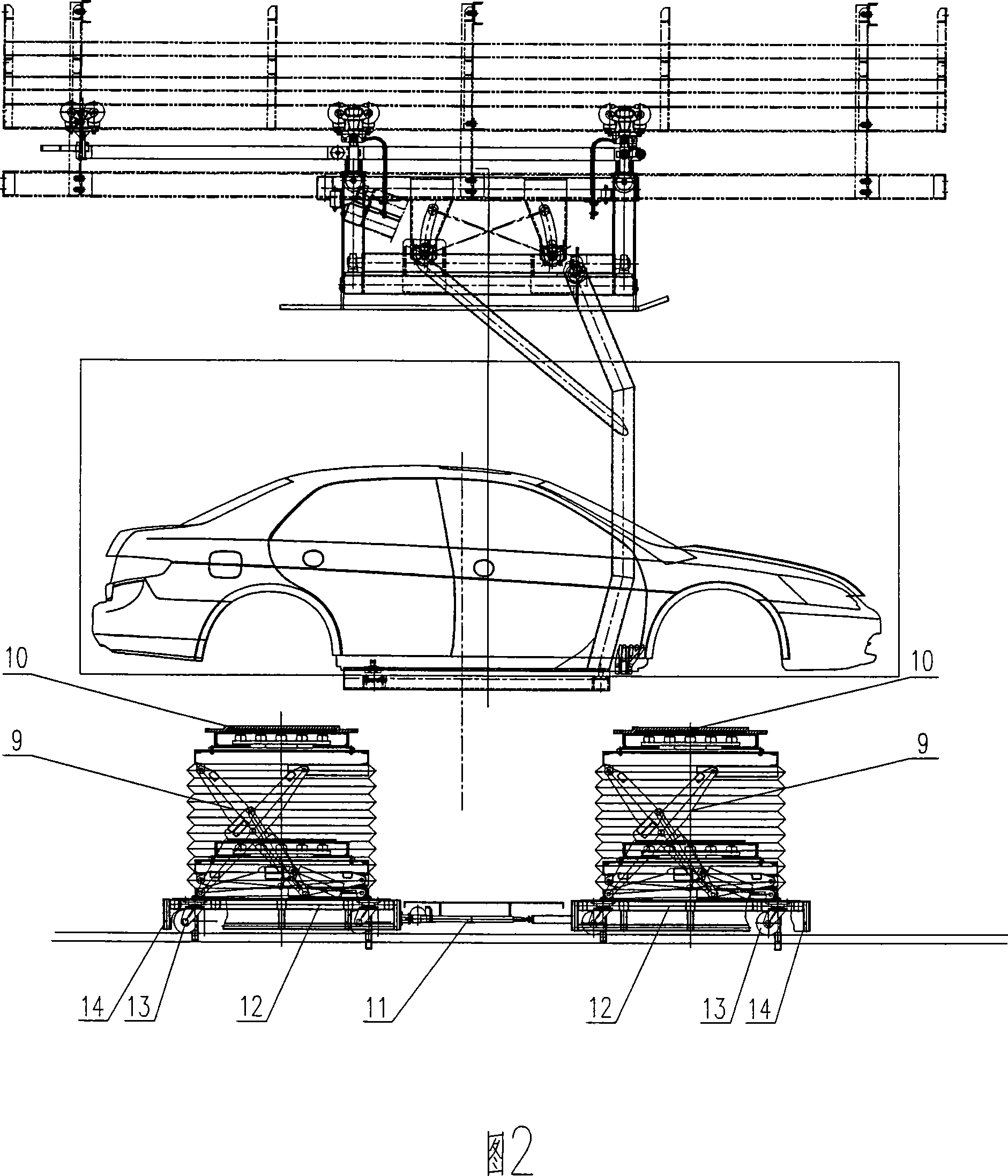

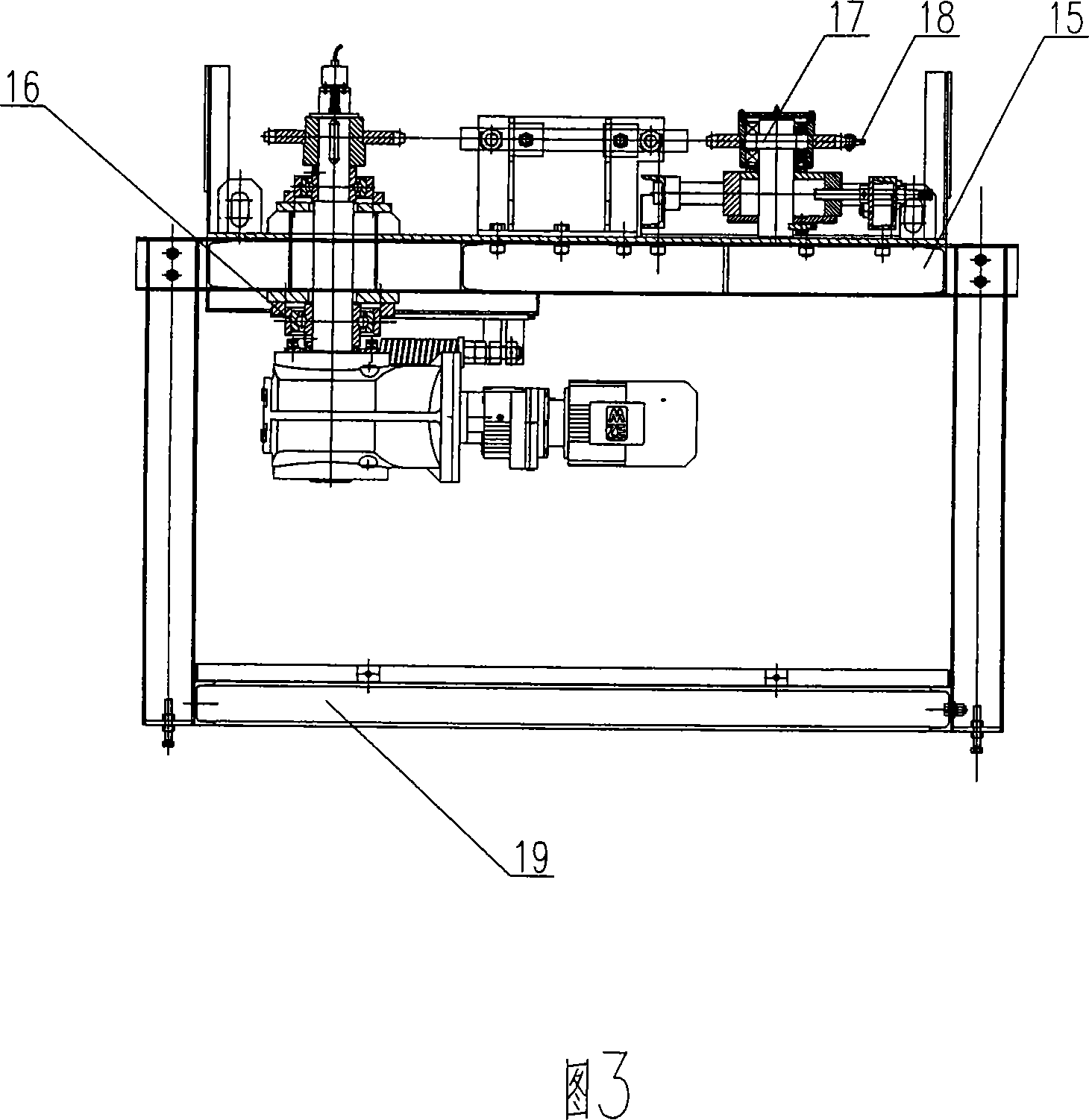

[0021] The present invention mainly consists of track 1, trolley 2, propulsion mechanism 3, driving device 4, tensioning device 5, chain 6, lubricating device 7, stopper 8, hydraulic jacking device 9, adjustable platform 10, electric push rod 11 , trolley support 12, universal wheel 13 and anti-collision mechanism 14 etc. are formed. Wherein, the driving frame 15 , the driving mechanism 16 , the tension wheel assembly 17 , the driving chain 18 and the underframe 19 etc. form the driving device 4 . Connecting track 20, tensioning frame 21, telescopic rail 22, tensioning curved rail 23, counterweight frame 24, counterweight 25, tensioning slide table 26 and fixed pulley assembly 27 etc. form tensioning device 5. Dolly 28, drive assembly 29, tension shaft assembly 30, support 31, chain 32, guide bar 33 and side plate 34 etc. form propulsion mechanism 3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com